@Darren - I have moved this topic away from the compliance module, as I find the subtopics to be more relevant here (Leading QA and Sustainable Pr). We can incorporate it at later stage. - Nat

Kia ora tatou LB6.

This small bite size module in your New Zealand Certificate in Construction Trades Supervision (Level 5) is looking at literature supporting correct quality codes of practice on site.

Our aim is this module is to:

- Implement quality practice without any sort of potential deficiency and effect on the environment.

Quality has been defined by many as “Delivering a service or product to a customer without any sort of defect being present or associated”.

To reach quality, it is important that any sort of code of practice or explanation documents, clearly set out the product specifications that is to then be required or followed.

These specifics or rules set out the standards of quality, that then can be described, prioritised, and measured precisely.

As referenced from the Building Performance website, it states that the Government building performance organization “encourage industry groups to create their own guidance and codes of practice for the use of their products. These need to complement and comply with our Acceptable Solutions and Verification Methods”.

Insert video here.

Manufactures’ Literature

Most reputable manufacturers publish their own literature relating to the function, specification, quality, installation and use of their products or materials.

Good manufacturer literature will contain a description of the product, where and how it can be used, how it can be stored, certain installation instructions, and the general warranty offered – according to the particular conditions stated.

When using manufacturers’ literature, you should ensure you are working with the latest version. Working from out-of-date information can be dangerous and a health and safety risk to you and others around you.

What is The Branz Code Mark?

The Branz “CodeMark” is a voluntary product certification scheme that provides all construction workers an easily understood and robust way to show the quality and designs of a building product which can be purchased.

This code mark reassures the purchaser the design or method meets the requirements of the New Zealand Building Code or the Building Code of Australia.

Branz itself is an internationally recognised organisation that provides advice and education on and around aspects of the construction industry.

Branz can help support quality and worksite practises within all aspects of the modern construction industry.

This Branz Code Mark is site appropriate for any building product, but it is particularly beneficial for manufacturers and suppliers to help endorse their construction product specifications.

By having a quality mark provides a greater marketing advantage, as certified products are deemed to comply with the appropriate Building Code solutions here and across the Tasman.

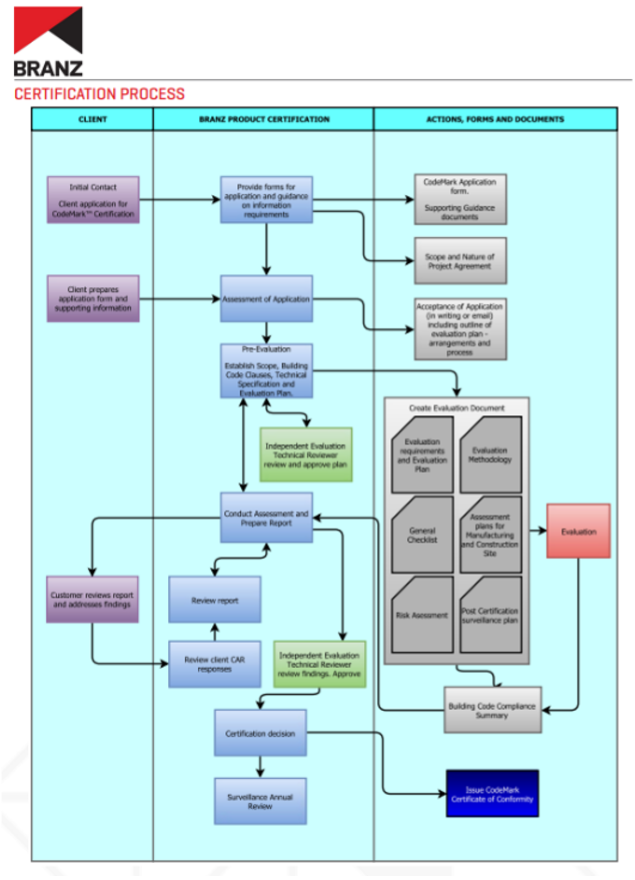

The following image taken from Branz NZ outlines the process to which the Codemark scheme on products goes through.

As well as providing reassurance on certain products, Branz also publish essential good practice resource guides for designers and builders.

These guides incorporate the requirements of codes and standards to provide the reader with a comprehensive overview of the required aspects needed.

These guides are just an example of the type of literature builders can use to ensure their quality performance on site. Branz also publish bulletins, building magazines and short builder’s mate news publications to help keep yours and the required standard up.

Have a look on the link below of the various Branz publication available:

https://www.branz.co.nz/shop/catalogue/category/good-practice-guide_6/

Branz Builders Mate is a great short easy to read publication giving advice on site, written by builders for builders.

Have a read of (publication stopped in February 2020 with the 100th edition) “Builder’s mate 100th”

https://www.branz.co.nz/pubs/builders-mate/

Insert activity here.

Insert video here.

Environmental Management Plan

In recent times, sustainability on the construction site has become part of growing importance in the purchasing of construction materials. This is because as statistics have shown, the construction industry is one of the largest single categories of waste going to landfill, and the industry is one of the largest producers of CO2 emissions.

Referenced from Branz “Construction and demolition waste accounts for over a third of all solid waste generated”

Local councils, clients and contractors may influence purchasing of certain goods by, for example, stipulating a minimum percentage of recycled materials.

A key purpose of the Building Act 2004 is that buildings are designed, constructed, and used in ways that promote sustainable development.

An Environmental Management Plan (EMP) is an essential tool for setting and managing environmental objectives for a construction project. Having an environmental plan will be part of an environmental management system (EMS) and will sit within documents prior to approval.

This EMP will include all the relevant Environmental policies and instruction set out prior to any work being constructed. The policy is a high-level statement of mission and principles in relation to environmental performance and quality.

The EMP plan is the key document in the environmental management system which sets out the projects detailed targets, objectives and procedures that will be adopted in order to achieve the goals set out in the environmental policy.

On small projects it may just form part of the brief, but on larger projects is likely to be a stand-alone document.

Part of creating an environmental plan would be to conduct a review of current procedures. This would normally be called an “environmental risk assessment”. This should be undertaken to help develop and outline information in the environmental plan. The environmental risk assessment will identify areas of environmental impact and potential carbon footprint risks.

Part of this assessment would include the use of harmful materials as well as the material sourcing/purchasing and their related transport costs.

Example, The construction industry uses plastic and polystyrene for a wide range of applications because of its general on-site versatility, insulation qualities, durability, corrosion and rot resistance, and strength to weight ratio, also Tight seals can be achieved with plastic making it suitable for use in adverse weather conditions.

A report that came out in 2019, “Rethinking Plastics in Aotearoa New Zealand” published by the Office of the Prime Minister’s Chief Science Advisor, states “construction globally is the second biggest user of plastics, and in this country the industry uses 15% of the plastic products manufactured here”.

Ref:Branz Level

The downside of this material is that only some plastics can be recycled. There are environmental concerns about some plastics because of difficulties when it comes to recycling them. There are also many concerns regarding the chemical additives used to make plastics flexible, resistant to fire, and adhesive in the first place.

We also use Polystyrene which is also widely used on construction sites in New Zealand. It speeds up the building times. However this material is considered extremely toxic and damaging to the natural environment.

Living ‘green’ and buying eco-friendly products creates and promotes a promising future not just for you but also for future generations.

As well as the product procurement we need to have awareness of the greenhouse gas emissions created during our construction.

The construction industry itself contributes to emissions from the energy used when buildings are occupied and when construction materials are extracted, processed, transported, and installed.

Taken from engineeringnz.org “Currently, the construction sector produces 20% of New Zealand’s carbon emissions”.

Building design and material selection both have a big role to play in the efforts to reduce greenhouse gas emissions. Many countries around the world, New Zealand included, have committed to reducing this greenhouse gas emissions.

A way Greenhouse gas emissions can be reduced in New Zealand’s residential and commercial buildings is through:

- Better energy management

- improved minimum performance standards for appliances used.

Taken from Branz NZ the construction sector can reduce these emissions through the result of:

- Improving Insulation levels

- Integrating renewable energy systems

- Supporting innovative green building design

- Retrofitting existing inefficient building stock

The “Climate Change Response Act 2002”, established in November 2019, set targets for New Zealand to reduce its admissions of all greenhouse gases to zero by 2050 so the building industry will be playing a big part in this response.

More information on your part towards positive environmental action can be found in the NZ standards website on ‘Environment Management systems’ (ISO 14001:2015)

This informative video from “Junkrun NZ” explains why polystyrene is so dangerous and what builders and construction site managers can do to reduce the pollution it causes.

Insert activity here.

Insert video here.

Quality Practices

Quality assurance is a set of planned and systematic actions to ensure that products and services comply with their specified requirements and rules. It not only involves checking the final quality of products to avoid defects, as is the case of quality control, but also assures product quality is checked in a planned, systematic way in all the production milestones.

Quality assurances is work practices to prevent errors from occurring in the first place. This is based on correct planning and implementation, backed up by quality manuals and or there required standards.

When a certain quality perspective has been reached outlining the required requirements, it is then possible to define these required elements in a series of generic standards applicable to any type of related practice. Remember we have already talked about these building standards previously

Quality Control on-site

In general this is when management ensures products and services comply with their set requirements.

Quality control is a work method that measures the quality characteristics of a specific item, it does this by comparing the required standard, and then analyses the differences between the results to then decide on corrective actions to obtain better results.

One way builders can control quality is based on the inspection or verification of the finished milestone.

The goal of these inspections is to filter the practice before it then reaches the client. Two common types of inspections are:

- Progressive inspections.

- Final inspection /Sign off.

(more could require depending on project circumstances)

Products that do not comply with their own set of requirements are corrected or altered to then be met. A downside to this, is that this could then lead to a higher cost for the company or business in term of materials or workmanship hours.

What documentations support Quality Assurances?

But before any construction project can commence, certain documentation, with its relevant specifications, needs to be ascertained.

Within these documents certain quality aspects and rules needs to be covered and documented.

The Plans and Specifications that accompany any project are a means of communicating between all parties involved in the building project, to adhere to current code of practice, while upholding the required building standard.

These Plans and Specifications for building work are required to show compliance with their functional and performance requirements to which will meet the building code. This in turn means that the building consent can be obtained and granted under the terms of the Building Act.

Plans and specifications can be generally broken down into four accompanying documents which will help guarantee the project’s quality within its construction.

- Specifications

- Any other supporting documentations

- working drawings or consented drawings

- structural calculations

These Plans and specifications also allow for the work to be Accurately priced and estimated in terms of time frames.

As well as correctly constructed as envisioned by the designer and according to the contractual agreement between the owner and the builder.

Insert activity here.

Differentiate New Zealand consumer protection warranties.

New Zealand’s building regulatory system is built on the Building Act 2004 and anchored by our performance-based Building Code.

This framework structure provides for the regulation of buildings, the building work carried out and various occupational groups in the building industry.

Even on the simplest of building project, you will have to interact with other parties, each party having their own roles and responsibilities associated.

The success or failure of a project often depends on how well people understand their own as well as other parties roles and responsibilities.

INSERT VIDEO HERE.

Warranties

A warranty is an assurance or guarantee from a seller of a provider that the goods/service offered will meet certain standards.

If for some reason the product or service doesn’t meet the standards offered, then the consumer can recover damages from that seller or provider.

Taken from the building performance website “The Building Act sets out implied warranties to protect residential building work whether there is a contract or not”.

In other words when something is implied it is automatic and agreed to without necessarily being talked about.

Written within the building act it outlines the length of the term implied warranties cover the work of a builder. This applies to the work and the materials that are used over the stated period of cover.

A basic example of this in practice would be:

Even though the builder does not say so, if the door does not swing properly, it should be fixed.

A link of implied warranties and defects have been provided for you after this video.

With build projects not only being protected by the implied warranties, there are other acts that also protect us as builders or clients, some of which isn’t solely based in and around the building industry.

Firstly is the Construction Contracts Act 2002

This Act in general terms guarantees support for the construction project workers contracts, these contracts are often in a standard contract form which means that parties involved would use a pre-printed agreement rather than negotiating their own terms, with elements aligning with the Construction Contracts Act 2002.

The purpose of this Act is to ensure fair and equitable procedures for regular and timely payment for construction work carried out.

This Act protects contractors and subcontractors against unfair payment terms and payment practices.

It also provides remedies for recovering money, and a quick, easy method for resolving payment disputes.it also outlines:

Consumer Guarantees Act

Then we have the Consumer Guarantees Act which applies to services provided by the building industry but not to buildings and building materials themselves as these are covered by the Building Act through the implied warranties structure.

Then we have the Fair Trading Act 1986

Taken from the consumer protection government website The Fair-Trading Act applies to all people in or carrying out a business.

There is nothing you can say or do to “contract out” of the Fair-Trading Act.

To clarify, this act “prohibits the use of certain types of false and misleading representations about the goods and services”, basically prohibits any unfair practices.

By a way of explaining the effect of the Fair-Trading act on the construction building services would be like:

You or your business must not mislead or deceive clients intentionally or accidentally.

You must be truthful about any claims you make about your services or the materials that you will provide for the project.

And you must be fair in our dealings with the client.

You can find a lot of information on this Fair-Trading Act as well as other consumer laws on the MBIE consumer protection.govt.nz web site.

Implied warranty as well as these Acts covered are all intended to safeguard construction practices on-site.

Further information on the Implied warranties and the construction contract Act can be read about in detail on the Building Performance website:

Information on construction contracts: https://tinyurl.com/3y64jvyb

Information on Implied warranty and defects: https://tinyurl.com/4add2v8w