Builders are required to carry out work health and safety procedures to protect the welfare of all their workers and site visitors. In general, builders will have a specific team take on the duty to manage work health and safety. However, the duty to take reasonable care for their own health and safety and that of others who may be affected by their actions or omissions applies to everyone in the workplace. Every person in the construction site must be responsible in ensuring workplace safety.

As a supervisor, you must see to it that the welfare of the workers is prioritised on site through the implementation of work health and safety (WHS) guidelines. Safety procedures in the workplace secure the workers, their productivity, and the quality of their work. As a supervisor, you must:

- Be familiar with general WHS requirements in construction;

- Coordinate with the Safety Manager and Safety Officers in developing and implementing WHS procedures;

- Be familiar with the WHS duty of care to properly coordinate with relevant people;

- Relay site-specific WHS measures to onsite staff;

- Be able to execute workplace inspections, identify hazards, and assess and control risks; and

- Rectify unsafe working conditions and correct improper and unsafe work activities.

As a supervisor managing construction work on site, you will be placed in a key position for the implementation of WHS procedures and will be obliged to lead by example in promoting safety in the workplace.

All construction personnel are required to undergo general construction induction training and obtain a White Card before they can be allowed to work in a construction site. For this unit of competency, it is expected that you have undergone the training and already know the basic WHS practices in the construction site. As such, the section will briefly review WHS concepts for this section and focus on applying them in construction.

Work Health and Safety Requirements Onsite

The Work Health and Safety Act 2011 (WHS Act) is the primary legislation that stipulates the framework to protect the health, safety and welfare of all workers and others in relation to workplaces and work activities.

The WHS Act establishes the requirements for the following:

- incident notification

- consultation with workers

- issue resolution

- inspector powers and functions

- offences and penalties

Duty of Care

Whose duty is it to ensure safety in the workplace?

Everyone has a duty of care to make sure that the workplace is safe. The WHS Act places the primary health and safety duty on a person conducting a business or undertaking (PCBU). The PCBU must ensure, so far as is reasonably practicable, the health and safety of workers at the workplace. Duties are also placed on officers of a PCBU, workers and other persons at a workplace.

Who has health and safety duties relating in a construction work?

Everyone involved in construction work has health and safety duties when carrying out the work. Specific duties for persons involved in construction will be detailed in the discussions that follow.

Persons Conducting a Business or Undertaking (PCBUs)

A PCBU has a primary duty of care to ensure the health and safety of workers while they are at work in the business or undertaking and others who may be affected by the carrying out of work, such as visitors. Specifically, PCBUs are required, so far as reasonably practicable, to ensure the:

- provision and maintenance of a safe work environment;

- provision and maintenance of safe plant and structures;

- provision and maintenance of safe systems of work;

- safe use, handling and storage of plant, structures and substances;

- provision of accessible and adequate facilities (for example access to washrooms, lockers and dining areas);

- provision of any instruction, training, information and supervision;

- monitoring of workers health and conditions at the workplace; and

- maintenance of any accommodation owned or under their management and control to ensure the health and safety of workers occupying the premises.

Take note that there may be, and usually are, multiple PCBUs handling the same task or responsibility, such as contractors and suppliers. When there are multiple PCBUs for the same activity, it is best to regularly consult, coordinate and cooperate with each other to perform your duties in relation to the same tasks.

Officers

Officers have a duty under the WHS Act to exercise due diligence to ensure the PCBU meets its duties to protect workers and other persons against harm to health and safety. Officers can do this by:

- possessing substantial knowledge on WHS matters

- applying risk management processes to the PCBU’s operations

- ensuring that the PCBU has appropriate systems of work in place

- assisting in monitoring and evaluation of WHS management processes

Workers

Workers in construction include direct employees, subcontractors and employees of subcontractors, employees of labour hire companies and apprentices. In compliance with the WHS Act, workers must always:

- take reasonable care for their own health and safety;

- take reasonable care their acts or omissions do not adversely affect the health and safety of other persons;

- comply with any reasonable instruction that is given by PCBUs to allow workers to comply with the WHS Act; and

- cooperate with any reasonable policy or procedure relating to health and safety at the workplace that the PCBU has notified workers of.

Other Persons

Other persons at the workplace, such as statutory authorities, certifiers, inspectors and visitors (e.g. owners and stakeholders), have a duty to:

- take reasonable care for their own health and safety

- take reasonable care their acts or omissions do not adversely affect the health and safety of other persons, and

- comply, so far as is reasonably practicable, with any reasonable instruction given to them by the PCBU.

When entering contracts, PCBUs must clearly communicate their safety requirements and policies, review the job to be undertaken, discuss any safety issues that may arise and how they will be dealt with. PCBUs must remember that while work health and safety responsibilities may be shared, these responsibilities cannot be transferred to another person.

Risk Management

Risk management is a proactive process that helps builders effectively manage the construction work. It must be systematic and must cover all reasonably foreseeable hazards and associated risks (Safe Work Australia, 2018). The risk management involves four step-by-step processes, as illustrated in the diagram to the left.

Hazard Identification

The first step in the risk management process is to identify the hazards associated with construction work. Hazards in the workplace can be identified by inspecting the workplace, consulting workers, subcontractors, and suppliers, and reviewing available information. In a construction site, typical hazards include:

- potential for electric shock, immersion or engulfment, fire or explosion

- potential slips, trips and falls

- possibility of being struck by moving plant

- exposure to noise, heat, cold, vibration, radiation including solar UV radiation

- use of ladders, incorrectly erected equipment, and unstable scaffolding

- unguarded holes, penetrations and voids, and excavations

- fragile and brittle surfaces such as cement sheet roofs, fibreglass roofs, skylights and unprotected formwork decks

- falling objects, for example tools, debris and equipment

- collapse of trenches and structure

- handling, use, storage, and transport or disposal of hazardous chemicals

- presence of asbestos and asbestos-containing materials

- welding fumes, gases and arcs

- hazardous manual tasks; interface with other works or trade activities

Risk Assessment

After hazards have been identified, the risks associated with these hazards must be assessed. In general, assessing the risk involves considering the severity of any injury or illness that could occur (consequence) and the likelihood or chance someone will suffer an illness or injury.

|

|

|

|||||

|

|

|

Insignificant |

Minor |

Moderate |

Major |

Severe |

|

Likelihood |

Almost certain |

Medium |

High |

High |

Extreme |

Extreme |

|

Likely |

Medium |

Medium |

High |

Extreme |

Extreme |

|

|

Possible |

Low |

Medium |

Medium |

High |

Extreme |

|

|

Unlikely |

Low |

Low |

Medium |

High |

High |

|

|

Rare |

Low |

Low |

Low |

Medium |

High |

|

To assess the severity of harm associated with each hazard you should consider the following questions:

- What type of harm could occur? Can the hazard cause death, serious injuries, illness or only minor injuries?

- What factors could influence the severity of harm that occurs? For example, the height from which a person might fall would affect the severity of the injury.

- Is the harm immediate or gradual? Some hazards like slips and falls cause immediate harm while others tend to cause more gradual harm like auditory damage due to constant noise exposure.

- Will specific tools or procedures be needed to assess the severity of the harm? This may involve laboratory tests and other tests like assessing the amount of noise exposure.

- How many people are exposed to the hazard? How many people could be harmed? For example, an explosion in a construction site may cause injury to many people including those outside the work area.

- Could one failure lead to other failures? For example, could the failure of your electrical supply make any control measures that rely on electricity ineffective?

- Could a small event escalate to a much larger event with more serious consequences? For example, a minor fire can get out of control quickly in the presence of large amounts of combustible materials.

On the other hand, the likelihood of harm can be assessed by considering the following questions:

- How often is the task done? Does this make the harm more or less likely?

- How often are people near the hazard? How close do people get to it?

- Has it ever happened before, either in your workplace or somewhere else? How often?

Since many hazards and their associated risks in the construction industry are well known and have well established and accepted control measures, formally assessing the risk for those hazards is not required anymore.

Still, there are hazards with unidentified risks that should be considered for risk assessment. Do not assume that all hazards in construction have been defined as hazards and their risks vary greatly from project to project. Other hazards (e.g. noise, airborne contaminants) require further scientific testing and measurement (mostly done by specialised workers) to assess the risks accurately.

Meanwhile, high risk work as outlined in the WHS Regulations requires formal risk assessment to be conducted under the same regulations.

Risk Control

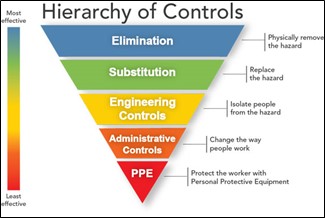

In controlling risks, there is a certain system to be followed, based on the level of protection and reliability a control measure gives. This is known as the hierarchy of control. The hierarchy ranks risks controls from the highest level to lowest level of protection and reliability. In general, the higher order controls must be considered first. The figure below shows the hierarchy.

In many cases a combination of control measures may be implemented to control a risk. For example, to manage the risk of workers getting strained or injured from lifting heavy loads, control measures may include:

- Elimination: Use of robotic technology, vehicles and other plant and equipment to eliminate the need to lift heavy items

- Substitution: Substitute heavy items with lighter materials with same quality and durability

- Engineering control: Usage of trolleys, lifts and other similar tools to aid workers in transporting heavy loads

- Administrative control: Training and supervision in proper lifting of materials, as well as health check-ups for workers

- PPE: Proper work clothes, as well as appropriate size for PPEs (e.g. safety shoes, helmet) for safety and ease of lifting

When selecting and implementing a combination of control measures it is important to consider whether any new risks might be introduced as a result and, if so, whether the combination of the control measures should be reviewed.

Review of Control Measures

The control measures implemented in the workplace should be reviewed regularly to make sure they work as planned. A review of the control measures is required:

- When control measures are no longer effective in controlling the risk;

- Before a change is about to take place at the workplace and is likely to give new or different health and safety risks that the control measures may not effectively control;

- If a new hazard or risk is identified;

- If results of consultation indicate that a review is necessary; or

- If a health and safety representative requests a review.

You can conduct a review of control measures through carrying out inspections, consulting PCBUs and other relevant persons, testing and evaluating records and data. Review of controls also involves using risk management process again for new hazards and risks.

Safety requirements and project administration procedures during onsite visits

As a supervisor, your responsibility to ensure that the WHS guidelines and all administrative procedures are implemented on site will not be exclusive to overseeing the workers but will include watching over site visitors as well. In general, it is your responsibility to look out for the welfare of everyone on site, regardless of their affiliation.

Site visitors, while not part of the site construction team, must observe all rules and precautions implemented on the site. Site visitors include clients or their representatives, external party inspectors, authorities, and suppliers.

In order to ensure safety during site visits, you must:

Coordinate with the visiting party beforehand

Most site visits will be scheduled, and you will be informed about it in advance. Before the site visit, relay the safety guidelines implemented on site to the visiting party via. Remind them of important instructions, such as ‘wear closed shoes’, ‘bring hard hats’, ‘no smoking within the area’, etc. Also, confirm the number of people who will be visiting beforehand in order to have an idea on how site activities will be affected by the visit. It is best to do this through email and back it up with a phone call.

Plan how site activities will be managed, considering the presence of visitors

Some visits may interfere with work, for example, visits from inspectors and representatives from testing laboratories who will be conducting necessary activities. You need to plan the activities so that productivity will still be optimum. With this, you need to develop, implement and provide a site safety plan.

A site safety plan provides detailed information of the construction site as well as site safety and organisational requirements to those who are within the premises of the site. Locations of specific areas such as restricted areas, emergency and first aid facilities, fire safety equipment, and evacuation routes and areas are marked. Safety and emergency procedures as well as contacts are also indicated. These pieces of information should be provided to those entering the site for their awareness of safety requirements onsite.

Give the visitors an orientation of the site policies and activities before they enter the actual working area

You may use the site office or a designated holding area to give the visitors a brief site induction. Explain the hazards and risks associated with the ongoing work and reinforce the rules stated in communication prior to the site visit. Make sure to cover the items in the Visitor Induction Checklist from Safe Work Australia.

Make sure the visitors adhere to safety and administrative regulations

Some safety and administrative requirements on site may include:

|

Safety requirements |

Administrative requirements |

|

Visitors must wear proper PPE before entering site premises. |

Visitors must log their details before entering site premises. |

|

Visitors must surrender all sharp or flammable implements before entering site premises. |

Visitors must always wear their IDs/passes while inside the site premises. |

|

Visitors are only allowed to go to specific areas and are not allowed to enter identified “no-go” zones. |

Visitors must sign documents stating that they have been properly inducted and made aware of the hazards present and rules implemented on site. |

|

Visitors must comply with all relevant instructions from the safety officer and the site supervisor. |

Visitors must be able to present proper documentation (e.g. authorisation, inspection plans, etc.) related to their visit when required. |

Coordinate details of the visit with the WHS team and site administration team

This is done in order to better manage site activities and ensure implementation of necessary procedures.

Proper communication and planning are key to effectively implement safety requirements and administrative procedures to site visitors. As a supervisor, you need to be vigilant, as these visitors may not be familiar with the policies implemented on site. You need to be authoritative when giving instructions to visitors, but also show them proper courtesy. You also have to be approachable and reliable in addressing their questions.

Inspections are necessary procedures in construction that ensure that the work is being carried out according to standards, requirements, plans, and schedules. Inspections are done regularly, and as frequently as necessary to identify and rectify mistakes immediately.

In general, inspection activities are done to provide the client or relevant authorities an impartial assessment of the work done by the contractor. Typical inspection activities are carried out by a building or site inspector appointed by the client or the consultant while regulatory requirements (fire safety compliance, environmental policies compliance, etc.) are conducted by specific authorities.

However, while building inspectors are appointed by the client or authorities, contractors must nevertheless carry out their own inspection activities. Regular inspections will help contractors monitor their work closely and enable them to take immediate corrective measures. Internal inspection activities will give the contractor an overview of whether the project is progressing as scheduled or not.

As a supervisor, it will be your responsibility to carry out project monitoring inspection for your company, as you are already supervising the construction work. You must be knowledgeable of the planned project schedule and you must be able to utilise relevant checklists well.

Onsite inspection for project monitoring

It is important to regularly conduct inspection throughout key stages of the project in order to make sure that any mistakes will not be carried over to the next stage. Furthermore, these inspections also provide an assessment of work items that have already been completed and those that need rework. Consequently, these details will be vital in the preparation of progress reports and the overall assessment of the project progress.

The Queensland Building and Construction Commission (QBCC) recommends that inspections be done at the following stages:

- on completion of applicable structural stages of construction (i.e. footing, slab, frame and final)

- immediately prior to the commencement of significant non-structural stages of construction (e.g. at pre-paint, immediately prior to fixing stage, or immediately prior to plasterboard or cladding being fixed)

- immediately prior to the work being handed over to the consumer.

To effectively carry out a project monitoring inspection, you need to:

|

No. |

Activity |

|

01 |

Review the planned schedule. Know what works should be completed by what date. This will help you plan and schedule your regular inspection, as well as coordinate with the relevant people concerned. |

|

02 |

Be knowledgeable with the work you are inspecting. As a supervisor, you are expected to be knowledgeable with the work and trades involved in construction. In doing the inspection, make sure that you know what to look for in order to assess and properly note the conditions of the work (Has the work been completed satisfactorily? Does it need rework? Is it still in progress?) |

|

03 |

Schedule and conduct inspections regularly. Inspection schedules may be based on client requirements or company procedures. Schedule a time in the day or a day in the week, whichever is necessary, to conduct project monitoring inspection. |

|

04 |

Use inspection checklists. The inspection checklists previously developed during the planning stage must be used when conducting inspections. Use these checklists as guides in organising inspection activities so that all appropriate work items will be assessed. |

|

05 |

Formalise inspection results through reports. Reports must be made to reflect the progress monitoring inspection. These reports would be filed as part of the standard documentation procedures for the project. These reports will verify that the routine inspection has been done. Furthermore, these reports would serve as formal accounts of the amount of progress the project has achieved in regular periods of time. |

Inspection Checklist for Progress Monitoring

Construction checklists vary depending on their purpose. In general, the main concern of project monitoring checklists is to address whether the work item has been successfully completed or not. As such, the items on these checklists may be listed in chronological order or following the activities in the project planning schedule/Gantt chart.

Using checklists is quite straightforward. You will only have to read each item carefully, and then tick the appropriate box or column reflecting the condition of the work item or milestone.

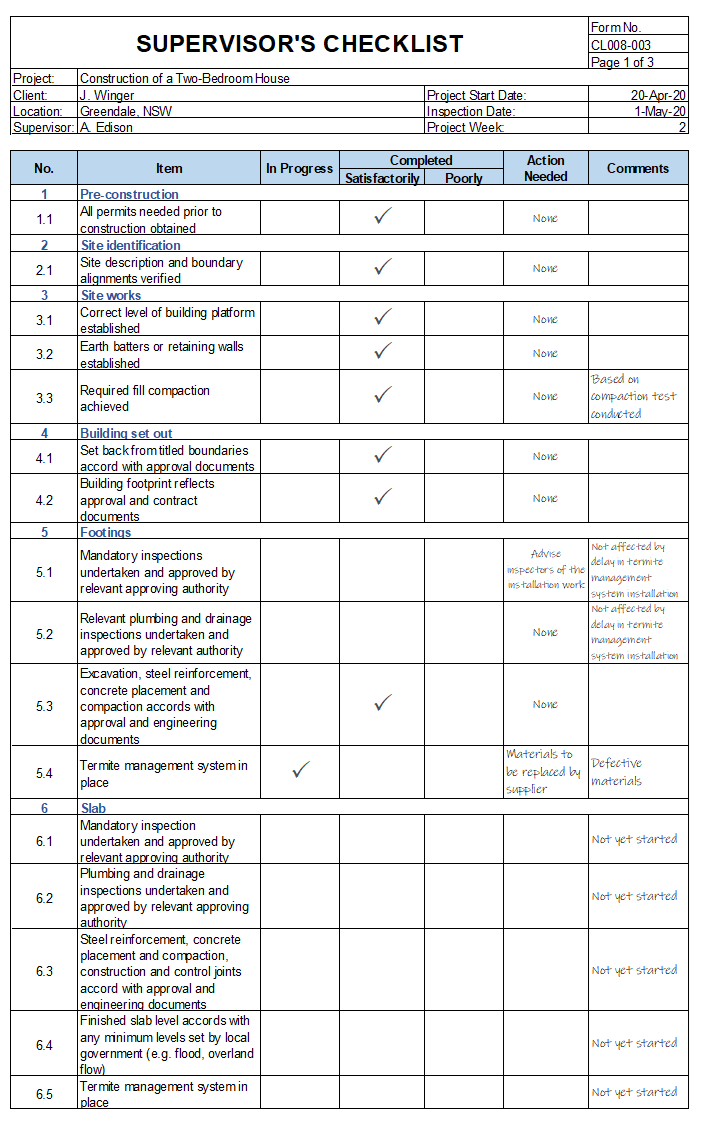

Case Study: Using progress monitoring checklists

Annie Edison had been appointed as supervisor for the construction of two-bedroom house in Greendale, New South Wales. To prepare for the routine progress inspection, she first consulted the project manager and checked the schedule of construction activities. From the schedule, it was expected that all the work for concrete footings must be completed by the end of the week, including installation of termite management system. Furthermore, external party inspection for footings would be conducted the following Monday.

Prior to the inspection, Annie noted the following conditions:

- All important documentation prior to the start of construction have been received and properly filed, including contract documents and permits.

- All site facilities are operational.

- Site has been cleared of debris.

- Necessary retaining walls have been completed.

Annie then conducted the site inspection on Friday afternoon and has noted the following:

All excavations in preparation for laying of foundations have been completed.

- Steel reinforcements for footings have been properly placed and laid out.

- Concrete mix for footings has been tested and strength has been found to be suitable.

- Concrete footings have already been curing for five days when the inspection was conducted.

- Installation of termite management system is in progress but has been delayed due to defective materials. Supplier has agreed to replace defective materials and installation will commence and be completed on the following Monday.

- The delay in the installation of termite management system will not affect the inspection that will be conducted by an external party on the following Monday, as the said inspection will focus on the structure of the footings.

As a result of the inspection, Annie accomplished the checklist as illustrated in the next page. She filled out necessary details in the document heading, including the date of inspection. She also noted which works in the checklist have not yet started. Annie wrote down relevant details in the checklist and eventually used them to guide her in writing the inspection report.

Inspection of work quality

Aside from tracking progress, routine inspections are also carried out largely to ensure that the materials and, consequently, the works comply to the contract requirements, relevant codes, and standards. As previously discussed, the quality of the materials and works must be frequently checked so that mistakes or defects can immediately be identified. After identifying defects or mistakes, relevant people must be notified through proper rectification notices so that corrective actions can be applied.

All mistakes or defects identified through inspection activities must be rectified as soon as possible to avoid delays in construction work and to make sure that they do not develop into more complex problems.

Quality control procedures will primarily be the responsibility of the quality control team. The duty to conduct quality control inspections will usually be held by the quality control inspector. However, some companies would prefer to maximise the organisational structure and would restructure all inspection tasks as part of supervision work. In these cases, supervisors may be asked to perform quality control inspection duties.

Therefore, as a supervisor, it is important to be familiar with the quality control procedures and to have a know-how on assessing whether a work or material is substandard. This knowledge and familiarity will enable you to supervise onsite construction work more effectively.

For this section, quality control inspection, recording quality of work, notifying relevant people, and issuing rectification notices will all be discussed. Note however that the inspection activities covered in this section will only pertain to those occurring while construction activities are still on going on site.

Quality Control Inspection

Quality control inspections generally revolve around the following:

|

|

|

| Construction materials | Plant | Labour |

Construction Materials

All materials delivered onsite must be fit to use for construction. It is the responsibility of the supervisor to make sure that the materials are free of defects and are standard-compliant prior to use.

Checking for material defects

Materials must be examined for any naturally occurring and/or manufactured defects prior to installation. As soon as the materials arrive on site, you must inspect them for any damages that may have occurred prior to or during transportation. Visual inspection procedures are usually appropriate for initial material checks. You will need to take note of the following indications:

- logos and markings related to quality (e.g. WaterMark logo for plumbing materials)

- cracks

- scratches

- dents, irregular bends and other malformations

If the materials are found to be defective and the extent of damage renders the materials unusable, the materials should be sent back to the supplier for replacement. However, if the defect is minor and does not compromise the function of the material, you may choose to record this and relay this information to the supplier to reach a resolution.

Comparison with specifications and standards

Materials must also be examined to check whether they meet contract document specifications and quality standards.

You need to look onto the documents that serve as evidence of suitability of the materials. For example, for steel materials, the supervisor may look to the Mill Test Certificate (MTC) or Mill Test Report (MTR) issued by the manufacturer and compare the details with the requirement. MTCs and MTRs provide information on the properties of a product and its compliance with the technical specifications. MTCs and MTRs may also indicate results of appropriate testing done on a product before it was delivered on site.

Some inspection activities would also require relevant testing procedures to be done to properly assess the quality of material. Checklists would often have items referring to testing procedures for materials. Thus, you must also be familiar with various material testing procedures. These tests quantitatively determine whether a certain material meets the standard requirements.

Different tests apply for different materials. Below are common testing procedures for different construction materials:

|

Material |

Tests |

Assessment for |

|

Bricks |

Compressive Strength Test |

Compressive strength |

|

Water absorption test |

Water absorption |

|

|

Efflorescence test |

Presence of alkalis |

|

|

Hardness test |

Hardness |

|

|

Size, shape, and colour test |

Uniformity |

|

|

Soundness Test |

Soundness |

|

|

Structure Test |

Brick structure |

|

|

Concrete |

Slump Test |

Consistency |

|

Concrete cylinder/cube test |

Compressive strength |

|

|

Rebound hammer test |

Compressive strength |

|

|

Penetration test |

Compressive strength |

|

|

Pull out test |

Compressive strength |

|

|

Ultrasonic Pulse Velocity (UPV) Test |

Compressive strength |

|

|

Sand |

Bulking test |

Increase in volume due to moisture |

|

Silt test |

Cleanliness of sand sample |

|

|

Steel |

Tensile strength test |

Tensile strength |

|

Brinell Hardness Test |

Hardness |

|

|

Radiographic testing |

Cracks and defects |

|

|

Ultrasonic Testing |

Cracks and defects |

|

|

Timber |

Oven dry testing |

Moisture content |

|

Moisture meter |

Moisture content |

All data and test results must be properly recorded and kept for the legal period required so that the information may be easily accessible and available for evaluation.

If the materials inspected or tested do not meet the specifications, they must be rejected and be replaced with compliant materials. After the delivered materials have been deemed acceptable for construction, they must be stored and stacked properly in order to avoid damages due to poor storage.

Plant, Equipment, and Tools

One of the conditions that contribute to producing quality work is the proper use and maintenance of plant, equipment, and tools. For example, in projects that require shotcrete procedures for concreting, the efficiency and quality of work would depend on the reliability of the shotcrete equipment and the skill of the operator.

Aside from warranting standard workmanship, proper use and maintenance of plant, equipment and tools also promote workplace health and safety, which is also necessary in ensuring the proper implementation of construction methodologies.

The plant, equipment and tools used during construction must be maintained in good working condition. In order to supervise maintenance and proper use of plant and tools you will have to:

- Access asset and tools inventory records and use them as guide for plant and tools inspection.

- Schedule regular inspections for plant, tools, and equipment.

- Check the maintenance records of the plant and equipment that will be used for the project.

- Coordinate with the project manager for upcoming maintenance schedules.

- Have a discussion with equipment operators for issues regarding tool and equipment use.

You must also oversee the storage of tools and equipment. As with materials, it is also important to store tools and equipment properly in order to maintain their good condition.

Labour

The construction workforce is a substantial factor defining the quality of work as construction is a highly collaborative process involving the collective effort of people from different trades and discipline. In order to maximise labour productivity, it is essential to maintain good supervision on workmanship and onsite working conditions.

Overseeing workmanship

As previously mentioned, the quality of work is also influenced by the skill of the worker. While experienced tradesmen are usually assigned for specific construction work, it would be reasonable for supervisors to exercise caution and check the workmanship.

Poor workmanship may lead to defects that may be ‘patent’ or ‘latent’.

Patent defects are defects that are identified after inspection and may include all defects discovered before the issuance of the certificate of completion. Latent defects, on the other hand, are defects that are not apparent after reasonable inspection, and usually cause problems after project completion.

An example of latent defect would be misplaced concrete reinforcement that eventually caused damage to structure. While latent defects may be caused by design or material failure apart from poor workmanship, it is best to minimise the possibility of these defects whenever possible. Supervision of various construction processes would be one way to curb such possibility.

Some common defects related to construction work include:

|

Construction Work |

Common Defects |

|

Earthworks |

Improper compaction levels |

|

Foundations |

Structural design defects |

|

Formwork |

Improper installation of formworks, defective formwork materials |

|

Concrete Work |

Cracking, surface blistering, curling of concrete slabs, honeycombing of concrete |

|

Structural Timber Frame |

Improper bracing, insufficient connections, substandard timber |

|

Reinforced Concrete Frame |

Poorly formed members due to improper installation of formwork, misplaced reinforcements |

|

Structural Steel Frame |

Poorly designed connections, poorly welded joints |

|

Floor Systems |

Cracking, buckling, abnormal gaps |

|

Roof System |

Roof leaks, unsecured flashings, sagging |

|

Masonry Construction |

Cracks in the materials used, poor mortar application |

|

Curtain Wall Construction |

Sealants and joint defects, water seepage and leaks, cracks |

|

Building Insulation |

Incorrect installation that cause water seepage |

|

Finishing |

Uneven finishing, insufficient surface preparation resulting to peeling, blistering or cracking of paint |

|

Waterproofing |

Leakage due to incorrect installation, defects due to poor design |

|

Electrical |

Faulty electrical wiring |

|

Plumbing |

Leaking pipes, pipe joint defects, improper installation |

|

HVAC |

Mechanical defects, ductwork problems |

As a supervisor, you must be knowledgeable in different construction trades so that you will be able to properly evaluate a process or finished work. You must also oversee rectification procedures when needed.

Work health and safety

As a supervisor, you must ensure that the health and safety of the workers are protected through the implementation of work health and safety (WHS) guidelines and that hazards are minimised in the workplace. When the health and safety of the workers are secured, they will be able to work more efficiently.

Although WHS guidelines will mainly be the responsibility of the WHS team, you will still have the duty to make sure that the workers under your supervision adhere to WHS policies. You must be watchful and make sure that the workers are properly wearing their PPEs, and that the PPEs they are using are not defective. You must also coordinate with the WHS inspectors to minimise hazards in the workplace and consequently have a working environment that will foster the delivery of good quality work.

Recording quality of work

All data gathered from inspection and testing must be properly documented. Section 3.2 has covered the development of effective recording systems and briefly discussed common means of documenting site activities like site diaries, written reports, and memoranda. This section, meanwhile, will discuss the different means of documentation used in recording the quality of work.

Recording the quality of work can be done during the inspection through checklists, and then after the inspection through formal reports and site diary logs.

Inspection Checklists

During inspection, you must always have the appropriate inspection checklist on hand. This will allow you to immediately record the conditions of work items specified in the checklist and jot down all relevant details including:

- All forms of defects identified for the work item

- The extent of defect and how it will affect other work items

- Action needed for a work item (e.g. repair or corrective action, material replacement, etc.)

- Delays

Using checklists is reasonably straightforward. Make sure to read each work item carefully and fill out the required details.

Written Reports

After the inspection checklist has been accomplished, you will have to use it as a basis to compose your written inspection report. You will essentially have to cover the same details recorded in the checklist (defects, needed action, delays, etc.) and present them in an organised manner. Aside from these details, you will also have to include the following in your report:

- Project details (Short description, client, location)

- Date of inspection

- Purpose of the inspection

- Conditions of inspection (Was the inspection purely visual? Were there tools used to aid the inspection?)

- Weather conditions

- Stage of Works

- Name of inspector

- Summary of findings

- Photographs of inspected work

In some cases, a rectification plan may be required to be attached with the report. Rectification plans are documents that cover how corrective actions will be carried out. Rectification plans will be discussed further at a later section.

For written reports, as with any form of documentation in construction, make sure to keep the contents straightforward.

Site Diary Logs

All important details gathered from the inspection and testing activities must be recorded in the site diary. The log should include a brief summary of the content of the inspection or testing report (results, defects identified, action needed), and references or links to the checklist used and corresponding report. Inspection and testing logs must also include the date, weather condition, and the name of the inspector or testing administrator.

Developing a rectification plan

After the inspection, works inspected will be deemed as either satisfactory or unsatisfactory. Works will be deemed unsatisfactory when they fail to meet quality benchmarks and specified requirements, and consequently, they will need to be rectified. Thus, a rectification plan must be developed to streamline the rectification process intended to correct a certain defect or unsatisfactory condition.

In developing a rectification plan, you must determine:

- The defect to be rectified and extent of defect

- Possible causes of defect

- Reasons for rectification

- The order of rectification procedures

- The expected duration of each rectification procedure

- The person in charge of rectification

- Any delays that will be caused by the rectification and relevant people to notify

Consider how these details are applied in the development of the rectification plan:

Case Study: Development of a rectification plan for defect in concrete work

Shirley Bennett is in charge of supervising the construction work for a three-bedroom, single storey residential project. Based on the working drawings and specifications for the project, a concrete wall is built between Bedroom 1 and the adjacent bathroom.

After conducting an inspection on the recently completed interior concrete wall, she found honeycombed areas on both sides of the wall. Shirley immediately called the attention of the structural engineer, and a non-destructive test was conducted to determine the extent of the damage. According to the test results, the honeycombing was a surface defect only and the reinforcements were not affected by it. Since the honeycombing does not affect the structural integrity of the wall, Shirley knew that the rectification procedure will be simple. However, the rectification procedure will still cause delays in the surface and preparation painting works on the side of Bedroom 1 and the waterproofing and tiling works on the side of the bathroom.

Based on the available details, she was able to develop the following outline for a rectification plan:

1. Defect to be rectified:

Honeycombing in various sections of the concrete wall between Bedroom 1 and in the adjacent bathroom.

2. Extent of defect: Shallow, does not affect reinforcements

3. Possible causes of defect:

a. Poor workability of concrete mix

b. Poor formwork installation or poor formwork material

c. Improper vibration

4. Why should the defect be rectified?

Even though it does not affect the structural integrity of the wall negatively, a honeycombed concrete wall is still considered substandard.

Surface preparation, painting, waterproofing, and tiling works cannot be started for the affected walls unless honeycombing is rectified.

5. How should the defect be rectified? How long will the rectification take?

|

Procedure |

Estimated duration |

|

With high pressure water blasting or with a chipping hammer, remove lightly attached stones, loose aggregates and concrete pieces from the honeycombed area. |

1 hour |

|

Remove smaller pieces of concrete and concrete dust from the honeycombed area by using compressed air or by washing with water. |

1 hour |

|

Prepare and mix the mortar for filling up the honeycombed area. (Note: mortar must be made from the same materials as the original concrete or equivalent material approved by the engineer) |

2 hours |

|

Carefully fill the cavity, layer by layer, with the mortar until the cavity is slightly overfilled. |

1.5 hours |

|

Level the surface to the required shape and finish it smoothly. |

0.5 hour |

|

Allow the patched area to harden in a few hours and cure for 7 days. |

5 hours hardening, 7 days curing |

6. Who will rectify this defect?

Concrete masons: A. Osborne, R. Stephenson

7. Delays related to this rectification work and people to notify:

|

Work Affected |

Delayed By |

Concerned Party |

|

Surface preparation |

1 day |

Painting contractor |

|

Painting |

2 days |

Painting contractor |

|

Waterproofing |

2 days |

Waterproofing contractor |

|

Tiling |

3 days |

Tiling contractor |

Notifying relevant people of defects

After inspections have been conducted and defects have been identified, you must notify relevant people who need to take action or those who need to consider the impact of these defects with regard to other works or the overall progress of the project.

Who will you notify for defects and rectification?

People in charge of the defective work

After the inspection, you will have to communicate with the people in charge of the work you have found to be defective. You will have to notify them of the defects you found after inspection and have a deliberation with them about the possible causes or procedure errors that may have led to the defect. You may also ask for their input on how the defect could be corrected, as in most cases, they will also be responsible for rectifying the defective work.

People in charge of rectifying defects

After discussing the possible causes of defects and outlining the rectification procedure, you will have to coordinate with the people in charge of rectifying the work. As mentioned previously, people who are tasked to rectify defective work will usually come from the same group of people who were previously assigned to the work as a form of keeping accountability. In such cases, the implementation of rectification procedures is expected to run smooth as the workers will already be knowledgeable of the work.

In cases when the client or the management decides that the rectification procedures be assigned to a different group of people, you will have to make sure that this group will be sufficiently informed of the details related to the defect. You will have to relay the rectification plan to them as well as inform them of target schedules. You will also have to make sure that they have clearly understood the rectification procedures intended to correct the defect.

People in charge of other work affected by the defect

Often, a defect in one work or procedure will affect the schedule of the following work, and consequently, the schedule of the entire project. You need to identify which works will be affected by an identified defect and intended rectification process and then coordinate with the people responsible for these works. You must immediately inform them of the changes in schedule so that they will be able to make adjustments on their end, especially for subcontracted works.

Project Manager

The project manager is in charge of all matters related to the project and must therefore be informed of any defects and rectification procedures. This will help the project manager plan necessary adjustments in the project schedule.

Client

Clients are usually informed of defects and rectification that occur in the middle of the construction process through regular progress reports and during their scheduled visits. As the owners of the project, clients are entitled to be informed and updated with any defects and rectification plans during construction.

Issuing a rectification notice

A rectification notice or a notice of unsatisfactory work must be issued to the relevant group of workers or subcontractors to formally notify them of the defects and compel them to take corrective action. The rectification notice or notice of unsatisfactory work must cover the following:

- What defect has been identified?

- Where was the defect identified?

- What corrective action is expected from the relevant group of workers/subcontractors?

- A request directed to the relevant group of workers/subcontractors requiring them to provide their proposed timeframe and procedures for rectification.

The issuance of this notice must be logged in the site diaries, and a copy of this notice must be kept and filed properly. Notices pertaining to unsatisfactory work and rectification are useful in establishing liabilities and settling payment claim disputes, especially over subcontracted work. Subcontractors are expected to achieve the quality of work agreed upon and must therefore rectify any substandard work.

The same would apply if the contractor received a notice of unsatisfactory work from the owner or owner’s representative. The contractor must keep the notice properly and immediately rectify the problem so that it meets the standards necessary for the work.

Once rectification procedures have been commenced, monitoring of the rectified work is necessary to ensure that the work is finally compliant with organisational quality control requirements, building standards and client satisfaction. Therefore, it is important that you develop systems to be able to monitor rectified work.

Inspection of rectified work

As a supervisor, it will be your duty to verify, through a series (or a system) of inspection activities, that the proper rectification has been done and previously identified defects have been eliminated.

To effectively inspect rectified work, you must:

- Review quality control benchmarks. Review organisational and regulatory quality requirements and pay attention to how these will apply to rectified work.

- Review previous inspection checklists and reports. Go through the previous checklists and reports to understand what went wrong in the previous work and what to look out for in the rectified work.

- Use appropriate checklist when inspecting rectified work. Make sure that the items in previous checklists are the same items covered in your checklist for inspecting rectified work. This will make it easier for you to have an ‘apple to apple’ comparison of the previous work and the rectified work.

- Determine whether rectification work has been satisfactorily completed. Evaluate whether the condition of the completed work is suitable and compliant with the requirements.

Assessment of Rectified Work

In assessing the rectified work, you will have to address the following:

Have the previously identified defects have been corrected?

You need to make sure that the rectification has fixed the defect and all the problems associated with it. Consider the following example:

After the inspection of the bathroom plumbing, the supervisor identified a leakage issue attributed to a cracked pipe. The supervisor coordinated with the plumbers and the pipe was replaced with a new, more durable one. However, while inspecting the rectified work, the supervisor found that the leakage issue persisted, this time due to insufficient joint sealing.

In this example, replacing the pipe has provided a solution for the crack in the previous pipe but did not completely solve the leakage issue.

Did the rectification cause another defect?

While the rectification done may have fixed the defect, you need to make sure that it did not create new problems or cause defects for other works. Consider the following example:

After the inspection, the supervisor has determined that the wrong type of insulation was installed on a brick wall. To rectify this, the wrong insulation material was removed and replaced with the correct one. However, the process of installing the new insulation caused damage to the brick wall. Before the installation of the new insulation material can be completed, the brick wall damage must first be repaired.

In this example, rectifying the error with the insulation material has unexpectedly caused damage to the adjacent brick wall. For this example, the brick wall damage must first be rectified, and caution must be taken in installing the insulation.

Is rectification sufficient to allow the next work to proceed?

You must assess whether the rectification work is enough to ensure that the next work will be carried out smoothly. Consider the following example:

A honeycombed surface in the concrete wall has been identified. This problem was immediately rectified, although it still caused delay with painting work. While inspecting the rectified area, the supervisor has noted that the cavity has been sufficiently filled and that the surface of the patch is level and flows smoothly with the rest of the concrete wall surface. With this, the supervisor notes that the surface preparation for painting the wall may now be conducted.

In this example, it has been established that the painting work for the wall cannot proceed unless the honeycombed area has been repaired. Therefore, after the rectification work has been done, the supervisor checked whether the rectified area is now suitable for the next work, which is surface preparation and painting.

Compliance with organisational quality control requirements, building standards and client satisfaction

Organisation quality control requirements

The project’s organisation primarily provides the quality control requirements necessary to deem rectification work approved and accepted. Apart from building standards (discussed next), your organisation may have additional requirements, such as compliance of materials and equipment used, training or skills a worker possesses and other factors that will ensure defects will not appear again.

Organisational requirements may also involve project management requirements such as the additional duration of work and costs incurred from the rectification work.

Building Standards

Rectified work should be also compliant with industry standards in the building and construction field. As discussed before, the Building Code of Australia (BCA) provides these standards on various aspects for multiple building classifications.

Aside from that, several Australian Standards, whether referenced from the BCA or not, also provide standards on building and construction quality that you should review in order to make sure that the newly rectified sections of the building comply with these standards, especially with regards to safety and structural integrity.

Client Satisfaction

Of course, the client should also feel that rectified work in the building has complied with their own standards. These standards, apart from the ones already mentioned, are indicated in the contract.

Therefore, part of monitoring and ensuring proper rectification work is to review the contract for specific requirements not stated in other standards and requirements.