This section will be examining how to assess the whole life cycle of materials and products while managing resource demand and consumption to ensure project plans incorporate minimisation strategies where waste management is concerned. When working in the construction industry resource demand, consumption over the life cycle of products can drastically impact the waste management strategy and is of utmost importance to remaining economical, efficient and compliant.

Assessment of whole of the life cycle of materials and products

A comprehensive waste management strategy will incorporate an assessment of materials and products used in the building and construction process. You now understand how procurement of material and products can impact the project's economical, efficient, and environmental impacts. When evaluating building and construction materials to identify high quality and more durable materials, select those that will extend the life of the structure. These materials will simplify future extensions and refurbishment. The procurement and or choice to integrate specific products and materials over lower-performing counterparts must consider the life cycle of each and integrated into the waste management plan.

“Life Cycle Assessment (LCA) is a technique for assessing the potential environmental aspects and potential aspects associated with a product (or service)” The assessment of the whole of the life cycle of materials and products follows these systems:

|

|

|

|

|

| Raw Material Resource Extraction | Manufacturing | Delivery and Transportation | Use, Maintenance and Repair | Disposal or Recycling |

The assessment of the whole life cycle of materials and products evaluates each of the systems mentioned above. It considers potential negative and positive environmental impacts for each.

Using the life cycle assessment (LCA) for checking the potential positive and negative environmental aspects associated with a product (or service) will require you to complete either a table or checklist. The LCA will summarise each product or service and integrate this into the waste management strategy. This assessment will require you to identify two life cycle stages of the product or material, assess the potential negative environmental impact at the stages they identified. Each assessment will vary depending on the construction method, materials used and client specifications.

The organisation known as Good Environmental Choice Australia (GECA) is an autonomous, not-for-profit organisation that runs the internationally recognised Environmental Choice Australia Ecolabelling Program, Green Tick®. The Green Tick program is based on a life cycle assessment (LCA) of the consequences of an operation down its supply chain. However, there are more programs the construction company can integrate into the waste management strategy depending on the project and company preferences. By integrating the life cycle assessment for materials and products being used in the construction project, one can determine each choice's impacts and make further amendments. A simple table can then be added to the waste management strategy demonstrating your preference for environmentally friendly building choices.

The table provided below is an example of an LCA in a scenario where timber will be used in the site while building a house.

|

The Aspect of Life Cycle Assessment |

Potential Negative Impacts |

|

Raw material resource extraction |

The potential negative environmental impact of the raw material's extraction is very low. The timber that will be used to create mud will be from the clearing for the house’s site, and they will use any from a different location. This will also minimise the waste generated during construction because they found a way to use the cleared timber instead of merely disposing of it in a landfill. |

|

Manufacturing |

The potential negative environmental impact of the manufacturing process is high. The supplier’s production plant is located at another site, and termite treatment of the timber can create pollutants form chemical formulas. |

|

Delivery and transportation |

The potential negative environmental impact of the manufacturing process is very high. The supplier’s production plant is located at another site, so transportation will create pollutants to be released and expensive for bulky transport. |

|

Use, maintenance and repair |

The negative impact of using timber from the construction site is relatively low in terms of use and maintenance. Although transport, manufacturing and treatment can produce a relatively higher impact on the environment, timber is considered a sustainable material preference. It will be unlikely to require minimal maintenance over the lifecycle. |

|

Disposal or recycling |

The potential negative environmental impact of timber at the end of its life is also very low. Recycling timber is typically very easy, and the materials can be used to create new building materials. This reduces the amount of waste disposed of in a landfill. |

Managing resource demand and consumption

The procurement and or choice to integrate individual products and materials over lower-performing counterparts must consider the life cycle of each and integrated into the waste management plan. Further to this, you must remember to manage resource demand and consumption to ensure accurate ordering can minimise waste. Evaluating building and construction materials over the life cycle will identify high quality and more durable materials that will extend the structure's life and simplify its future extension and refurbishment. Importantly, ordering less efficient products, overordering products, or obtaining more product than needed will result in accumulated waste, and this is a crucial factor for the waste management strategy.

When considering resource demand and consumption ensure that the building and construction materials you use are durable and of high quality. When materials you use are durable, and of high quality, this will strengthen your built product's sustainability and minimise waste across its life cycle. In particular, you will have to check for the following characteristics:

|

|

|

|

|

|

| Life Cycle certified by an accredited Scheme. e.g. Green Tick | Renewable over non-renewable or finite resources | Low in embodied energy | Certified as non threatening to biodiversity | Low toxicity in both production and operation | High in renewable, recycled or reclaimed content provided durability and performance are appropriate for life span |

The following steps can help minimise the negative environmental impact of a building and construction project:

- Examining similar past projects to see how many resources were used

- Making sure that the project only uses the allocated resources

By examining similar past projects, you can develop a somewhat accurate estimate of how much of a particular resource is needed for future projects. This research will enable you to prepare for the procurement process. If you can order what you need promptly, you avoid material degradation and the need to obtain more resources, which lessens the stress placed on the environment. These actions will also lead to fewer deliveries needed, which then leads to less air pollution.

Furthermore, by ensuring that the project only uses the allocated resources, you avoid having to obtain additional resources, meaning less raw materials will have to be extracted from the environment.

When managing materials procurement to minimise waste for construction features, consider using recycled materials where appropriate, that meet regulatory and standards' restrictions, and incorporate these waste minimisation strategies.

Recycling, reclaiming and reusing materials ensure project plans incorporate minimisation strategies where the waste management is concerned and manage environmental risks. When working in the construction industry recycling, reclaiming and reusing materials can drastically impact the waste management strategy and is of utmost importance to remaining economical, efficient and compliant.

Managing Environmental Risk

When taking steps to manage materials procurement, to minimise waste and recycling, it is essential to consider the environmental risks derived from sourcing, producing, and using certain products and materials. This information has been integrated with previous sections of this unit. However, a formal assessment is an important aspect of the waste management strategy.

An environmental risk assessment for a project integrating products and materials can take the shape of a general hazard risk assessment. Your workplace may have a template for an environmental risk assessment. This template can be rectified to determine environmental risks about waste management for products and materials and the risks this poses to the environment. Regardless of the template you use, this initial risk assessment can be later extended to include safe working protocols in waste management practices. Generally, this will be explored further in the next chapter.

When engaging with the waste management strategy, be aware of what environmentally responsible practices to would look for and ensure that the construction processes:

- Minimise negative environmental impact

- Promote sustainability

An environmental risk assessment allows you to assess your business's likelihood of causing harm to the environment. This assessment includes describing potential hazards and impacts before taking precautions to reduce the risks. Environmental risks should consider the risk to people from development, the risk to the environment from development and risks associated with chemicals and contaminated sites. Australia is home to many unique flora and fauna species, and it is essential to protect them. The Environment Protection and Biodiversity Conservation Act 1999 (EPBC Act) is Australia’s national environmental law. It makes sure that ‘nationally significant’ animals, plants, habitats and heritage places are detected, and any possible harmful impacts on them are considered, before land-use changes or new developments are approved. Generic information about risk assessment techniques is provided in the International Standard IEC/ISO 31010: 2009 “Risk management – Risk assessment techniques” (IEC, 2009); and the environmental risk management process outlined in the AS/NZS Handbook HB 203:2012 “Managing environment-related risk” (Standards Australia / Standards New Zealand, 2012).

Risk assessment

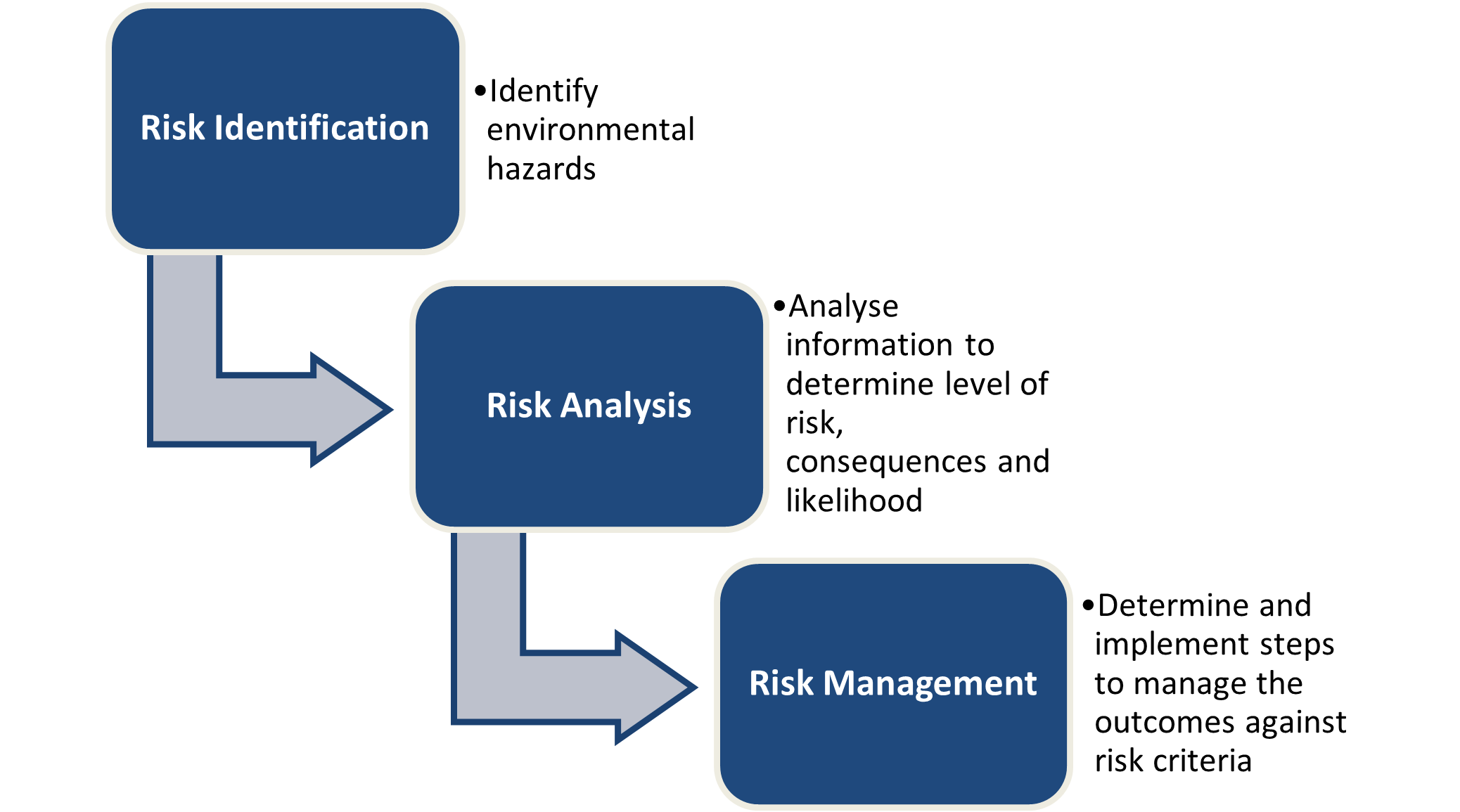

The three phases of a general environmental risk assessment include:

- Risk identification – including identifying products and chemicals being used, a hazard assessment and an exposure assessment

- Risk analysis – including developing an understanding of the level of risk for the product or chemical, identifying the consequence and the likelihood of the environmental risk eventuating

- Risk Management – identify ways to manage environmental risk and reduce waste.

A sample of an environmental risk assessment for soil erosion is displayed below.

A sample of an environmental risk assessment for soil erosion is displayed below.

|

Environmental risk |

Risk level, consequences and likelihood |

How to manage the risk |

|

Soil erosion |

The high-level risk to the environment, habitat and personnel. This is likely in construction requiring heavy foundations and earthworks. Also, dependant on flooding, soil type and slope. |

As much as possible, leave plants in place so that they can prevent the soil from eroding. The roots of plants keep the soil together, and the plant itself shelters the soil from wind that can cause erosion. |

Although reducing waste is the highest priority for the waste management plan, proper waste disposal includes making sure that any harmful waste does not leak into the environment. In some instances where the creation of waste by-products is unavoidable, these measures are even more necessary.

The department of agriculture, water and the environment list many processes which might impact the environment, including hazardous waste, gas emissions, chemicals, biotechnology, air quality, fuel qualities, and excess water use. Further to this, one might look at soil erosion, land contamination and excess litter.

For the construction site, some risk management techniques to reduce waste may include:

- implementing sustainability features specified in the design, reducing environmental impacts from building

- source and make use of recycled or reused materials

- access environmentally certified materials and order with ample lead time

- separate waste flows on site

- instruct and charge subcontractors who fail to use preferred environmental practices

- ensure that liquids, solvents and finishes are air quality friendly for indoors

- conserve on-site biodiversity

Now you have an idea of how to manage environmental risk, ensure you remember what environmentally responsible practices to look for and ensure that the construction processes minimise negative environmental impacts and promote sustainability.

Recycling, Reclaiming and Reusing Materials

Discussions around recycling have been increasing in recent times due to the planet's overwhelming concerns. This concern is extended to the building and construction industry and something you will need to become familiar with as future builders. Defining each of the terms: recycle, reclaim, and reuse will help ascertain which actions you can do.

|

Recycle |

Reclaim |

Reuse |

|

Break down and create something else. |

No breaking down but used for a different purpose. e.g. a door becomes a tabletop |

No breaking down, and use for the same purpose. |

When employing the recycling, reclaiming and reusing materials, to ensure project plans incorporate minimisation strategies where the waste management is concerned, you must identify if the material was recycled, reclaimed, or reused and consider how this promotes sustainability.

For example, concrete obtained from a demolition site is broken up into much smaller pieces, and these are sifted to remove any impurities. The broken-up concrete is then used as a base for a footpath paving project.

To ascertain how sustainability is enforced, you might ask:

- What happened to the material?

- How was sustainability promoted?

In this instance, sustainability was promoted by removing the need for new raw materials for the footpath paving project. Instead, they found a new way to use the concrete from the demolition site.

Therefore, when implementing the principles of recycling, reclaiming and reusing remember to ask yourself if a better option can be made, what that option is, and how can this promote sustainability. Take examples from the environmental risk assessment to look for more recycling options, reclaim, and reuse practices. Environmental risks which can implement recycling, reclaiming and reusing practices include, air quality, fuel qualities, and excess water use. Aside from these, you might look at soil erosion, land contamination and excess litter.

- reducing gas emmisions by reclaiming solar energy

- recycling water being used in and around the plant

- recaiming buidling materials to reduce waste and excess litter

- reusing excavation materials - for example, soil

- breaking down and recycling materials for building for example wood

The use of recycling, reclaiming and reusing principles in the construction project is pertinent to waste management by directly reducing waste. Although the option to integrate these principles seems quite the task for the overall project, as you begin to include these avenues, your clients, suppliers, and other stakeholders will appreciate your company's efforts. You will fewer minimal problems in remaining compliant with sustainability regulations.

This section will look at practical, efficient and economical procurement and specifications for packaging waste reduction. Further to this is engaging with environmentally responsible suppliers and how this can benefit project plans ensuring they incorporate minimisation strategies where the waste management is concerned. Working in the construction procurement specifications for packaging waste reduction can drastically impact the waste management strategy and is of utmost importance to remaining economical, efficient and compliant.

Effective, efficient and economical procurement

The procurement of materials and products can impact overall project costs exponentially and is a fantastic opportunity to make sustainable choices. Below are some examples of procurement types and how they promote sustainable building practices which, when incorporated into the waste management strategy promote efficiency, affordability and compliance with current building legislation.

Types of procurement and how they promote sustainable building practices

|

Procurement method |

Example of Method Promoting Sustainability |

|

Effective procurement – goals of the procurement method are met. |

Sustainability is promoted by the procurement of building materials and products that could be recycled. Waste material produced by the project can be recycled instead of just being disposed of. |

|

Efficient procurement - the unnecessary expense is avoided |

By checking the current inventory, a procurement officer can find leftover materials that could still be used and avoided procuring materials that might end up being unused. Sustainability was promoted by avoiding unnecessary procurement. |

|

Economical procurement |

The procurement officer decides that the more expensive products are worth the added expense because they come from environmentally friendly and ethical suppliers. The monetary value of the building products was weighed against their environmental value. Sustainability was promoted by supporting suppliers with ethical and green practices. This promotion will encourage suppliers to continue using these practices. |

The use of effective, efficient and economical procurement of materials and products was predominately used to exemplify how to calculate costs, potential savings and advantages of a waste management strategy and negotiate with the client. As you venture further through the topic, additional procurement and waste management strategies will be addressed.

Procurement specifications for packaging waste reduction

Now you are aware of how to establish effective, efficient and economical procurement it is pertinent to the waste management strategy you enforce these procurement specifications for packaging waste reduction. Working in the construction procurement specifications for packaging waste reduction can drastically impact the waste management strategy and is of utmost importance to remaining economical, efficient and compliant.

There are many reasons for why the packaging waste should be reduced, provided below are the most common benefits:

- Energy consumption will be reduced when taking in raw materials instead of processed or manufactured into packaging.

- Air pollution will be reduced as the pollutant that are released into the air such as dust and carcinogenic substances are reduced. These pollutants are a result of on-site packaging waste are not disposed of appropriately.

- Reduced risk of having hazardous components in landfills due to packaging and plastics' degradation within the landfill site.

In general, the considerations you need to make to minimise packaging waste include;

- packaging and packaging waste types found on construction sites;

- legislation in Australia for packaging waste;

- measures to eliminate, reduce, re-use and recycle packaging waste that are practical and economical;

- how to conduct waste segregation;

- issues encountered by management regarding minimising packaging waste

- tools, information, advice and resources to help improve packaging waste management at the construction site;

A Construction Packaging Waste Estimator will help you save money by minimising packaging waste on your site.

When looking at procurement specifications for packaging waste reduction, the whole of the supply chain needs to be incorporated, particularly suppliers. The Australian Packaging Covenant (APC) is an Australian regulatory framework under the National Environment Protection (Used Packaging Materials) Measure 2011 (NEPM) that sets out how governments and businesses manage environmental impacts of packaging. The Australian Packaging Covenant Organisation (APCO) manages and governs the Covenant.

This Australian regulator aims to reduce the environmental impacts of consumer packaging and has set a framework for enterprises wanting to reduce packaging waste throughout the supply chain. Primarily, locating suppliers who are part of the APC framework would provide optimum results due to shared objectives of reducing packaged waste. An alternative is to use the APC framework to guide procurement specifications concerning reducing packaged waste.

APCO sustainable packaging principles can guide the review of existing and new packaging to identify opportunities for improvement. Requiring the suppliers to abide by sustainable packaging principles is one of the best ways to manage procurement specifications for packaging waste reduction.

The 10 Principles to be considered in the design and procurement of packaging to improve sustainability are:

- Design for recovery

- Optimise material efficiency

- Design to reduce product waste

- Eliminate hazardous materials

- Use recycled materials

- Use renewable materials

- Design to minimise litter

- Design for transport efficiency

- Design for accessibility

- Provide consumer information on sustainability

In the waste management strategy, you need to consider the methods of reducing packaging waste on a building and construction site along with the environmental benefits of reducing packaging waste. Importantly, company purchasing specifications should be concise and leave little room for fault.

Engaging with environmentally responsible suppliers

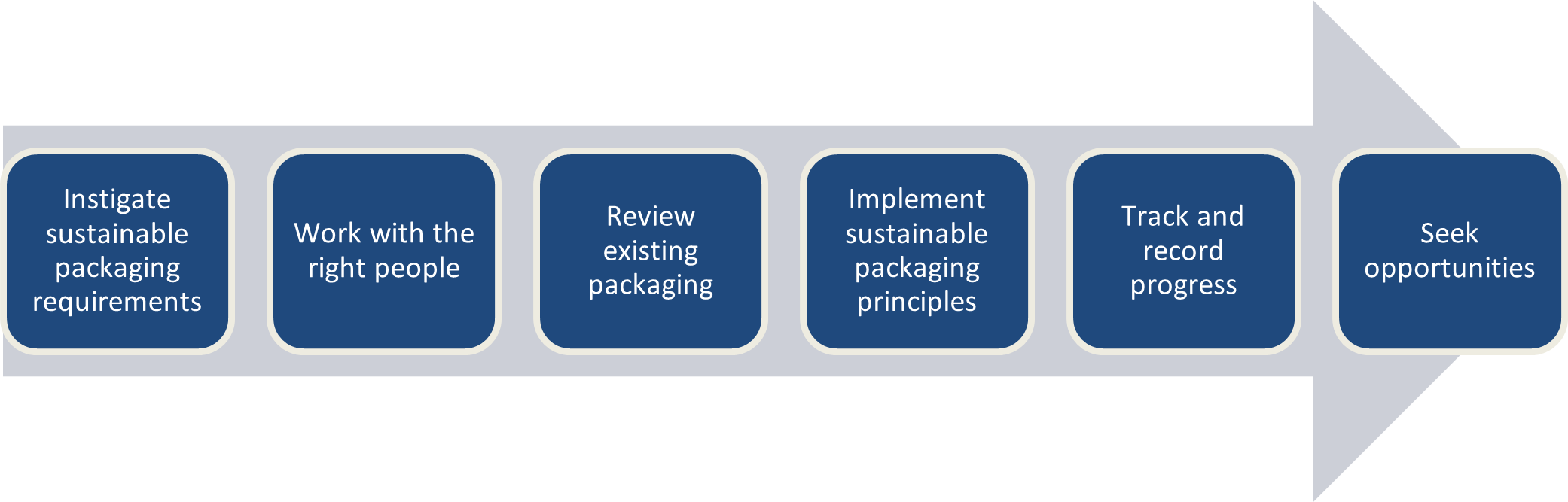

As discussed, locating suppliers who are part of the APC framework would provide optimum results due to shared objectives of reducing packaged waste. An additional option is to use the APC framework to guide procurement specifications concerning reducing packaged waste. Importantly, engaging with environmentally responsible suppliers can be a simple objective to meet, provided the whole organisation is included, and strict guidelines can be followed. One process that can help engage environmentally responsible suppliers has been demonstrated below. This process can be a useful tool for the waste management strategy to incorporate.

Step 1: instigate sustainable packaging requirements

- Advocate the cost benefits of waste minimisation and recycling to clients and tenders

- Notify tenders with recycling, waste management and waste minimisation strategies

- Communicate by answering questions and alleviating concerns (costs)

- Induce workplace cooperation to achieve waste minimisation objectives

Step 2: work with the right people

- Understand who can influence packaging decisions

- Develop a statement of commitment

- Organise a planning meeting

- Encourage collaboration and engagement with suppliers.

- Assign responsibilities

Step 3: Review existing packaging

- Complete a review of your existing packaging with suppliers to better understand the environmental impact of your existing packaging and potential opportunities for improvement

Step 4: Implement the Sustainable Packaging Principles

- Consider opportunities to integrate sustainable design criteria into new product development processes

Step 5: Track and report progress

- All aspects of SPGs implementation must be documented. Decisions, discussions and the underlying evidence for those decisions must be retained on file for independent auditing and continuing sustainability improvement

Step 6: Seek opportunities for continual improvement

- Implement regular reviews and checks

- Seek input and feedback from suppliers

When you are developing procurement specifications that seek to minimise packaging waste remember the importance of effective, efficient and economical procurement, incorporate specifications for reducing packaging waste and engage with environmentally responsible suppliers who share the same values and promote sustainable building.

When engaging with environmentally responsible suppliers look for and ensure that the supplier's processes do the following:

- Minimise their negative environmental impact

- Promote sustainability

- Follow workplace procedures and workplace safety requirements