The overarching aim of WHS legislation is to minimise harm to all who enter a workplace. Key to this objective is establishing procedures to identify and control hazards and risks. In this chapter we will explore, your responsibilities to respond and to report workplace incidents as well as common hazards in the workplace. We will identify a range of safety signage, ways to identify, control and manage risks and the process for monitoring and reviewing risk controls.

By the end of this topic, you will understand:

- The difference between a hazard and a risk

- Common workplace hazards

- A range of safety signage

- Hazards in the workplace

- How to conduct and record a risk assessment.

A hazard is anything that has the potential to be harmful. Harm may include disease, injury or damage to the environment, equipment or property. A hazard can be:

- An individual physical thing (for example, a sharps container without a lid)

- A situation (for example, the need to lift a heavy client who has fallen)

- Multiple factors or circumstances (for example, a colleague has gone home sick and you are left to work a shift on your own).

Hazard vs Risk

A risk is a possibility that harm can occur when exposed to a hazard. Risk considers the likelihood of a hazard to cause injury and the consequences.

Examples

- An unlocked chemical cupboard is a hazard. A risk is that an unauthorised person may access the chemicals and cause them injury or harm

- Working a double shift is a hazard. A risk is that fatigue may cause mistakes or lapses of attention

- Exposure to biological products is a hazard. A risk is that infection may result.

Report Issues, Incidents and Injuries

All workers have a responsibility under WHS laws to report hazards in the workplace (Safe Work, n.d. [D]). This means that if you notice that a piece of equipment is damaged, a colleague is not following procedures or a task that is being performed is unsafe, then you have a legal duty to report that hazard in line with your organisation’s policies and procedures. This requirement by law extends to near misses; that is, where something could have happened, but did not. Near misses are important opportunities for organisations to learn how to manage and improve their worker safety.

As a worker, you must:

- Be aware of your organisation’s procedures for reporting accidents and incidents in the workplace (these may include completing an incident report, placing an entry in a hazard log or sending an email to your WHS representative or committee)

- Report all accidents and incidents to your immediate supervisor as soon as possible

- Maintain the privacy and confidentiality of personal and health information of an injured worker or person in accordance with the requirements with the privacy legislation within your state or territory

- Participate in risk management consultation processes and incident investigations as required

When completing written reports or documentation, it is important to use clear language, legible handwriting and ensure that the documents are submitted in line with procedures. This will help to ensure that prompt action is taken to address the hazard or risk.

Common Workplace Hazards

Workplace hazards are typically divided into physical hazards, chemical hazards (Safe Work Australia, n.d. [B]) and behavioural hazards. See the types of hazards for each of these groups in the table below:

Physical Hazards

- Lifting or maneuvering heavy equipment or people

- Damaged or poorly designed equipment and furniture

- Clutter and congestion

- Exposure to biological products or waste

Chemical Hazards

- Gas or vapors from poor ventilation

- Fumes

- Dust

- Liquid spill

Behavioural Hazards

- Inexperience or inadequate training

- Not following procedures

- Poor health or stress

- Poor employee relationships and harassment

- Inadequate rest from repetitive action

Hazardous Manual Tasks

Hazardous manual tasks are any tasks that involve repeated or sustained force, high or sudden force, repetitive movement, sustained or awkward posture or exposure to vibration. Hazardous manual tasks present a high risk of causing damage to the musculoskeletal system (comprised of muscles, ligaments, bones, tendons and joints). Some examples of hazardous manual tasks are outlined in the table below:

|

Repeated or sustained force |

|

|---|---|

|

High or sudden force |

|

|

Repetitive movement |

|

|

Sustained or awkward posture |

|

|

Exposure to vibration |

|

Injuries from hazardous manual tasks comprise of 90% of all worker's compensation claims in Australia (Safe Work Australia, n.d. [C]). Since there is such a high incidence of these types of injuries, they must form a part of any hazard evaluation in a workplace.

Website

Safe Work Australia’s model code of practice: Hazardous manual tasks (Safe Work Australia, n.d. [D]) explains how to identify hazardous manual tasks and minimise the risks associated with them. You can access the model code of practice at Safe Work Australia’s website.

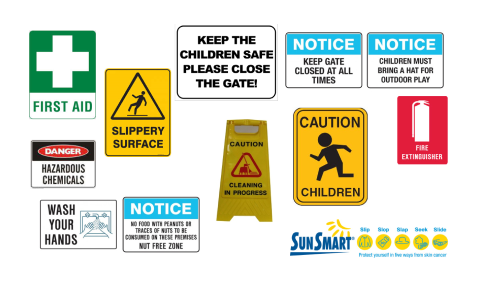

Workplaces display a range of signs in order to protect workers and visitors from harm. It is essential that you comply with such signs at all times. These may include signs for:

- Exits and emergency exits, fire escapes and the location of fire extinguishers

- HAZCHEM (i.e. a warning sign) to show the location and classification of dangerous materials such as chemicals, compressed gasses or explosives

- Specific work areas that require those who enter to hold specific certification or approval (for example, confined spaces)

- Areas of high voltage (for example, electrical substations)

- Areas that require PPE to be worn

The following 6-minute video demonstrates common incidents in early childhood education and care settings:

In an early childhood education and care environment, signage may also include the following:

- Emergency Exits

- First Aid Kit locations

- Emergency exit route

- Chemical cupboard/ area

- Wet floor signage for cleaning

- Service signs like staff room, kitchen, office, parent's room, toilets and other amenities

- Signs in the kitchen

- Safety signs like emergency procedures, child protection procedures and service-specific policies.

RESOURCE

Click here to access a list of common safety signs and their meaning.

Due to the significant risk of injury hazards present to yourself and others, you must be aware of and follow safety signage in line with your workplace procedures. Make sure that you check with the services policies and procedures on what your responsibilities are.

168 Education and care service must have policies and procedures

- (1) The approved provider of an education and care service must ensure that the service has in place policies and procedures in relation to the matters set out in subregulation

- (2). Penalty: $1000. Note— These may include policies and procedures prepared by the approved provider in accordance with an education law of the participating jurisdiction.

- (2) Policies and procedures are required in relation to the following—

- (a) health and safety, including matters relating to—

- (i) nutrition, food and beverages, dietary requirements; and

- (ii) sun protection; and

- (iii) water safety, including safety during any water-based activities; and

- (iv) the administration of first aid; and

- (v) sleep and rest for children;

- (b) incident, injury, trauma and illness procedures complying with regulation 85;

- (c) dealing with infectious diseases, including procedures complying with regulation 88;

- (d) dealing with medical conditions in children, including the matters set out in regulation 90;

- (e) emergency and evacuation, including the matters set out in regulation 97;

- (f) delivery of children to, and collection of children from, education and care service premises, including procedures complying with regulation 99;

- (g) excursions, including procedures complying with regulations 100 to 102;

- (ga) if the service transports or arranges transportation of children other than as part of excursions, transportation including procedures complying with

Division 7 of Part 4.2 of Chapter 4; (h) providing a child safe environment;

- (i) staffing, including—

- (i) a code of conduct for staff members; and

- (ii) determining the responsible person present at the service; and

- (iii) the participation of volunteers and students on practicum placements;

- (j) interactions with children, including the matters set out in regulations 155 and 156;

- (k) enrolment and orientation;

- (l) governance and management of the service, including confidentiality of records;

- (m) the acceptance and refusal of authorisations; (n) payment of fees and provision of a statement of fees charged by the education and care service;

- (o) dealing with complaints.

Risk management procedures typically follow a four-step approach:

- Identify hazards

- Assess risks

- Control risks

- Evaluate control measures

Safe Work Australia, n.d. [E]

You can refer to the following list for some information on each of these steps before we discuss them in more detail:

- Identify Hazards

Hazards may be identified via workplace inspections, while completing a specific task or using a piece of equipment, or as part of an incident investigation or review. - Assess Risks

Identify the likelihood and impact should the risk presented by the hazard eventuate. A risk matrix can be a useful tool in this step. - Control Risks

Determine how the risks are to be controlled. The hierarchy of risk is a systematic approach to determining the most appropriate risk management approach. - Evaluate Control Measures

Review the risk controls implemented to determine their effectiveness. This can be done by gathering staff feedback, evaluating incident reports and staff absentee rates, and evaluating productivity.

Step 1: Identify Hazards

Early childhood services will have procedures in place to manage workplace risk. A systematic approach to risk management improves safety and ensures that workers are aware of their role's importance in risk management. Management commitment is essential in this respect. WHS is seen as an integral part of business operations rather than a compliance issue.

A proactive attitude towards hazard and risk management will:

- Minimise the number and severity of workplace injuries and illness as well as the costs associated with these

- Promote a positive culture of health and wellbeing in the workplace

- Promote innovation and continuous improvement

As we saw earlier, regular workplace inspections form part of the hazard identification processes. Other ways in which hazards may be identified include:

- Inspecting equipment or tools prior to use

- Debriefing or evaluating processes following events or incidents in the workplace

- Observing how colleagues or others perform tasks or use equipment

- Evaluating your personal levels of stress or fatigue

The following 5-minute video explains how to maintain safety and security of children:

Identify hazards by:

- Observing

- inspecting

- investigating

- communicating, and

- consulting with others.

Making a record of the hazards identified. A hazard is a source or situation with the potential for harm in terms of human injury or ill health, damage to property, the environment, or a combination of these. Specific hazards may include

Physical:

- Moving parts of machinery

- Manual handling

- Sharps

- Noise

- Extreme weather or temperatures

Chemical and biological:

- Medicines and waste

- Bodily fluids

- Insects and animal waste

- Combustibles and hazardous air.

Ergonomic:

- Work posture

- Repetitive work, and

- Manual handling

Psychosocial:

- Stress

- Fatigue

- Bullying

- Relationships

- Workloads and Role clarification.

Hazard identification is a process of identifying sources of harm and includes:

- Conducting a site safety audit

- Completion of a safety checklist

- Inspections of the workplace or venue / space

- Observation of daily activities

- Investigation of accidents and incidents, including near misses

- Review of injury or illness registers

- Environmental monitoring of workplace or venue / space

- Investigation of staff complaints concerns

- Review of staff feedback.

- Before new forms of work and organisation of work are implemented

- Before changes are made to workplace, equipment, work processes or work arrangements

- As part of planning major tasks or activities, such as equipment shutdowns

- Following an incident report

- When new knowledge becomes available

- At regular intervals during normal operations

- Prior to disposal of equipment, or materials.

In this first step you will need to talk with the WHS representative as well as other people who have or will use the environment. It is important to know the hazards of your industry as well as the hazards of the immediate work environment.

Step 2: Assess Risks

Assessing risks involves evaluating how big a risk is and what the potential impact would be if it were to occur. Impacts include harm to workers and others (and the number of people potentially harmed), as well as financial, productivity and legal ramifications. This process helps workplaces determine priorities for risk management and to evaluate the time, money and effort required to manage the risk.

Risk assessment can be undertaken using a risk management matrix. The matrix plots the probability of a risk occurring against the severity of the consequences if it did occur to reveal a risk rating of low, medium, high or extremely high. Identify the likelihood and impact should the risk presented by the hazard eventuate.

A risk matrix can be a useful tool in this step.

You should always:

- Assess and prioritise the risks.

- Deal with the highest priority risks first and

- Deal with fewer risks or least significant risks lasts.

Once hazards are identified in the working environment you will need to assess the risk of something happening because of the hazard. Risk in relation to any hazard means the probability and consequences of injury, illness or damage resulting from exposure to the hazard.

Key questions for assessing risk:

- How likely is the injury to happen?

- Has it happened before?

- Has someone been injured? If so, how badly?

- What is currently in place to prevent it from happening and how successful is it?

- How often will you, the client or other person be exposed to the hazard?

It is important to talk with other people who may understand the hazard or experiences with the hazard, to answer the questions about risk assessment. Make sure you record your risk assessment according to your organisation’s policy. The purpose of risk assessment is to prioritise the hazards for attention. Hazards can then be placed into one of the following categories:

- It is desirable to address the hazard

- The hazard must be addressed before workers can work

- The hazard must be dealt with before the worker can enter the workplace.

Step 3: Decide on measures to control the risks by:

- Eliminating the risk

- If elimination of the risk is not possible, select these control measures in the following order of preference:

- Substitution

- Isolation (not administrative)

- Minimisation by engineering means

- Application of administrative measures

- Use of Personal Protective Equipment (PPE).

Determine how the risks are to be controlled. The hierarchy of risk is a systematic approach to determining the most appropriate risk management approach.

Step 4: Control the risk

Risk control should always aim to eliminate a risk so far as is reasonably practicable (Safe Work Australia, n.d. [F]). The risk assessment process and use of the matrix will help determine what should be considered reasonable for controlling any specific hazard or risk.

In many situations the way you control the risk will require more than one action. The diagram below outlines what is known as the Hierarchy of Control. It describes the preferred options for controlling risks. As you work down the list, the controls become less reliable and harder to maintain and ensure they work. Risk control should always aim to eliminate a risk so far as is reasonably practicable (Safe Work Australia, n.d. [F]). The risk assessment process and use of the matrix will help determine what should be considered reasonable for controlling any specific hazard or risk.

Hierarchy of Control

The Hierarchy of Control is a list of control measures that can be used to eliminate or minimise exposure to the hazard. The hierarchy of control must be used in seeking to eliminate or minimise workplace risks.

Evaluate Control Measures

Review the risk controls implemented to determine their effectiveness. This can be done by gathering staff feedback, evaluating incident reports and staff absentee rates, and evaluating productivity.

The Education and Care Services National Law requires you to ‘ensure that every reasonable precaution is taken to protect children… from harm and from any hazard likely to cause injury’ (Section 167). Taking precautions involves carrying out risk assessments within your service to assess the risks and plan how to manage them.

Services may use:

Risk assessments

Examples of risk assessments:

- A broken toy – you

- observe the hazard as the children are playing and the toy is broken.

- On the spot you do your assessment as the toy is now a risk to the children.

- You manage the risk by taking the toy away and eliminating the risk.

- Your evaluation is the hazard is removed.

- You may look at repairing the toy or replacing the toy and your review would take place when this happens.

- Nappy changing procedure – you identify the potential risk of lifting young children to the change mat throughout the day. You assess it as a high risk due to the frequency and consequences. As the nappy changing cannot be eliminated it is managed with educators:

- undertaking manual handling training

- sharing the nappy changing throughout the day

- installing a step ladder to reduce the lifting within the routine.

On evaluation this has reduced the risk of injury to educators. Review and monitor to ensure the control measures are applied consistently.

Check out ACECQA for their educational template on risk assessments.

Supervision Plans

An excursion to the park – once you have your idea, use an excursion risk management plan (such as the template on the ACECQA website) to organise and do a risk assessment. Crossing the street to get to the park and the lack of footpath are identified and assessed as a high risk. This is managed with a plan to have a higher ratio of educators attend, an alternate route via traffic lights for the crossing and a footpath, and careful orientation and expectations around behaviour with children and educators. This is evaluated as an acceptable risk and during the excursion it is monitored and reviewed for future excursions.

The next video is a short video explaining the fundermentals of activer supervision.

Watch this next video explaining active supervision in the outdoor environment.

Policies and Procedures

Key Things to Consider about Work Health and Safety

When thinking about work health and safety, there are many considerations, including:

The legal requirements in your jurisdiction:

- Check which Act, Regulations and Codes of Conduct/Guidance notes apply in your state or territory. See the Resources section for relevant contacts in each jurisdiction.

- You may be required to have a staff Work Health and Safety Representative.

Your existing work health and safety policies and procedures:

- A review is an essential starting point. For ideas on how to review your policies see How to Develop and Update Policies Successfully (without the stress).

- Implementation and monitoring of policies and procedures.

All services should have a policy on work health and safety, and on matters that affect children’s safety. Some other work health and safety matters you could consider are:

- Emergency planning

- First aid ü Hazard identification & control (Risk Assessment & Hazard Register)

- Electrical safety

- Ladder safety & working at heights (fall prevention policy & procedures)

- Personal safety (aggression from clients, working alone)

- Plant safety (machinery and equipment)

- Slips, trips and falls

Some or all these matters may be relevant in your workplace. Refer to How to Develop and Update Policies Successfully (without the stress) for ideas and Policies for the NQF: Policies in Practice on the PSC Allliance website (www. pscalliance.org.au). The sample policies provided are intended as a guide only for individual service policy development.

Safety audits

A safety audit identifies areas that can cause problems or items that should be checked to satisfy yourself or others that they cannot cause a problem in the future. A safety audit helps managers / supervisors identify areas they may otherwise overlook. A safety audit involves checking all aspects of the organisation, including policies, equipment, staff training and the general environment.

Safety audits are a tool that you can use to help maintain a safe, efficient work area; and should be welcomed by staff as an occurrence that will improve their working environment, and personal wellbeing.

Sample safety audit checklist:

| Items | Yes/No | Comment |

|---|---|---|

| Kitchen | ||

|

Floor satisfactory:

|

||

| Table and chairs stable | ||

| Dry power fire extinguisher (at least 5.5kg) | ||

| Fire blanket | ||

| Staff trained to use fire extinguisher and blanket | ||

| No curtains overheat surfaces | ||

|

Electrical leads in good order Electrical cords keep to minimum length |

||

| Fire alarm tested | ||

| Power points in adequate positions | ||

| Microwave in adequate positions | ||

| Other items | ||

Download a copy of the safety checklist.

Case study

Alice Reports a Hazard

Alice has noticed that the empty fruit and vegetable boxes often remain stacked in the kitchen for several hours. She knows it is her role to remove these boxes, but she is unable to do this as it would mean leaving the children unattended. Alice has also noticed that sometimes the fruit and vegetable company do not collect the empty boxes for days at a time. This means that the area outside the back door, leading into a rear laneway, becomes blocked, effectively blocking off an emergency exit.

Alice knows that it is her responsibility to report and act upon hazards when she identifies them. She reports the incident to her team leader and completes the hazard form as defined in Green Hills’ risk management policy.

Reasonably Practicable

Health and Safety Representatives (HSRs) play an important role in the partnership between staff and management, by ensuring that all employees have the opportunity to participate in decisions affecting their health and safety at work. HSRs have wide-ranging powers to promote the health and safety of employees in their designated work group. Broadly these powers are:

- Inspect the workplace

- Investigate accidents and dangerous occurrences

- Investigate risk of serious injury to, or harm to the health of, any person

- Keep informed on current workplace health and safety information

- Report hazards to the employer

- Refer matters to the occupational safety and health committee (if present in your workplace)

- Consult and co-operate with management

- Liaise with staff

Issues you are expected to raise with HSR (or other designated person) include but are not limited to:

- Specific workplace hazards

- Missing or incorrect safety signage

- Incomplete, or incorrect procedures

- Broken equipment and furniture

- Broken or faulty safety equipment

- Damaged or missing Personal Protective Equipment (PPE)

- Potential emergency situations

- Potential dangerous goods and equipment

- Exposure to unsafe equipment, products, contaminants

- Reoccurring accidents or incidents

- Results of drills.

The WHS laws state that an employer, also known as a ‘person conducting a business or undertaking’ (PCBU), has a requirement to do whatever is reasonably practicable to eliminate or minimise health and safety risks. The Work Health and Safety Act 2011 defines reasonably practicable as an evaluation of the following:

- The likelihood of the hazard occurring

- The degree of harm that may result

- Knowledge about the hazard or risk and ways of managing or eliminating it

- The availability and suitability of risk reduction or elimination methods

- Whether the cost of eliminating the risk is proportionate to its occurrence

- Safe Work Australia, n.d. [E]

A risk that has been evaluated as having an extremely high-risk rating will warrant a greater investment in time, money and effort as opposed to one that has a lower chance of risk. Consider the following example:

- A child-care centre has undertaken a workplace inspection and identified the following risks:

- There is a tree in the facility with lowhanging branches. It is considered that staff members could injure themselves if they walked into a branch while supervising children at play.

- The medicine cabinet is mounted on a wall in the staff room. If damage were to occur to the wall, the cabinet could fall, injuring a staff member.

The first risk is assessed as being possible, with a moderate impact should it occur, which results in a risk rating of a high 12. The second risk is assessed as improbable, with a moderate impact should it occur, which results in a risk rating of a low 3.

Consultation with Stakeholder to Risk

Employers, usually referred to as PCBUs, have a duty to consult with all stakeholders who may be exposed to a risk. This means that anyone who is impacted by that risk (or has the potential to be impacted) must be given the opportunity to help shape how that risk is to be managed. Not only is this a legal requirement, it also makes good practical sense in that those who are most closely involved in the situation presenting the risk may well also be best positioned to manage the risk in a practical manner.

Consultation is typically undertaken via toolbox talks, formal meetings or via email (see section 2.3). The most suitable method will vary according to the location of stakeholders and the nature of risk to be addressed.

Participate in meetings

When workers participate in safety meetings and contribute to developing new procedures, they feel a greater sense of ownership and are more likely to adhere to the correct protocols. All workers must be involved in the development and improvement of the WHS programs; their insight and perspective can be very useful. Participate and contribute by:

- Reviewing the WHS policies and procedures

- Attending regular WHS meetings

- Familiarising yourself with everyone’s WHS responsibilities of managers.

- Modelling safe and healthy behaviours for co-workers

- Reporting WHS issues in a timely manner.

- Identifying workplace hazards and risks and raising them with HSR

- Reviewing and evaluating safety initiatives

- Volunteering to conduct safety audits and inspections

- Volunteering to be a HSR

- Participating in the development of workplace policies and procedures at staff meetings

- Reflecting on how things are working and what can be changed

- Conducting brainstorming sessions with co-workers about how to improve your immediate work area

- Participating in regular inspections to evaluate safety in your work area

- Ensuring posters and brochures are up to date with most current expectations

- Bringing any outstanding or new issues to the attention of the supervisor / manager

Your organisation should provide opportunities for you to participate in and contribute to workplace safety meetings, inspections, as well as consultative activities by:

- Holding training for staff to ensure policies are understood and followed and that all are up to date on proper certification (first aid, CPR, and other workplace safety certificates that may be required)

- Training staff on issues that pertain to your work area specifically (lifting, food handling, etc.)

- Inviting staff to contribute to daily, weekly, monthly and annual lists of things to be considered

- Educating staff about common and uncommon illnesses.

- Ensuring that they know when to stay home and when it is ok to come to work.

- Asking staff about their expectations or concerns regarding safety procedures and implementing changes to policies

- Ensuring that all policies are in accordance with state or federal standards.

Hierarchy of Control

The hierarchy of control process can be used for evaluating all risks. Under WHS legislation, a hierarchy of control process must be used for managing certain types of risks.

The hierarchy lists methods of managing a risk shown from that which is most effective (elimination) through to that which is least effective (using PPE).

The aim must always be to eliminate risks so far as reasonably practicable. This can only be achieved by eliminating the hazard. What is considered reasonably practicable will vary according to the nature of the risk and the risk rating. If you revisit the example of the tree with low-hanging branches at a child-care centre, total elimination of the risk would be to remove the tree. Actions like trimming the low-hanging branches, however, may be considered appropriate. In the instance of the medicine cabinet on the wall at the child-care centre, the risk could be removed by reinforcing the wall or installing a standalone cabinet; both of these solutions may be considered as reasonably practicable given the low risk.

Evaluate Risk Controls

A risk management plan should include performance measures that define what a successful risk control outcome will look like. This may include:

Completely eliminating the risk:

Example

If the risk associated with cleaning upper-storey windows is considered to be unacceptable, choosing to either not clean the windows or outsourcing the task to a window-cleaning organisation will eliminate the risk.

Reducing the risk to an acceptable level:

Example

Arranging for staff to undertake appropriate training and providing safety equipment and PPE may reduce the risk associated with cleaning high-level windows to an acceptable level.

A risk management plan should define how and when the evaluation of the risk controls will occur. Deciding on a timeframe will vary according to the nature of the risks being controlled. For example, risk controls implemented to manage a one-off event (for example, a companywide off-site planning day) can be evaluated shortly after that event. In contrast, evaluating risk controls associated with the introduction of a new piece of equipment may require a longer evaluation timeframe to ensure there is an adequate measure of the success of the controls.

Sources of Evaluation Information

Typically, evaluation will rely on information from a variety of sources. The selection of evaluation methods will need to consider the type of information required and how that information can be collected. Anyone who was initially involved in a consultation to address identified risks should always be involved in the review process.

Common evaluation methods are explored in the table below:

|

EmployeeFeedback |

|

|---|---|

|

OrganisationalData |

|

|

Observation |

|

Case Study

Evaluation of Hazard Controls

Alice met with her team leader, kitchen staff and a representative from the fruit and vegetable supplier to determine how the risk presented by the empty fruit and vegetable boxes blocking the rear laneway could be addressed. It was determined that the following controls would be implemented:

- The kitchen staff would flatten the boxes once they had been emptied

- Alice would place the flattened boxes against the wall in the laneway so that the exit was not blocked

- The fruit and vegetable company would ensure their delivery team was instructed to collect the empty boxes every day

Document and Report Risk Management Outcomes

Keeping records of incidents and risk management processes is a legal requirement. It also ensures that your organisation is able to review the effectiveness of the risk management controls it implements.

Your organisation should have specific processes for documenting risk management processes such as the use of specific forms or templates, WHS reporting requirements and storage or display of documents and reports.

Risk management documentation should include:

- The nature of hazards identified and the identification process followed

- A description of how risk management decisions were made

- Who was involved in the risk-management process

- How risk-management controls were implemented (for example, staff training, procedure modification and changes to plant and equipment)

- Implementation processes such as training records

- Review processes including review methods and the timeframe for review

Throughout this module, we have spoken about Work Health and Safety and associating the risks around being in a centre-based environment. Another aspect we are going to explore is what happens when children need to leave the service.

Children are sometimes transported by, or on transport arranged by, children’s education and care services. Service providers, nominated supervisors and educators need to take specific steps to ensure the health, safety and wellbeing of children.

Transportation may present additional risks to children depending on how it occurs and how transition between a vehicle and an education and care service premises or other location is managed. These risks apply equally to single trips or during periods of regular transportation.

Transportation of Children

Children may need to leave the service for reasons like:

- OOSH- School drop off or pick up

- Children being dropped off or picked up from home

- Community services

- FDC- School drop off or pick up

Excursions

- Excursions into the community (walking)

- Excursions into the community (transportation)

- OOSH- Vacation Care

When preparing/ planning for such experiences, there are some crucial steps that need to be taken to ensure the effective health and safety of the children have been taken into consideration before children venture out of the service. One of the requirements is to conduct a risk assessment. a risk assessment is required by the National Law and Regulations.

02 Authorisation for excursions

- The approved provider of an education and care service must ensure that a child being educated and cared for by the service is not taken outside the education and care service premises on an excursion unless written authorisation has been provided under subregulation

- A nominated supervisor of an education and care service must ensure that a child being educated and cared for by the service is not taken outside the education and care service premises on an excursion unless written authorisation has been provided under subregulation (4). Penalty: $1000.

- A family day care educator must ensure that a child who is being educated and cared for by the educator as part of a family day care service is not taken outside the residence or approved family day care venue on an excursion unless written authorisation has been provided under subregulation

- Penalty: $1000.

- (4) The authorisation must be given by a parent or other person named in the child’s enrolment record as having authority, given by a parent, to authorise the taking of the child outside the education and care sevice premises by an educator and must state—

- (a) the child’s name; and

- (b) the reason the child is to be taken outside the premises; and

- (c) if the authorisation is for a regular outing, a description of when the child is to be taken on the regular outings; and

- (ca) if the authorisation is for an excursion that is not a regular outing, the date the child is to be taken on the excursion; and

- (d) a description of the proposed destination for the excursion; and

- (e) if the excursion involves transporting children—

- (i) the means of transport; and

- (ii) any requirements for seatbelts or safety restraints under a law of each jurisdiction in which the children are being transported; and

- (f) the proposed activities to be undertaken by the child during the excursion; and

- (g) the period the child will be away from the premises; and

- (h) the anticipated number of children likely to be attending the excursion; and

- (i) the anticipated ratio of educators attending the excursion to the anticipated number of children attending the excursion; and

- (j) the anticipated number of staff members and any other adults who will accompany and supervise the children on the excursion; and

- (k) that a risk assessment has been prepared and is available at the service.

- If the excursion is a regular outing, the authorisation is only required to be obtained once in a 12 month period.

Considerations include

- Hazards

- Potential Risks

- Issues that may arise on the outing

- Route of transportation

- Procedures for a missing child

- Procedures for a child being injured

- Procedures if an emergency situation was to arise

For more information check out the ACECQA fact sheet Safe Transportation of Children.

As well check out the regulations relating to transportation with children

Use the following questions to check your knowledge. You can check your answers by clicking on the 'Answer' button.

Q1. Describe the difference between a hazard and a risk.

A risk is the possibility that harm can occur when exposed to a hazard; risk considers the likelihood of a hazard to cause injury and the consequences.

Q2. Provide an example of a physical, behavioural and chemical hazard in your industry or workplace.

- Physical:

- Lifting or maneuvering heavy equipment or people

- Damaged or poorly designed equipment and furniture

- Clutter and congestion

- Exposure to biological products or waste

- Chemical:

- Gas or vapors from poor ventilation

- Fumes

- Dust

- Liquid spill

- Behavioural:

- Inexperience or inadequate training

- Not following procedures

- Poor health or stress

- Poor employee relationships and harassment

- Inadequate rest from repetitive action

Q3. A risk management matrix plots likelihood against consequence to determine a risk rating.

Is this statement true or false?

Q4. What is meant by ‘a proactive approach to risk management?’

Q5. Hazardous manual tasks comprise what percentage of workers’ compensation claims in Australia?

- 90%

- 40%

- 30%

- 55%