Step 2- Erecting the formwork.

This is the second step is to erect the formwork. Each step in this process has been broken down for you.

The stages of erecting the formwork are:

- Preparing the substrate

- Reviewing and confirming the formwork design

- Erecting the formwork

- Installing the vapour barrier.

The substrate is the ground that the concrete sits in (or on). The substrate is the first layer, usually containing natural elements such as soil and rock. The purpose of having the substrate is to help prevent water from seeping into the underlying layers causing damage. Without the substrate layer, any extra moisture may cause cracking and effect the integrity of the build.1 Concrete needs an even, level, firm base to sit on so there is often some work that you need to do to the ground before you can erect your formwork. This may include:

- removing grass, weeds and plants

- removing topsoil

- excavating earth to the required depth

- creating a level surface

- clearing tree roots and other obstructions

- filling and compacting any soft areas.

In some cases, a layer of crushed rock or road base is added to help even out the substrate. Occasionally, drainage might be added at this stage.

The following video demonstrates how a concrete slab is prepared on a site. Please be advised, at the point of preparation in this video, the area itself has already been prepared.

Before you start pouring concrete, you need to ensure you have checked and confirmed the formwork design is correct. Once the concrete has been poured, there is not a lot of room for repair, so if the formwork is not right, the concrete is not likely to be right either. Before moving on to erect the formwork, you should take some time to review the plans, specs, and work instructions/work order. You might like to ask yourself the following questions:

- Am I working from the most recent version of the plans, specs and drawings?

- Have I correctly interpreted the plans?

- Have I confirmed the thickness of the slab?

- Are my measurements and calculations, correct?

- Have I confirmed that my slab (or another concrete project) will be located accurately on the site?

- Do I have the materials that I need?

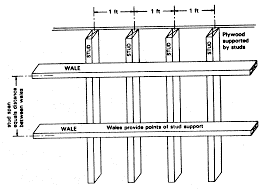

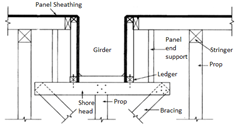

The following image sliders provide some examples of what formwork drawings look like.

Now that you have prepared the substrate and confirmed the formwork design, it is time to erect the formwork. There are some important tips to remember when installing formwork.

- Formwork must be strong enough to support the concrete which will sit inside it without moving, flexing, bending, or bowing.

- Pegs should be installed approximately every 800 mm. Additional pegs are installed in each corner.

- Pegs should be set below the top edge of the formwork so that they do not interfere with screeding.

- Check for square and level as you work and then again at the end.

- Edge boards should be clean and free of dust etc.

- A light layer of form oil should be applied to the inside of all boards. Form oil helps to stop the concrete from sticking to the boards.

- Formwork can be left in place to help the concrete cure.

Watch the following video from Buildsum for a step-by-step guide to erecting formwork.

A vapour barrier is a mandatory requirement stipulated by the National Construction Code (NCC). To meet the NCC requirements, the vapour barrier needs to be nominal 0.2mm thick polyethylene film, be medium impact resistant and be branded continuously “AS 2870 Concrete underlay, 0.2mm Medium impact resistance.” 7

The vapour barrier is a sheet (or sheets) of plastic installed under a slab (before the reinforcement materials). Vapour barriers stop moisture from moving from the ground into the slab and into a house or other building. They can also and inhibit mould growth and concrete cancer.

When installing a vapour barrier, there are a few things to remember:

- roll it out flat

- ensure that it is clean

- ensure that it is free from holes, tears and splits.

Sometimes, if a vapour barrier is to be installed over gravel or another surface with sharp edges, a layer of sand is installed between the barrier and the gravel.

The following article front HIA, provides you with the relevant information for complying with the NCC with regards to the implementation of vapour barriers.