You are required to possess knowledge of the different materials and resources suitable for the construction project. The present construction project you are undertaking possibly has similarities with completed construction projects or other relevant projects you have partaken in before.

All significant decisions and actions you will adapt in the construction project must adhere to the construction specifications, building codes and other relevant construction requirements. The construction materials that must be selected and procured must meet the construction requirements stipulated in the construction project plan and construction specifications.

Project plan

A construction project plan is a crucial part of initiating a construction project, as it outlines in detail all the essential tasks, activities, resources, scheduling, procurement steps, and the person(s) assigned to such tasks. A well-detailed project plan ensures that tasks are efficiently performed by the assigned people up to par with the work quality specified in the project plan.

A plan for a construction project details the design, physical and location characteristics of the structure or installation that is the desired outcome of the project.

As the site manager, you are the foremost responsible on laying out plans, schedules, tasks and activities for the construction project at hand.

Construction specifications

Construction specifications are the details for the work that needs to be completed in a construction. These specifications document how the construction is to be carried out by contractors and subcontractors. It specifies information on the materials, quality and scope of work, and installation process in relation to the construction project being undertaken.

Construction specifications also further detail the ration, quality and quantity of the building materials.

More particularly, construction specifications serve the following objectives:

Defining the quality and strength of constructional work

Indicating the type of building material such as brick type and timber type

Detailing the conditions of the contract

Expressing the ratio of construction materials and components to produce

Explaining the methodologies involved in getting the construction work done

Describing the machinery and tools to be utilised in the construction project

Construction specifications have three common types:

|

|

|

| Prescriptive These detail the types of installations and materials necessary in the completion of the project. These also describe the standards and requirements relevant to the construction project. |

Performance These specifications focus on the project outcome and indicate the ultimate function of the building. |

Proprietary These are the specifications that focus on only one specific product for a given installation. |

Similarly, specifications can also be classified as either open or closed.

- Open specifications - An open specification typically documents products and types of materials which the contractor can choose freely.

- Closed specifications - On the other hand, a closed specification lists construction materials, products, and systems from a defined supplier and manufacturer.

Specifications for each construction project and among construction may vary and differ in many given circumstances. However, all construction specifications are to include illustrations and further specifications of everything involved in the installation and assembly of building products, especially those that cannot be represented through illustrations and drawings.

For instance, the desired size of a door can be represented through a drawing, but not the type of door that is to be installed, nor the type of timber to produce the door. The specifications must clearly and specifically describe the quality and characteristics of the materials to be selected.

National Construction Code (NCC)

The construction project you are partaking in must be adherent with the requirements established by the National Construction Code (NCC).

The NCC is the primary code that provides technical guidelines for the design and construction of buildings and other structures in Australia. It is produced and maintained by the Australian Building Codes Board (ABCB) on behalf of the Australian Government and each State/Territory government.

The NCC is composed of three volumes: Volumes 1 and 2 constitute the Building Code of Australia (BCA) while Volume 3 is the Plumbing Code of Australia (PCA).

Compliance with the NCC

Compliance with the NCC can be achieved by meeting the following:

- General Requirements – these are the requirements provided in Volumes One, Two and Three of NCC, that outline how to use the NCC and what process should be followed.

- Performance Requirements – these are the minimum requirements for buildings, building elements and plumbing and drainage systems.

Compliance with the Performance Requirements can be shown through any of the following:

- developing a Performance Solution

- using a Deemed-to-Satisfy (DTS) solution

- using a combination of Performance Solution and DTS solution

Performance solution

This is done by directly complying with all applicable and appropriate performance requirements.

Compliance can be verified through the following assessment methods:

- Evidence of suitability

- Expert judgement

- Verification methods

- Comparison with Deemed-to-Satisfy Provisions

Deemed-to-Satisfy (DTS) Solution

This can be achieved by following all appropriate Deemed-to-Satisfy Provisions in the NCC. The Deemed-to-Satisfy Provisions are prescriptive standards commonly adapted from Australian Standards. The DTS provisions may include materials, design factors, components and construction methods that aid in meeting performance requirements.

This can be assessed by using one or a combination of the following:

- Evidence of suitability

- Expert judgement

Combination of a performance solution and DTS solution

Compliance with Performance Requirements can also be achieved by implementing a combination of a Deemed-to-Satisfy (DTS) Solution and a Performance Solution.

This can be verified by one or more of the following, as appropriate:

- Evidence of suitability

- Expert judgement

- Verification methods

- Comparison with Deemed-to-Satisfy Provisions

For instance, to comply with the NCC, a school building could utilise a combination of solutions by using Deemed-to-Satisfy Solutions for energy efficiency and sanitary facilities, and by adapting Performance Solutions for fire safety issues.

Construction requirements

Aside from the standards and requirements enforced by the NCC and BCA, your State or Territory’s building and planning legislation details specific requirements relevant to obtaining approvals for particular building work, and requirements for building work.

Below are the links to the different State and Territory’s planning and building legislations, Acts or Regulations.

|

State or Territory |

Act/Regulation |

|

Australian Capital Territory |

|

|

New South Wales |

|

|

Northern Territory |

|

|

Queensland |

|

|

South Australia |

|

|

Tasmania |

|

|

Victoria |

|

|

Western Australia |

|

Now that you have identified and read the documents relevant to the construction project, you have the necessary information to assess if the materials specified in the project plan are suitable to be used in the region.

As part of the procurement process, it is essential that the properties of the construction materials specified for the project are assessed for their suitability for the project. Some construction materials may prove to be ideal for their function in the construction in general, but not geography-wise, and vice versa.

Identifying the most suitable construction materials, products and components to utilise in the installation and assembly involved in your construction projects is a crucial part of procurement process.

The different properties that the construction materials exhibit either by themselves or when assembled together will define their suitability for the project. How the materials and products will behave when exposed to the climate and other natural phenomena in the region will determine how suitable the specified construction material is to its perceived function and utility.

This section will discuss the properties, limitations and applications of the various building materials, components and products. This section will also discuss how to assess the building materials for their suitability for the project.

Building materials

Building materials are materials used for constructing and repairing buildings and other infrastructure. Also known as construction materials, they can be naturally occurring or artificially produced. Building materials are often used to create more complex parts of a structure. For example, wood or lumber can be made into doors and fixtures of a small house. You should be able to identify and familiarise yourself with the various building materials used in your project. The following are some of the most common building materials used:

Cement

Seldom used by itself alone, cement is commonly used a binder to hold other materials together to create a new product, such as concrete and mortar. Cement has fine texture and the ability to retain its volume after it hardens. When mixed with water, cement exhibits both adhesive and cohesive properties that makes it suitable for binding durable solid construction materials. On the downside, cement has low tensile strength, low toughness and long curing time, which is why materials with cement may develop cracks.

Ceramics

Ceramics are glassy materials that are produced from a mixture of minerals and water. Ceramics have great density, hardness, are chemical-resistant, and frost-resistant. They are also environmentally stable and thus economical in terms of maintenance costs. However, when combined with other materials with higher stress, and when subjected to corrosion, problems are likely to happen. Ceramics do not have great ductility and are immensely brittle.

Most common application of ceramics is being an ingredient to make tiles and glass. Aside from that, ceramics can also be being used as cutting tools, electric insulator and thermal insulator.

Concrete

Concrete is a widely used construction material for structures like buildings, dams, bridges and roads. It is formed from a mixture of crushed gravel, sand and other aggregates, combined with a binder such as cement.

By itself, concrete has low tensile strength; thus, it needs reinforcement by steel rods and bars. It is also prone to cracking and has low ductility. However, concrete is considered to be one of the cheapest to purchase and maintain due to its high durability and compressive strength with very minimal maintenance requirements, as concrete materials do not decay, rust or burn up.

Glass

Glass is generally made from mixtures of sand and silicates. Although it is very brittle, certain technologies have made measures to increase glass’s ability to resist deformation brought about by its load.

Glass is an excellent building material for its transparency, being dustproof, waterproof, and rust resistant. When used in structures, glass tends to make the interior look big and it helps in reducing the building’s dead load. However, being brittle, glass must be handled with utmost care, especially because it cannot be acquired at a cheap price.

In construction, the function of glass varies from being used for windows, to doors and skylights. More modern designs in the industry now use glass for flooring and wall structures.

Plaster

Plaster is an artificially created building material mainly from clay, limestone or cement. Initially, it comes as a form of a powder and is mixed in water when to be used. It becomes a slimy paste that is applied quickly (since hardens quickly as well) as a protective or decorative layer for walls and ceilings.

Plaster is used for walls and ceilings since it has weather resistant properties (water, dust resistant) and it is highly adhesive. Plaster walls and ceilings do come at a steep price, and installation and maintenance are usually challenging.

There are various kinds of plaster, based on the binder utilised:

- Gypsum plaster – The most common type of plaster, gypsum plaster is produced by heating gypsum to around 150°C. This kind of plaster has the quality of being fire-resistant.

- Cement plaster – Normally applied to masonry exteriors and interiors, a cement plaster typically consists of cement, sand and water. It helps in achieving smooth surface in interiors, but it oftentimes still requires a finishing layer of gypsum plaster. Cement plaster is better than gypsum plaster in terms of moisture resistance.

- Lime plaster – Lime plaster is comprised of lime and sand, with inclusion of other fillers. It is more flexible than gypsum plaster and is most common among structures that have already endured time.

- Clay plaster – Among the four, clay plaster is the most sustainable alternative to modern plasters. It comes in various natural colours and is available with fibre additives that reinforce its strength.

Mortar

Mortar is a paste mixture of sand, a binder (e.g. cement) and water that when applied and hardens serve various purposes, namely:

- Binding bricks, stones, and other building blocks

- Filling and sealing the gaps between bricks, stones, and other concrete masonry units

- Spreading evenly the load and weight of the aforementioned building blocks

- Adding decoration

There are two common kinds of mortar:

- Portland cement mortar – It is a highly durable, quick drying type of mortar that is used in brick, block and stone masonry construction. It is limited to be mixed with sand and water only.

- Lime mortar – Lime mortar is used as an alternative to Portland cement mortar, as it has the ability to withstand normal movement without excessive cracking or debonding and has enhanced durability. In contrast, lime mortar hardens slowly and is less adhesive than Portland cement mortar.

Paint

Paint is an all-around building material primarily used as coating for walls, flooring and other surfaces. These surfaces are painted to make them weather resistant (water, heat and corrosion resistant). Paint is also used for aesthetic purposes.

For the most part, paint is easy to apply to walls and is also quick drying. On the other hand, it is also prone to dirt, dust and regular wear and tear. Therefore, surfaces are usually repainted to maintain the paint’s protective and decorative properties.

Epoxy

Epoxy resin is a material used as an adhesive ingredient, as well as for plastics, paints, coatings, primers and sealers. Artificially made, they have excellent adhesive properties as it binds to various substrates and surfaces. It can be used as an electrical insulator or a structural sealant, and it is usually corrosion resistant (resistant to chemicals and other solvents).

The downside is that it emits toxic fumes, creating a health hazard to workers. It also not quick drying, meaning it takes a long time for epoxy to completely harden.

Metals

These are materials formed by metallic bonds. They are widely utilised in construction for their durability and strength when assembled in different structural components, other building components, and pipework. One of the most common construction materials, structural steel, is considered a metal.

The presence of iron in metals creates the distinction between ferrous and non-ferrous metals.

Ferrous metals

Ferrous materials are those that are magnetic and contain iron. These metals are used for high load and low speed application.

Below are some ferrous metals, their properties and uses.

|

Ferrous metal |

Properties |

Uses |

|

Carbon Steel |

Carbon steel’s hardness can be attributed to its carbon content, which can vary among its three types: low carbon steel, medium carbon steel, and high carbon steel. Carbon steel also has high resistance against mechanical material wear. Be careful though, as the carbon content increases, the carbon steel’s ductility, weldability and impact toughness weaken. |

Carbon steel is used to manufacture drills, machine tools and blades because of its ability to keep a sharp edge. |

|

Cast Iron |

Although brittle, cast iron is hard and wear resistant. It also has high compressive strength and great castability and is cheap. |

Cast iron is usually used in machine tools, automobile engines and water pipes. |

|

Wrought Iron |

Wrought iron has excellent corrosion resistance and oxidation resistance. |

It is used for railings and fencing, barbed wires and chains. |

The primary disadvantage of ferrous metals is that they are prone to corrosion. Exposure to the sun, air and water can speed up metal corrosion and rusting. There are various protection and preservation methods for ferrous metallic materials.

Here are some methods:

Protection

- Storage of iron-containing metals in protective barriers, housing or coverings, as well as air and water-tight packaging.

- Storage areas must be covered so that it will not be under direct sunlight, rain and moisture.

Preservation

- Painting – Coating a ferrous metal with suitable paint helps preserve the metal since the surface is not exposed anymore.

- Galvanising – It is through this method that the ferrous metal is cleaned thoroughly by removing the scales. The surface is treated with diluted hydrogen chloride and is then dipped in molten zinc.

- Parkerising – Preserving ferrous metals from corrosion is done with the help of a chemical solution known as Parco. The ferrous metal is immersed for an hour or so into a hot water bath of Parco. The insoluble phosphates formed on the surface of the metal will keep the moisture away and eliminate the probability of the metal forming rust and eventually corroding.

Non-ferrous Metals

Non-ferrous metals are materials that are not magnetic. They do not contain iron and thus do not rust. Non-ferrous materials are the most ideal to be used in making liquid pipes, roofing, electrical and wiring applications. Below are some non-ferrous metals, their properties and uses.

|

Non-ferrous metal |

Properties |

Uses |

|

Copper |

Copper is a very malleable and ductile metal. It has good resistance against corrosion and high electrical and thermal conductivity. It also has low environment impacts because it is recyclable and lasts a long time. |

The common applications of copper in construction are in heating and cooling systems, and piping and tubing for water distribution. |

|

Aluminium |

Aluminium is strong and durable. On the downside, aluminium is more expensive than steel and requires special welding processes. It also easily dents and scratches given that it is lightweight. |

Aluminium is commonly used in roofs and walls, in railings and staircases, and in doors and windows. |

|

Zinc |

Zinc is a long-lasting metal, so it is common in structures like churches and government buildings that are built to last. However, the production of zinc contributes to water pollution and affects the marine ecosystem therein. |

Zinc is used for roofing, drainage systems, and wall cladding. Zinc is also ideal for roof strips, in order to prevent the growth of moss and algae. |

Although non-ferrous materials do not rust, they are still susceptible to metal corrosion if not protected or preserved. Therefore, here are ways to protect and preserve non-ferrous metallic materials:

Protection

- Storage of non-ferrous metals in protective barriers, housing or coverings, ensuring that the risk of damage (e.g. scratches) can be eliminated.

- Storage areas must be covered so that it will not be under direct sunlight, rain and moisture.

Preservation

- Anti-corrosive Coating – There are coatings that help minimise the effect of corrosion to a ferrous metal with suitable paint helps preserve the metal since the surface is not exposed anymore.

Timber

Timber or wood is another commonly used building material that is naturally occurring. Timber can be used in a variety of ways, such as for flooring panels and structural support. There are two main kinds of timber:

- Softwoods – These are types of wood milled from conifer trees (tree with needles and cones), such as pine, fir and spruce wood.

- Hardwoods – These come from deciduous trees or seed-bearing trees such as oak, mahogany and maple.

Meanwhile, sawn timbers are wood or lumber that have been cut different dimensions, usually rectangular or wedged in shape.

Timber usually provides tension resistance and high elasticity, making timber able to absorb and dissipate shock loads. Timber also is an environmentally friendly material as it greatly minimises carbon footprint since timber production has low carbon dioxide emissions and low energy consumption.

Take note though that timber only has a limited load capacity, as well as low thermal conductivity and poor sound insulation. Also, wood is also prone to rotting and termite and borer attack if not maintained properly. Therefore, you need to protect and preserve timber until it is used in building and construction. Ways to protect and preserve timber include:

Protection

- Storage of timber in proactive barriers, housing or coverings.

- Pressure Treatment – putting timber in a cylinder with high pressure vacuum and chemicals that will be mixed into the wood. Once treatment is complete, the wood will be more durable and resistant to rotting, termites and moulds.

Preservation

- Proper storage environment (away from water, moisture, wind and direct sunlight.

- Use of wood preservatives, such as zinc chloride or coal tar, either through brushing, dipping (immersion) application or pressure treatment.

Building products

Compared to building materials, building products are manufactured or processed to be used for constructing building and other structures. Building products are usually produced from a combination of building materials to create an item with improved properties. The items below are some of the common building products used.

Plasterboard

Plasterboard, also called drywall, is a panel made of calcium sulphate dihydrate and is used to make interior ceilings, partitions, and walls. Plasterboards are installed in structures to meet regulations for fire protection, thermal efficiency, and acoustic purposes.

Aside from being easy to install, lightweight and 100% recyclable, plasterboards also provide a smooth finish to be decorated for aesthetic purposes of the interior of the building. They are also reasonably priced, have low environmental impact and are even fire-resistant and water-resistant.

Take note, though, that plasterboards tend be very brittle and easy to crack or break. Plasterboard is also not suitable to be used in areas that frequently get wet or moist because of its low resistance against water. Using it in bathrooms and high-moisture rooms can cause severe damage on this component. However, measures can be taken in order to not encounter issues when using plasterboard, including applying plaster over the drywall to increase its resistance against tough impact.

Structural steel

Steel is one of the most widely used building materials used together with concrete to produce long-lasting structures. Steel is flexible and can easily adapt to being assembled with other building materials. It is usually used for channels, beams, plates and angles.

With its high tensile strength, hardness and degree of toughness, structures with structural steel can withhold ecological phenomenon such as thunderstorms, earthquakes, and cyclones. However, structural steel is expensive to maintain due to its being prone to corrosion (rust). It also loses its properties when exposed to higher temperatures and experiences a high expansion rate in changing temperatures.

Engineered timber

Engineered timber or wood is a manufactured wood through binding wood particles (e.g. scrap wood, sawdust, other by-products) or several boards of solid wood together to create a more composite and durable wood. Common types of engineered timber include:

- Plywood

- Cross Laminated Timber

- Particleboard

- Veneered Wood

Because engineered woods are manufactured, they can be processed to meet particular specifications, designs and needs, making them more versatile than solid woods. As mentioned, they can be made to be more durable and to last longer through manufacturing them to become resistant to water, rotting and termites. However, they do have their limitations, as binding engineered wood requires use of toxic adhesives, creating health risks. They are also heavier and denser compared to natural wood, making them difficult to handle and install.

‘Massive’ or Cross Laminated Timber (CLT)

This subclass of timber gets special mention as it is more stable, and its mechanical properties are less variable than other engineered wood. While CLT can be costly and has poor sound insulation, its high density and good thermal properties make it suitable to be used as floor slabs, beams, columns and shear/loading bearing walls.

Building components

Building components are parts of a building manufactured and assembled separately outside the construction site (pre-fabrication) and delivered to the site once they are ready for installation. Building components can also be fabricated on site. The commonality is that components are manufactured completely before they are installed to the building. Three common parts of a building with building components are flooring, framing and roofing.

Flooring

Hardwood flooring

Hardwood flooring, which is common in meeting halls, gymnasiums, older factories and offices, is the most ideal type of flooring due to its ease of cleaning and maintenance. Not only does it serve aesthetic purposes because of its elegant finish, but it is also long-lasting, durable, and can be easily restored and repaired should it exhibit signs of damage due to wear and tear.

However, hardwood flooring is expensive and has low resistance to atmospheric changes. Exposure to moisture, e.g. water tubing directly under it, can weaken this type of flooring.

Engineered hardwood flooring

Engineered hardwood flooring is less expensive and easier to install, especially for those who are inexperienced in construction but want to install the floorings themselves. In contrast to hardwood flooring, engineered hardwood flooring has greater resistance against warping caused by moisture present under the floor. On the other hand, some engineered hardwoods may be assembled using cheap or poor quality of wood making them more prone to wear and tear, while most tend to fade when exposed to too much radiation (e.g. UV rays from the sun).

Engineered hardwood flooring is common in houses, residential units, office buildings, and internal walkways.

Framing

In construction, framing is the act of assembling materials together to give support and shape to a structure.

Steel framing

Also known as lightweight steel framing (LSF), it is common among high-rise, warehouse and industrial buildings.

Steel framing can be installed easily and can adapt easily to any kind of shape. It also has high strength and can withstand forces such as seismic activity and wind. It is often associated with speed in construction.

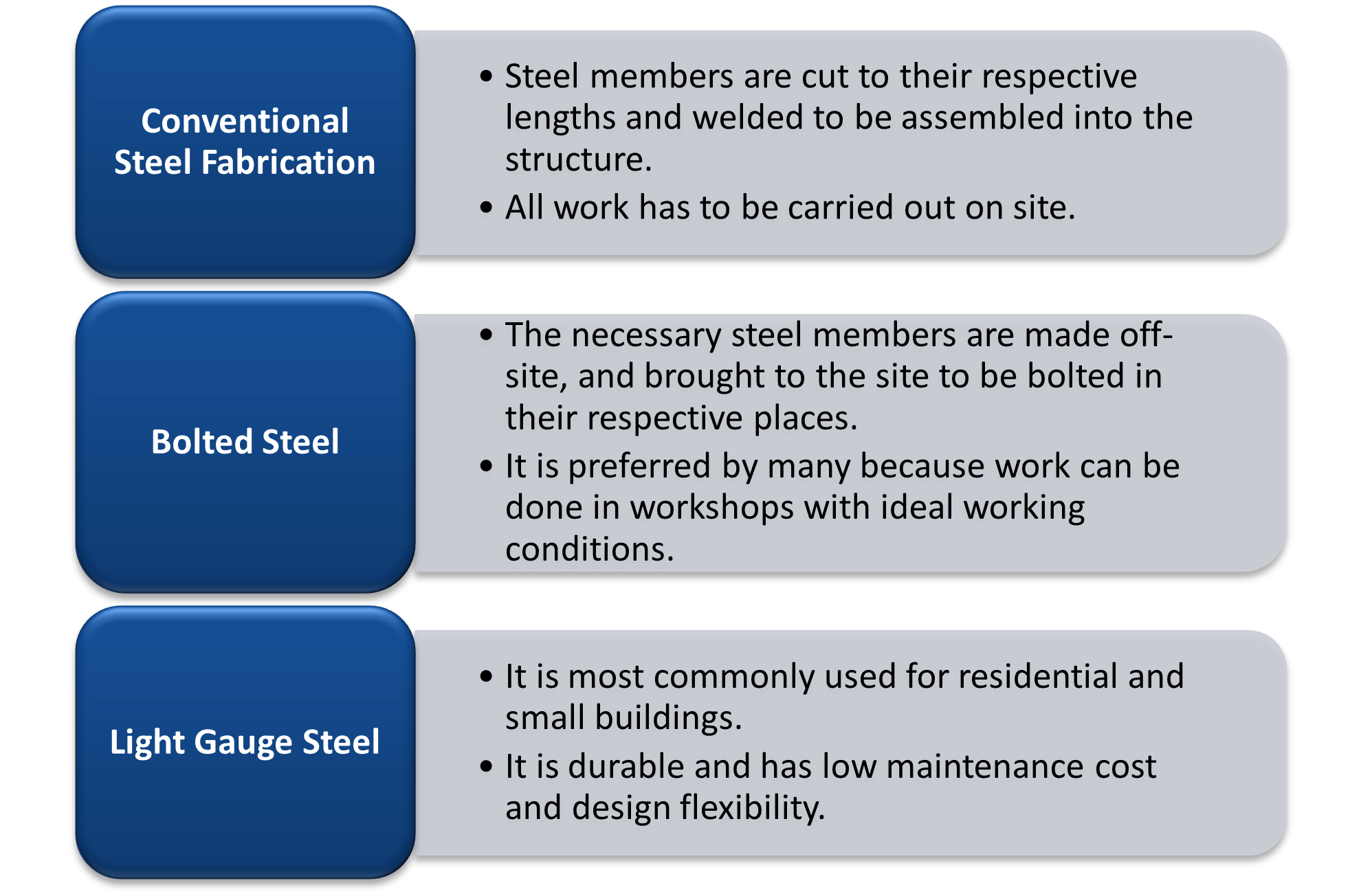

Common kinds of steel used in construction include:

Since steel is the main component of this kind of framing, it conducts heat very easily, which does not make it very ideal for structures with prolonged exposure to heat. Using steel framing will also require other components as support, such as plasterboard, insulation, etc.

Roofing

Asphalt shingles roofing

This roofing consists of asphalt, miner granules, felt and fibreglass pressed together and made into a rectangular shape with three tabs. There are various styles and colour of asphalt shingles that you can choose from.

Asphalt shingles roofing is most common among residential houses because not only is its installation easy and inexpensive, but it also has great resistance against fire. This kind of roofing also has low environmental impact because it can be recycled.

Aside from its short lifespan, another disadvantage of asphalt shingles roofing is its low resistance against damage caused by storms, winds and heat. It must be ensured that it is installed and maintained correctly in order to minimise the risks of acquiring much damage over time.

Assessing suitability of materials for the building project in the region

Once you are able to identify the various building materials, products and components, you should now move on to assessing their suitability for the project in the region. Suitability means that the materials used, considering the region they are used, are fit to the environment the materials are in. Take note that, apart from the requirements of the building project (from project plans, specifications, standards and codes), the region will play a role on the type of materials to be used in the project.

Climate

Climate is an important factor to consider when selecting the materials for the project. The weather and climate can affect the quality and durability of building materials as they will be consistently subjected to weather elements such as:

- sunlight and heat

- rain (including storms) and moisture

- snow, hail and other cold conditions

- wind

Materials to be chosen should be able to withstand these elements without much damage to them.

Geographic location

As the climate is dependent on the region you are in, you should also take into consideration the location of the project. Geographic location will most likely dictate the type of climate of a region.

For example, places near the outback have a dry and arid environment, prone to direct sunlight and risk of bushfire. Therefore, you should use materials that are not easily flammable and do not deform in high heat.

Regions in the southwestern and south-eastern part of Australia have a temperate climate, which brings flexibility on the materials to use. Be wary also of regions prone to cyclone hits and frequent raining, such as the tropical north region.

Geographic location should also consider the likelihood of an earthquake occurring. Although earthquakes occur less often in Australia compared to other parts of the world, they still do happen. You may consult relevant agencies, such as Geoscience Australia, to get necessary information on earthquake occurrence on the region of the project.

Once you have identified the materials needed and their corresponding properties, and assessed their suitability to the building project and its region, you should now focus on evaluating materials on three important points:

|

|

|

| Quality | Compatibility | Compliance |

Quality of materials

The first criterion to evaluate materials with is through the quality of materials.

Quality refers to the characteristics of a material that makes it fit for the purpose of the building or structure. This means that the material functions as it has been manufactured. For example, steel that is of good quality does its job of reinforcing concrete to be able to hold up the building structurally, without substantial damage or failure to the material.

Quality of materials can be evaluated through quality standards. These standards are created so that quality of materials remain consistent across all buildings and structures. The standards dictate certain minimum requirements that deem a material as top quality. Different materials have different standards to meet. Therefore, extensive knowledge on these standards will help you determine the quality of materials you are going to be acquiring.

Compatibility of materials

The compatibility of the materials must be highly considered in selecting and purchasing materials to ensure that when the particular material will be assembled together with other construction materials, it will not result to any damage; thus, the construction materials can serve their purpose to the fullest.

As early as the canvassing stage, it is important to note which types of products and materials are compatible and which materials, when assembled together, will cause more damage than good.

On the following pages are some examples of damage that can be caused if the compatibility of materials is not considered in a structure.

Example 1:

Asphalt roofing materials contain solvents that can damage (poly)urethane sealants. The asphaltic materials contain solvents and plasticisers that dissolve and discolour urethane. The point of contact of asphalt materials with (poly)urethane sealants will result in discolouration of the sealant, eventual delamination of the sealant, and, possibly, the softening and deterioration of one or both materials.

Example 2:

Steel is the most common reinforcement used in concrete and normally provides reinforcing steel with excellent corrosion protection. However, the deposition of de-icing salts on reinforced garage floors can result in corrosion of the steel. As the steel corrodes, it increases in volume and causes the concrete to spall.

In order to evaluate if materials are compatible with one another, you need to consider the different properties they exhibit. Often, the chemical properties of other materials will dictate their compatibility with one another. The more resistant to chemical change (e.g. rusts, stains, corrosions) a material is, the more compatible a material is with another material. This is not only to reduce the risks of damage in the structure, but also to minimise the expenditures involved in the process.

Again Standards Australia provides the needed standards on preparing and evaluating material testing in order to check compatibility. You can search for the specific material you intend to test to find relevant Australian Standards on them.

Compliance of materials

Compliance is concerned with meeting specific requirements other than the quality of materials. Usually these requirements are dictated by the industry or the government. In Australia, building and construction materials should be compliant with the requirements and other provisions found in the National Construction Code (NCC).

According to the NCC, there are two classifications of products that do not comply with standards and requirements stipulated in relevant construction documents. These two classifications are:

Non-conforming building products (NCBPs)

These are products and materials that do not actually meet the characteristics and standards for their intended use. These products may be supplied or marketed with the goal to deceive their clients. For instance, a building product that is advertised as highly corrosion-resistant but is actually easily corrosive is a non-conforming building material.

Non-compliant products (NCPs)

These are products and materials that are used in conditions and situations that do not adhere with the requirements and standards of the NCC. For example, a combustible building material that is used in a situation in which the NCC requires a non-combustible product is a non-compliant product and is not fit for purpose.

You can check compliance of materials through the following methods:

- Testing – This involves performing tests on samples of materials.

- Inspection – This means actual inspection of the design, production, installation or performance of materials in place.

- Declarations – They include formal statements provided by the suppliers on the quality or performance of products or materials based on the tests they have done to them.

- Certification – It involves an assessment body performing formal statements if compliance based on its evaluation of the product or material.

All stages and procedures involved in the construction process have an impact on the environment, whether subtle or overt. These stages and procedures include the sourcing of the material, the transportation of the material from the source to the building site, the storage process, the construction process itself, and the waste disposal process to cap off the project.

Aside from the quality, compliance and compatibility, your choice of the construction materials must also include considering the different environmental impacts the different construction materials have.

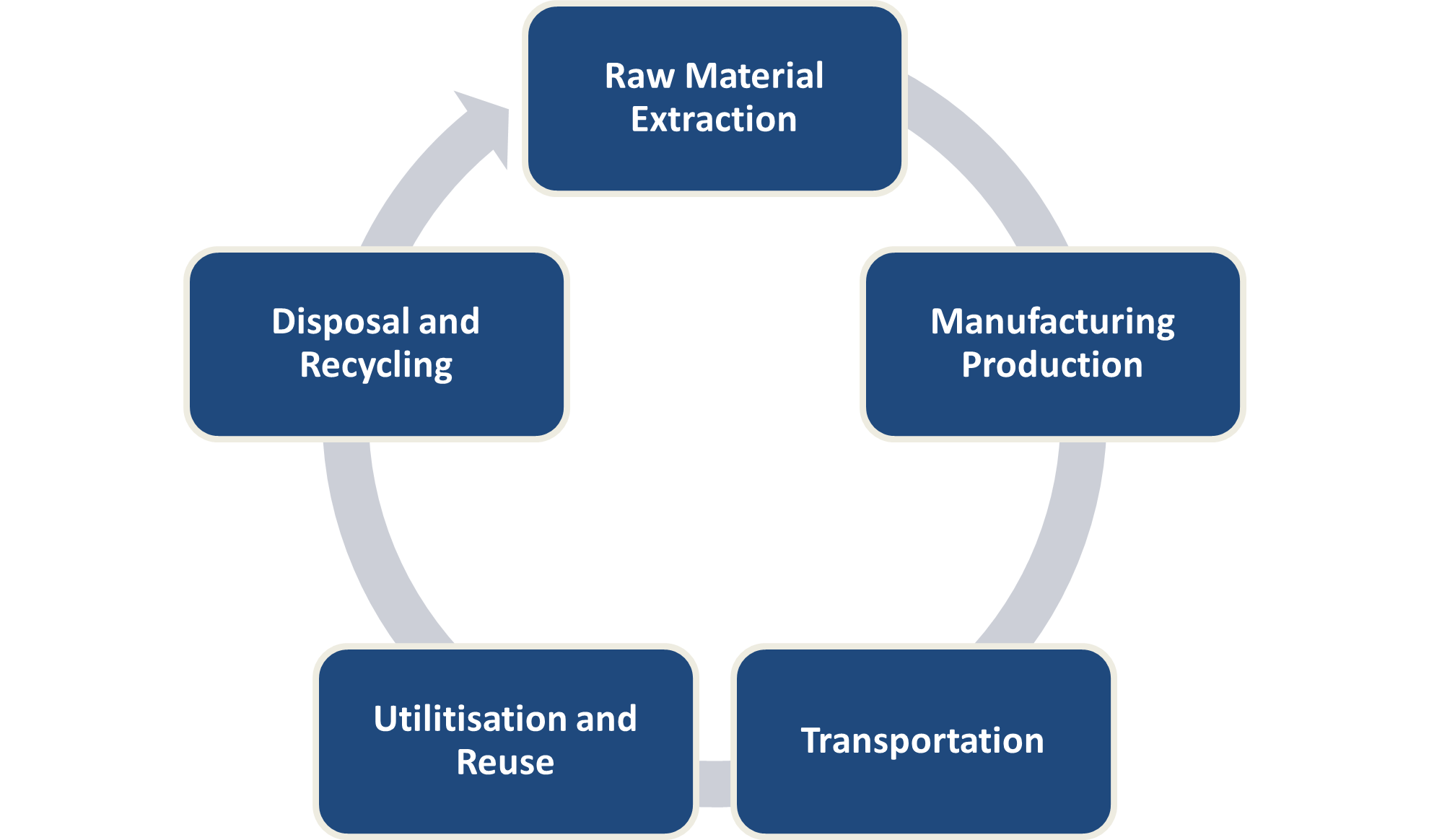

Life cycle of construction

Before identifying the different environmental impacts of construction material, it is important to understand first the life cycle of construction materials, as illustrated below.

The life cycle of construction materials starts with the extraction of raw materials. These raw materials are then brought to the suppliers’ and manufacturers’ factories and plants where they will be turned into the construction materials that will be selected for procurement. Once a purchase order has been given for these construction materials, they are then transported to the site of construction, where they are then utilised for their intended purpose.

The table below details the key environmental impacts each stage in the construction materials life cycle causes.

|

Stage in Construction Materials Life Cycle |

Environmental Impacts |

|

Extraction |

|

|

Manufacturing |

|

|

Transportation |

|

|

Utilisation |

|

|

Disposal/Recycling |

|

Knowing how the life cycle of construction material contributes to adverse environmental harms should influence your choice of building materials. As much as possible, in defining and deciding on the building materials you identify as the major components and materials to be used in your construction, you should also try to consider the following:

- the implications of mineral extraction to acquire the specific building material

- the implications of the production process

- the toxic elements the production process contributes

- disposal and waste issues at every stage in the process

- issues that arise in transportation or distribution

- lifecycle and reusing options at the end of the material’s expected life

Embodied energy

The energy consumed in all of the processes involved in construction is known as embodied energy. Embodied energy quantifies the total sum of energy required to acquire, produce, or manufacture the construction materials. Each building material contributes to the embodied energy of a building; thus, your choice of materials, preferably those with lower embodied energy, can significantly change the embodied energy of a full structure or building.

Since assessing the embodied energy of construction material is often difficult to assess, complex and varies across several circumstances, Process Energy Requirement (PER) is used to make embodied energy easier to be quantified. PER is a measure of the energy generated during the production stage which includes the transport of the raw materials to the manufacturer.

Below is a table that shows embodied energy, expressed in PER, of some construction materials.

|

Construction Materials |

PER embodied energy (MJ/kg) |

|

Hardboard |

24.2 |

|

Particleboard |

8.0 |

|

Plywood |

10.4 |

|

Glue-laminated timber |

11.0 |

|

Laminated veneer lumber |

11.0 |

|

Plastics - general |

90.0 |

|

PVC (polyvinyl chloride) |

80.0 |

|

Synthetic rubber |

110.0 |

|

Acrylic paint |

61.5 |

|

Stabilised earth |

0.7 |

|

Gypsum plaster |

2.9 |

|

Plasterboard |

4.4 |

|

Fibre cement |

4.8 |

|

Cement |

5.6 |

|

Clay bricks |

2.5 |

|

Construction Materials |

PER embodied energy (MJ/kg) |

|

Concrete blocks |

1.5 |

|

Glass |

12.7 |

|

Aluminium |

170.0 |

|

Copper |

100.0 |

|

Galvanised steel |

38.0 |

Certainly, the production of construction materials that involve various mechanical and chemical processes results to more embodied energy than the building products and materials that can be sourced from nature and which are sustainable.

Life cycle assessment

Life Cycle Assessment (LCA) is a process that examines the total environmental impact of a building product or material all through every stage and process it has to undergo in its usual life cycle. In LCA, you go into a substantial enquiry of what transpired in the life cycle of the construction materials. Specifically, you may consider some of these questions:

- How much water and energy were used during each stage of the life cycle?

- Were there emissions from transportation (land, rail, air or freight)? of the product from extraction to installation?

- If yes, how can these be reduced?

After identifying the different effects of each stage in a construction material’s life cycle to the environment, a figure, or several, that represents the general environmental impact of the product is produced. This is to quantify the consequences of the product or activity to the environment.

The tools used in Life Cycle Assessment can be classified into three levels, namely:

Product comparison tools

Approaches in this level focus on the individual materials and components. The energy yielded by each construction material is summed together to indicate the life cycle assessment for the entire building.

Tools such as Gabi and Umberto which are utilised in Germany and SimaPro in Netherlands are tools classified in this level.

Whole-building design / decision support tools

Tools in this level, like the internationally recognised One Click LCA and Athena for Canada, are those that consider the entire building as its starting point. In this level, for instance, you may start with the shape of the building and then work your way down to the choice of building materials in the different components.

Whole-building assessment frameworks or systems

In this particular level, approaches are those that have comparative scoring systems which can be utilised in all circumstances where it applies across the building industry. Approaches in this level are considered a method of benchmarking different buildings based on their environmental performance.

The whole life cycle of the product is being assessed, while at the same time considering the sustainability and health aspects of the building in question.

Ultimately, the Life Cycle Assessment in construction is a way to holistically grasp the effects of the whole life cycle of building materials on the environment. Any organisation or group that utilises LCA to evaluate their environmental performance is not only able to gain valuable information on how they contribute to global warming, ozone depletion, and other environmental issues, but is also able to realise significant steps they can take to reduce the environmental harms they cause, although indirectly.

Naturally occurring materials

Aside from materials manufactured exclusively for construction purposes (e.g. steel, brick, glass, metal, concrete), naturally occurring substances such as straw bale, cob, bamboo, earth bags, and rammed earth are also used in construction.

As discussed in the previous chapter, the mere manufacturing of construction materials bears great consequences on the environment; thus, choosing to use materials that are natural and can easily be accessed from your surroundings helps in reducing the impacts of the construction life cycle to the environment.

Using naturally occurring materials entails a decrease in carbon emissions, human toxicity, depletion of fossil fuels, and other environmental harms that the mechanical manufacturing of the usual construction materials cause.

The following are some naturally occurring materials that can be converted into materials and products used in construction:

- Cob

- Bamboo

- Natural fibres

- Rammed Earth

Cob

Cob is a construction material that has been used since prehistoric times. It is an all-natural material made from subsoil and other fibrous organic materials such as straw, which add to its strength. Aside from being sustainable, or requiring very little energy to produce and acquire, cob also has the ability to resist fires and seismic activity.

Bamboo

With a strength similar to timber, bamboo is mainly used for bridges, scaffolding, and houses especially in places where it is in abundance. Aside from being renewable and sustainable, bamboo can withstand a maximum temperature of 4000 C and has higher tensile strength in comparison to steel. Bamboo is also easy to install, transport and assemble due to its weight. Using bamboo in structures poses no risk to the health of anyone concerned and adds a higher sense of security for areas prone to earthquake, like certain regions in Asia.

Natural fibres

Natural fibres such as thatch, grass and reeds have been used since ancient times particularly for natural dwellings. They can either be used by themselves or used together with other building materials.

These natural fibres are durable and can be sourced locally. Thatch roofing can be waterproof if installed properly. It also has good acoustic and thermal properties. Reed constructions also have good resistance to seismic activity, good strength-weight ratio and high tensile strength.

Rammed earth

A mixture of aggregates like sand, gravel, clay and silt placed between flat panels make up rammed earth. Having great strength, rammed earth can be used for loadbearing structures in multi-storey construction. It also has good resistance against vermin infestation and fire. Although highly durable, rammed earth can be subject to degradation if exposed to too much moisture.

Impact of construction tolerances

When naturally occurring materials are converted or repurposed into the building materials, you not only replace unavailable or unsuitable building materials; you also move towards a more sustainable method of construction. However, conversion of natural materials into useful building materials can be influenced by factors (e.g. weather and transport) that can eventually alter their quality. Some unforeseen circumstances may lead to a change in the material’s intended and desired quality, leading to imperfections in the materials. It is for this reason that acceptable tolerances are established and are to be reviewed in converting organic materials into construction materials.

Construction tolerances are acceptable variations or deviation to quality of a material from the standard or specification. This means construction materials can be deemed compliant to the standard or specification if it falls under the tolerance of a material. This is important because, as discussed, materials most likely will not meet the required specification 100% of the time. By implementing tolerances, you can easily procure natural materials without worry of being not compliant as long as it is still within the materials’ tolerance; materials outside the tolerance can be confidently considered defective and inappropriate for building use.

In Australia, States and Territories have their own guide on the Standards and Tolerances. The tolerances found in the guide are mainly based on the National Construction Code Volumes One and Two (i.e. the Building Code of Australia). Tolerances are also based on the industry standards from Australian Standards (either through the BCA or directly through the guide). Although the guide itself is only an advisory document, compliance is still mandatory in a way that consistently references the NCC, which is adopted into law by regulation.

The table below lists the Standards and Tolerance guide of each State and Territory with links to their respective websites.

|

Construction Materials |

Guide to Standards and Tolerance |

|

Australian Capital Territory |

|

|

New South Wales |

|

|

Northern Territory |

|

|

Queensland |

|

|

South Australia |

|

|

Tasmania |

|

|

Victoria |

|

|

Western Australia |

As you have learned from the discussion of the life cycle of construction material in the previous section, there are certain processes involved in each stage that do not only affect the environment but are also susceptible to influences from external factors.

Material assembly and installation

Material assembly in construction is the combination of construction materials for a specific function. For instance, the mixture of cement, water and aggregates make up concrete, which is then reinforced by rods and steels for added strength and durability.

Installation, on the other hand, is the act of erecting or putting up a structure, or a particular component of the construction.

In both assembling the building materials with other construction materials and installing structures, it is all but natural that the building products and materials may have a slight variation than what was specified in the relevant documents or was originally expected. The materials assembled or installed may not be able to completely meet the prescribed standards while at the same time not entirely qualifying as a defective or damaged installation or assembly.

Material assembly and installation tolerances

Just like tolerance in materials (discussed in Section 1.5.2), there is an allowable tolerance when it comes to the assembly and installation of the materials. Also, as discussed in the said section, tolerances are regulated by the local States and Territories of Australia. The appropriate guides to Standards and Tolerances (also linked in the previous section) also set out provisions to meet specific Standards, including those mentioned in the National Construction Code and Building Code of Australia.

As a reference and an example, listed below in the table are various Australian Standards used as benchmarks for different areas of construction.

|

Standard |

Description |

|

AS 1684 |

Residential timber-framed construction |

|

AS 1860.2 |

Particleboard flooring - Installation |

|

AS 2047 |

Windows in buildings - Selection and installation |

|

AS 2783 |

Use of reinforced concrete for small swimming pools |

|

AS 2796.1 |

Timber – Hardwood – Sawn and milled products |

|

AS 2870 |

Residential slabs and footings |

|

AS 3958.1 |

Ceramic tiles – Part 1: Guide to the installation of ceramic tiles |

|

AS 3958.2 |

Ceramic tiles – Part 2: Guide to the selection of a ceramic tiling system |

|

AS 3700 |

Masonry structures |

|

AS 4440 |

Installation of Nail-plated Timber Roof Trusses |

|

AS 4773.2 |

Masonry in small buildings – Construction |

|

AS/NZS 1839 |

Swimming pools – Premoulded fibre-reinforced plastics – Installation |

|

AS/NZS 3500.3 |

Plumbing and drainage – Part 3: Stormwater drainage |

|

AS/NZS 4386.1 |

Domestic kitchen assemblies – Kitchen units |

It is very important to review the guide to Standards and Tolerances to familiarise yourself with the acceptable tolerances dictated by the Australian Standards mentioned. Take note that this will differ slightly depending on the location of your project since States and Territories might have different applications for the Standards.