Welcome to Industry 4.0

This unit aims to introduce Industry 4.0 terminology, concepts and technologies and their application across various industries, as well as the characteristics and advantages Industry 4.0 technology solutions can provide when applied in advanced manufacturing systems.

Learning Outcomes

This unit has been designed to provide you with an introduction to Industry 4.0 and its application in advanced manufacturing processes. This course should provide:

- awareness of Industry 4.0 principles and terminology and the emergence of Industry 5.0;

- insight into developing technological advances and their applications within Industry 4.0 environment to understand and drive innovation

- the ability to identify examples of the enabling technologies of Industry 4.0 applications; and

- an understanding of the benefits of Industry 4.0 for industrial processes.

Course Content

Topics covered include Industry 4.0 terminology, concepts and technologies and the Internet of Things (IoT), as well as introductions to 3D printing, industrial robotics systems, Cyber-physical systems and Advanced Manufacturing applications. A list of additional resources and suggestions for further study are also included. This course is intended to be delivered by online learning.

The course will take approximately 2 to 3 hours to complete, although there is the flexibility to complete the six topics in 20 to 30-minute sessions. At the end of the course, you will be asked a number of questions to confirm your understanding of the content covered.

Industry 4.0, or the Fourth Industrial Revolution, refers to the automation of traditional manufacturing and industrial processes, using modern smart technologies combined with digitised information and cloud technology storage capabilities.

Industry 1.0 to Industry 4.0

Industry practices have evolved through developments in technology from 1.0 to 4.0.

1760 to 1830

Industry 1.0

The First Industrial Revolution is also called the Industrial Revolution. It occurred in the period 1760 to 1830, with technological and architectural innovations, high rates of growth in steam power due to using coal as a more energy-dense source than burning wood, and iron production occurring after 1800. Mechanised textile production increased the quality and rates of production in factories and radically changed the nature of work. The term Industrial Revolution appears to have been first used in 1799 and referred to the transition from hand production methods in agriculture and handicrafts to mechanised manufacturing and the factory system.

1800’s to early 1900’s

Industry 2.0

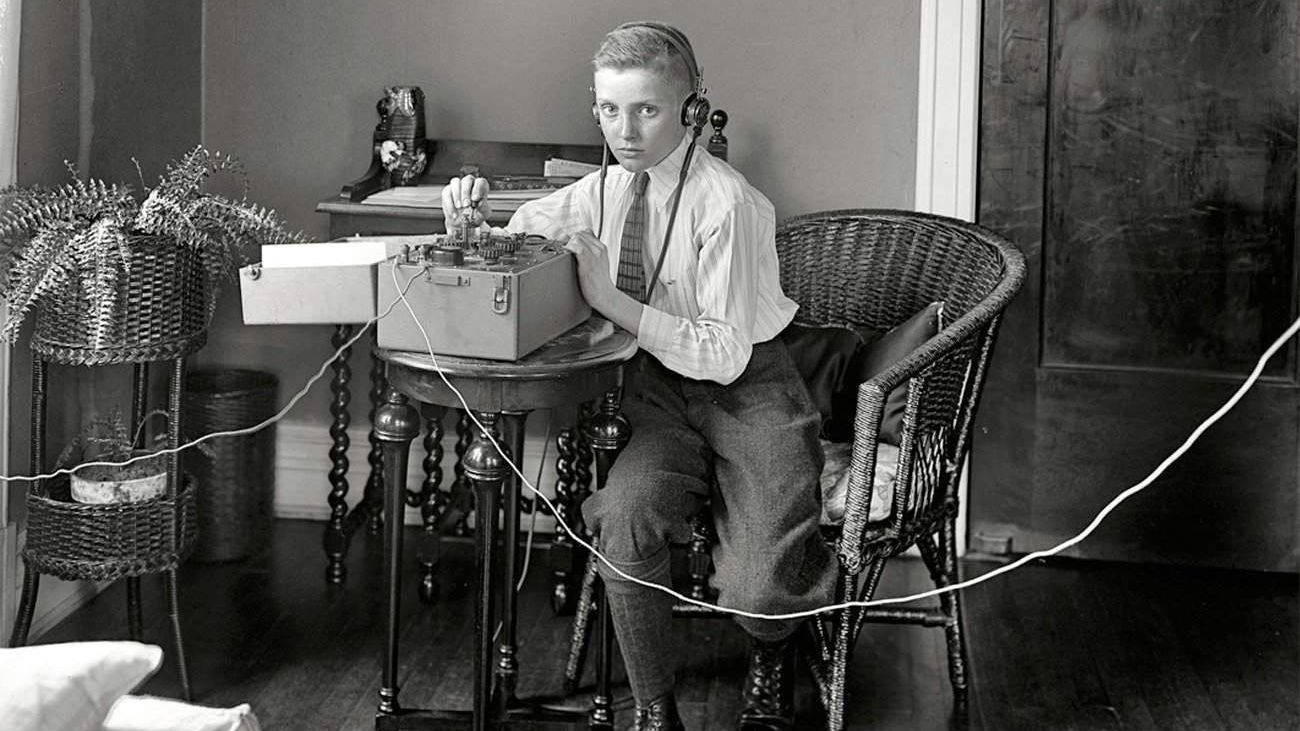

The Second Industrial Revolution, also called the Technological Revolution, involved a phase of rapid scientific discovery, standardisation, mass production and industrialisation from the late 1800s into the early 1900s. Burning oil instead of coal was found to be more energy-dense. It was a period of growth for pre-existing industries and the expansion of new industries, including steel, oil and electricity. Manufacturing and production methods were improved. For example, steel replaced iron in the building industry. Being strong and cheap to produce, it allowed railway lines to be constructed at lower costs and helped the spread of transportation. Steel also made it possible to build larger ships, skyscrapers and more ambitious bridge designs. Electrification of cities was made possible with improved communication systems from new inventions, such as the telegraph, and then the telephone from developments in physics. The internal combustion engine was another invention during this period. It fundamentally changed transportation systems and the distribution of goods.

Mid-1990s

Industry 3.0

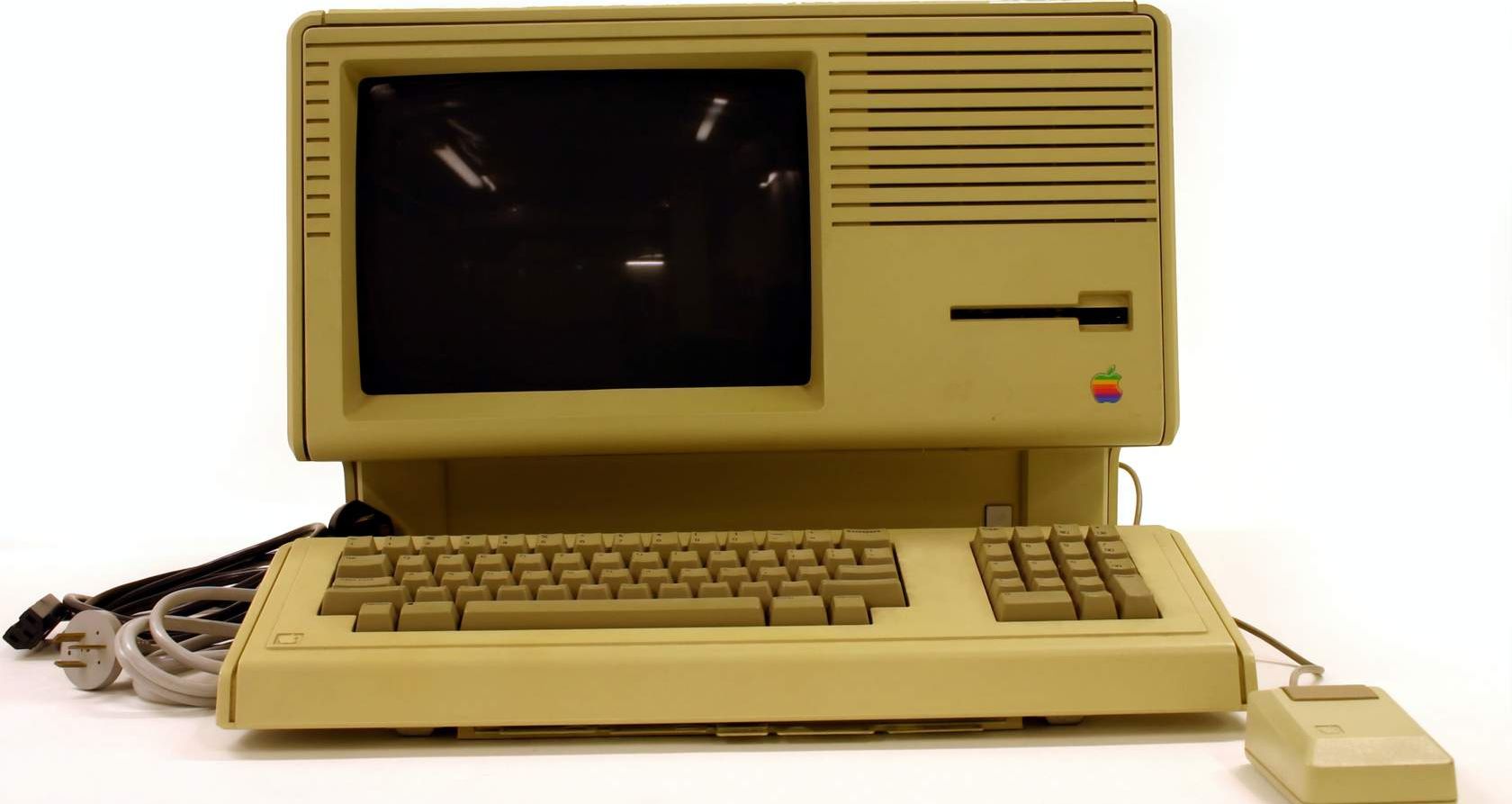

The Third Industrial Revolution, also called the Digital Revolution, involved the move from mechanical and analogue electronic technology to digital electronics from the mid-1990s, when desktop computers could be linked for the first time by Tim Berners-Lee’s World Wide Web and Marc Andreesen’s Mosaic/Netscape system. The use of digital computers for work and leisure is now common, and the Internet has made it possible for people to be connected across the world through email and social media sites. Industry 3.0 is characterised by more efficient use of the Internet, emerging sources of energy and electronic peer-to-peer financial systems. Solar power has become an important new energy source, as well as other alternatives to coal-generated electricity, such as wind and wave power. Further developments should improve the energy production efficiency of these technologies in coming decades.

Early 2000s

Industry 4.0

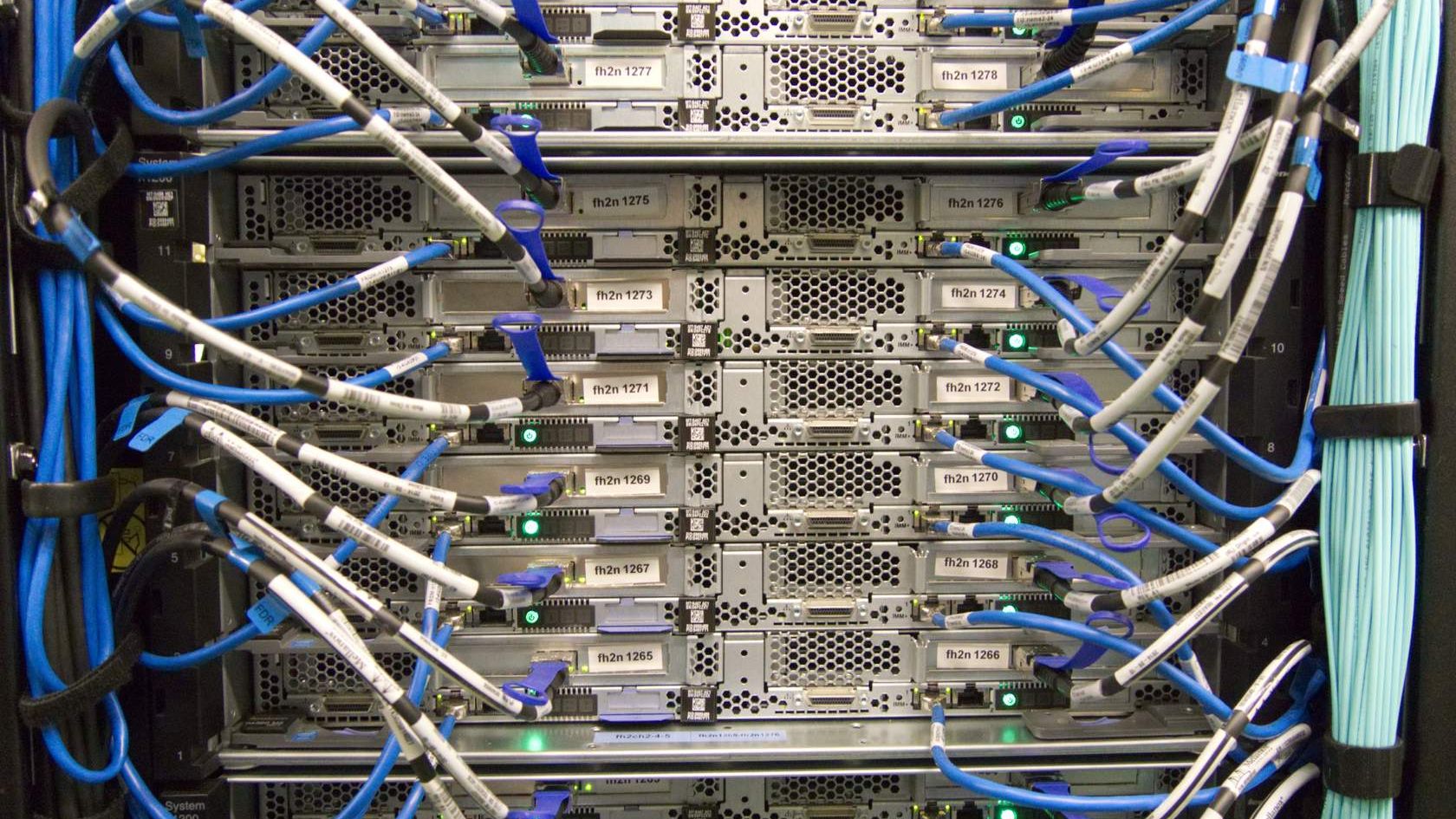

The Fourth Industrial Revolution is characterised by a global push for greater use of “green” energy sources and emerging technologies that will increasingly allow for greater automation and control through clever interconnection of digital devices. Widespread adoption of processes making use of the ‘Internet-of-Things’ is still a few years away but could lead to advancements in areas such as healthcare through developments in biotechnology. However, processes will need to be supported by far more stable internet, better cybersecurity, and lower component and set up costs before they are taken up on a wider scale. The increasing use of machine learning and Artificial Intelligence or AI is expected to have a significant impact on humanity in terms of work, leisure and everyday living within the next 10 years or so. New approaches to finance have emerged from advances in technology and connectivity, as well as improved electronic data storage systems from cloud technologies. This will also have a marked impact on current financial systems. There is a general hope that new innovations could provide positive changes in the standards of living all over the world, from lower-cost and more-efficient solutions to human needs.

Fourth Industrial Revolution Technologies

Industry practices have evolved through developments in technology from 1.0 to 4.0. Just some examples of Fourth Industrial Revolution technologies include:

Everyday Living

The fourth industrial revolution has many applications in our everyday living.

Some examples of everyday applications of Industry 4.0:

![[ADD IMAGE'S ALT TEXT]](/sites/default/files/Applications%201.jpg)

![[ADD IMAGE'S ALT TEXT]](/sites/default/files/Applications%202.jpg)

![[ADD IMAGE'S ALT TEXT]](/sites/default/files/Applications%203.jpg)

![[ADD IMAGE'S ALT TEXT]](/sites/default/files/Applications%204.jpg)

![[ADD IMAGE'S ALT TEXT]](/sites/default/files/Applications%205.jpg)

The benefits of Industry 4.0:

Optimises People, Processes and Equipment

- Provides opportunity for employees to develop new skills.

- Competitive advantages through smart production processes, services and solutions.

- Improved operational efficiencies, with more efficient equipment controls leading to greater profitability.

Boots Productivity

- Potential for market growth, with shorter new product development time and the ability to repidly adjust manufacturing settings for new product production.

Improves Operational Reliability and Customer Satisdaction

- Increased customer satisfaction with reliably consistent production methods, better product quality, reduced production time and timely distribution.

Advanced Manufacturing

It involves the use of innovative technologies to automate and improve the performance of manufacturing processes and enhance production efficiency.

Advanced manufacturing includes the use of digital technologies and processes, such as:

- advanced robotics;

- Computer Aided Design (CAD);

- Computer Aided Manufacturing (CAM);

- Computer Aided Engineering (CAE);

- High Performance Computing (HPC) for modelling, simulation and analysis;

- rapid prototyping or additive manufacturing;

- automation processes for rapid manufacturing;

- Digital Control systems to monitor processes;

- sustainable and green systems and processes;

- Custom Manufacturing processes; and

- scalable volume manufacturing.

Watch the video below to learn about the CSIRO Advanced Manufacturing Roadmap for Australia:

You can download the CSIRO Advanced Manufacturing Roadmap document here:

https://www.csiro.au/en/work-with-us/industries/manufacturing/advanced-manufacturing-roadmap

Smart Factories

A Smart Factory is a fully digitalised factory model that utilises an interconnected network of machines, communication mechanisms and computing power through sensors that continuously monitor the system. The Smart Factory can be considered as a cyber-physical system that uses advanced technologies, such as machine learning and artificial intelligence (AI), to constantly collect and analyse data, drive automated processes and learn as it goes. This allows the system to report and respond appropriately when changes need to be made, often without human intervention.

Watch the video below to learn about Swinburne's own Smart Factory for students:

Find out more about the Swinburne–Siemens Mindsphere Application and Demonstration Centre here. https://www.swinburne.edu.au/research/platforms-initiatives/factory-of-the-future/our-partners/

Smart Farming

Smart Farming involves the integration of modern Information and Communication Technologies (ICT) with agricultural practices to monitor and control agricultural processes.

Select each tab to learn about the three interconnected technologies commonly used.

Management Information Systems (MIS)

Digital systems used for monitoring, collecting, processing, storing and disseminating data in a form that allows the farmer to carry out their farm’s operations and functions efficiently.

Precision Agriculture

The management of data related to changes in spatial and temporal conditions used to improve economic returns from the analysis of inputs and help to reduce potential environmental impacts. Decision Support Systems (DSS) are used for whole farm management using GPS, GNSS, aerial images by drones and hyperspectral images from satellites to create maps showing changes in crop yield, terrain features/topography, organic matter content, moisture levels and nitrogen levels.

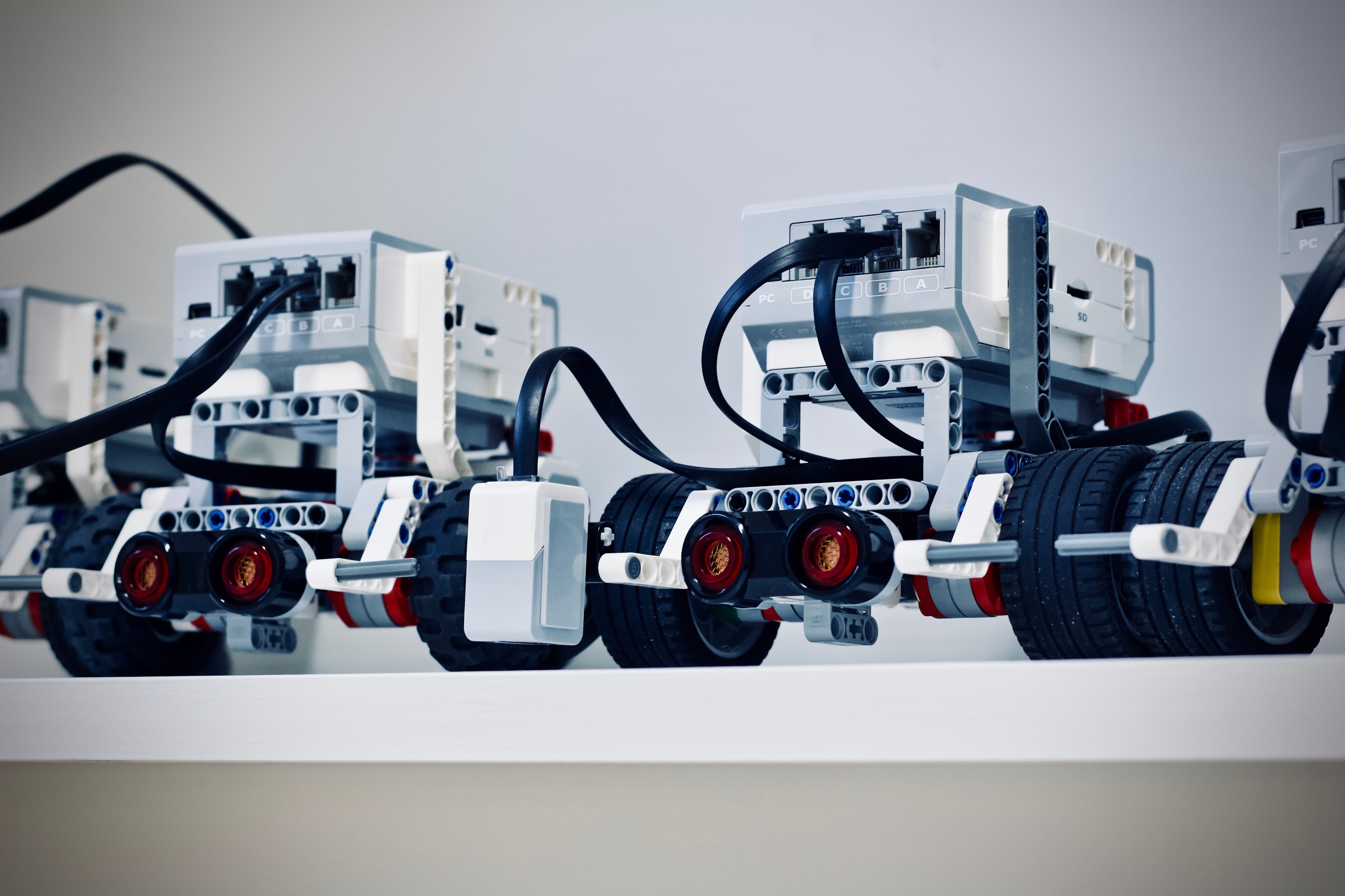

Agricultural Automation and Robotics

The use of robotics, automatic control and artificial intelligence techniques to manage agricultural production, including the use of farm bots and farm drones that have the capability to collect data on changes in growing conditions for monitoring purposes.

Watch the video below to learn about Smart Farming in Australia:

We stand on the brink of a technological revolution that will fundamentally alter the way we live, work, and relate to one another. In its scale, scope, and complexity, the transformation will be unlike anything humankind has experienced before. We do not yet know just how it will unfold, but one thing is clear: the response to it must be integrated and comprehensive, involving all stakeholders of the global polity, from the public and private sectors to academia and civil society.World Economic Forum, Global Agenda, Fourth Industrial Revolution, Klaus Schwab, Founder and Executive Chairman, World Economic Forum, 14 Jan 2016. The Fourth Industrial Revolution: what it means and how to respond | World Economic Forum (weforum.org)

Time has now moved on, and already the emergence of Industry 5.0 has been slated, with more advanced technologies being developed that appear to herald the next stage of manufacturing and other digitally controlled processes. The future could involve utilising AI to have people working alongside robots and smart machines. Robots helping people to work faster and more efficiently using advanced technologies such as the Internet of Things (IoT) and Big Data. AI is expected to extend the benefits of Industry 4.0 fundamentals such as automation and digitised efficiency.

In this module, you were introduced to each industrial revolution from Industry 1.0 to Industry 4.0. Future technological advancements moving us towards Industry 5.0 were also considered, as technology continues to evolve at an ever-increasing rate.

This module aimed at developing your understanding of the key advancements in technology that each stage of the industrial revolution has historically been built on, as well as the technological developments that have led to each successive stage of industrial revolution. Take the knowledge check below to test your understanding for this module.

Knowledge Check

Below is a collection of items that align to the four different stages of industrial revolution, Industry 1.0 to Industry 4.0.

Insert activity here.

Swinburne's Advanced Manufacturing and Design Centre

Swinburne University of Technology has officially launched its $100 million Advanced Manufacturing and Design Centre (AMDC), which will help to enhance Australia's manufacturing sector.

Links:

- Swinburne Factory-of-the-future:

https://www.swinburne.edu.au/research/platforms-initiatives/factory-of-the-future - Testlab, a CSIRO and Swinburne collaboration:

https://www.csiro.au/en/work-with-us/services/research-and-development/Prototyping/Testlab https://www.swinburne.edu.au/about/strategy-initiatives/industry-4-0/ - Australian advanced manufacturing:

https://www.globalaustralia.gov.au/industries/advanced-manufacturing