Industrial Robotics Systems are used widely in manufacturing to automate production processes and increase productivity. Industrial robots are automated, programmable and capable of movement in three or more axes.

Common automation applications for industrial robotic systems are diverse and customisable, making them useful to many industrial applications. Materials handling, assembly or disassembly of components, painting, welding, dispensing, cutting and heavy lifting are some examples. Other applications make use of an industrial robot’s ability to deftly ‘pick and place’. For instance, the electronics industry uses it to make printed circuit boards. The ‘pick and place’ technique can also be used for packaging and labelling on an assembly line.

Industrial robots can be equipped and programmed to perform many different types of automation.

Watch this video to learn about Automation and Robotics by Swinburne Innovation Malaysia & the Centre for Digital Futures:

Industrial robots can complete certain tasks much faster, to a higher degree of accuracy and more efficiently than humans, as they are designed and built to perform particular tasks with higher accuracy.

Using industrial robots can improve working conditions and safety for human workers in factories or production plants. Robots don’t fatigue like human workers and, if optimised and maintained regularly, robots don’t tend to make dangerous mistakes. Repetitive strain injuries are not an issue for robots, and they have the capacity to work 24/7.

Despite a high initial capital cost, installing industrial robotics systems can lead to increased profitability. Some robotic systems have the capacity to be reprogrammed to allow for product customisation or redeployment to other tasks.

Learn about the advantages and disadvantages of installing industrial robotics systems:

Advantages:

Disadvantages

In 2020 it was estimated that there were over 1.6 million industrial robots or robotic systems in use worldwide across the areas of agriculture, technology, medicine, transport and particularly in the manufacturing industry.

Learn about the six main types of industrial robots:

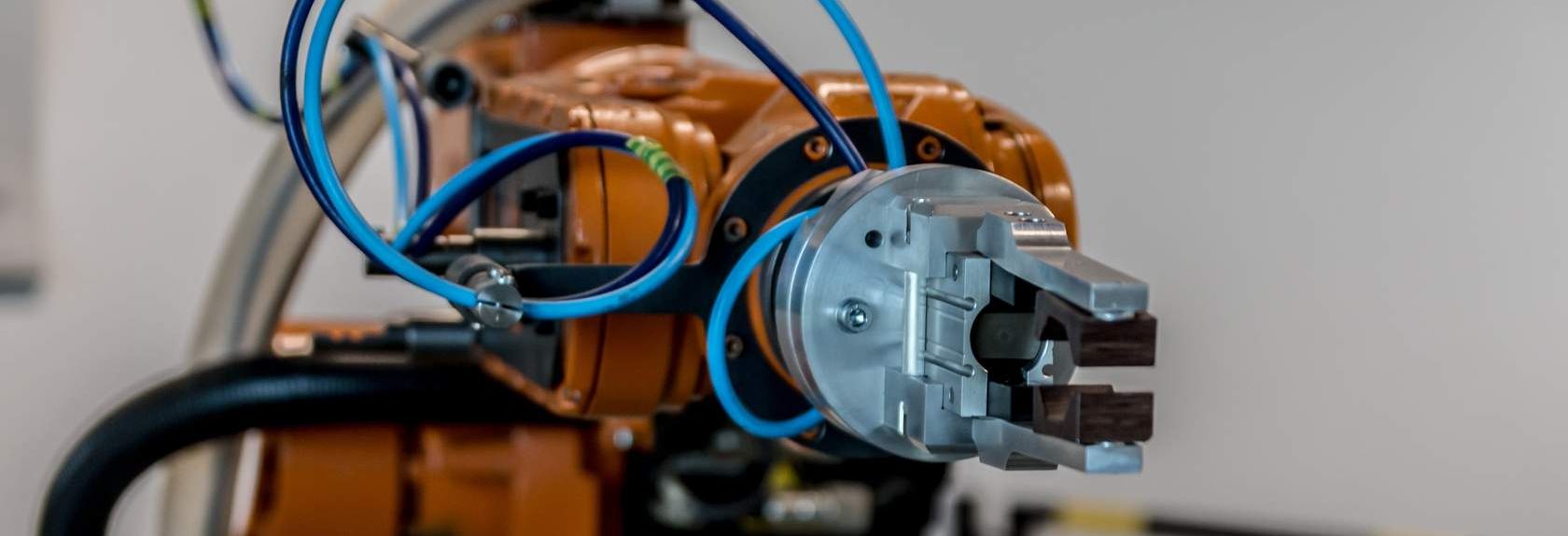

Articulated robots

The most common industrial robots, these look like human arms and are also called robotic arms or manipulator arm robots. Articulations with several degrees of freedom enable articulated arms to make a wide range of movements. Articulated robots are typically used for materials handling, welding and assembly tasks.

Cartesian Coordinate robots

Also called rectilinear, gantry robots, and x-y-z robots, they have three primary control axes that are all linear (move in a straight line rather than rotate) and are at right angles to each other. The three sliding joints correspond to moving the wrist up-down, in-out, back-forth. These robots can be used for plotting graphs, 3D printing, overhead gantry loading and unloading, milling router holes, and in pick-and-place machines for heavy loads.

Cylindrical Coordinate robots

Characterised by their rotary joint at the base and at least one prismatic joint connecting its links, these robots can move vertically and horizontally by sliding. The compact effector design allows the robot to reach tight workspaces without any loss of speed. Uses include spot welding, grinding, injection moulding, machine handling (e.g. die-cast machines), assembly operations, palletising, as well as loading and unloading.

Spherical Coordinate robots

These robots only have rotary joints and are one of the first robots to have been used in industrial applications. They are commonly used for Pressure Die Casting (PDC) machine tending, plastic injection and extrusion moulding, as well as welding.

SCARA robots

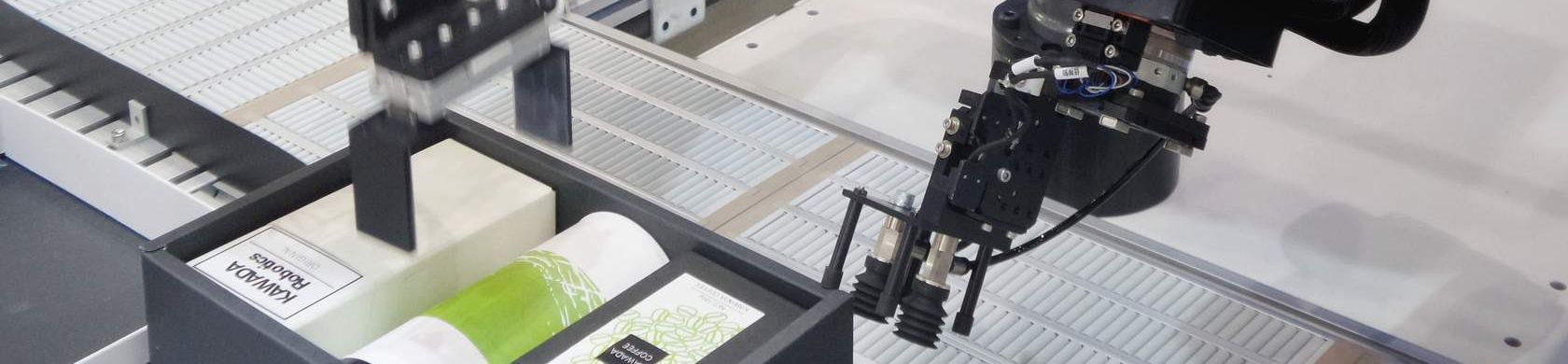

Selective Compliance Assembly Robot Arm (SCARA) robots are characterised by their two parallel joints, which provide movement in the X-Y plane, but remain rigid in the Z-direction (referred to as Selective Compliance). They are commonly used for pick-and-place or assembly operations, where high speed and high accuracy are required. Generally, these robots can operate at a higher speed than Cartesian Coordinate robots.

Delta robots

A type of parallel robot. These robots consist of three arms connected to universal joints at the base. The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector. Delta robots are often deployed for picking and packaging in factories as they can be very fast, some capable of executing up to 300 picks per minute.

Virtual commissioning of an industrial robotics system uses an automation simulation environment, rather than the physical robotics system, to test the behaviour of the system and the control software. Digital Twin can be used for the planning, testing and validation of a product using simulation tools. Permanent tracing of all production data from the real product, as well as identifying any problems during development and manufacture of the product, is also possible.

The Digital Twin is a software representation of a physical robotic system, including its components and the processes used to understand, predict and optimise the physical robot’s performance. The Digital Twin consists of three components: a data model, a set of analytics or algorithms and knowledge. Using Digital Twin technology provides an efficient method of optimising a cyber-physical system prior to on-site installation and commissioning.

Watch the video below to see an example of Digital Twin systems at CSIRO.

The full article or CSIRO's Mixed Reality Lab can be seen here:

https://blog.csiro.au/reality-check-digital-twin-tech-to-transform-manufacturing/

Watch the video below to see an example of a Digital Twin system for Victoria.

More can be details about Victoria's Digital Twin project can be found here:

https://www.land.vic.gov.au/maps-and-spatial/projects-and-programs/digital-twin-victoria

Features of Digital Twin Software

The main features of Digital Twin Software include:

- advanced form of simulation software that can support simple applications like programming joint control;

- plane detection can be used to place the Digital Twin model image on virtual horizontal surfaces to match the real robotic model (physical twin);

- synchronous representation of a physical twin with its digital twin can be used to compare movements;

- direct feedback for monitoring live data such as current and temperature can be used;

- capability to assist in online/remote programming the physical twin using technology akin to that used in a gaming platform, making it possible to directly teach the physical robot new movements in a shorter time than in more traditional programming methods;

- image target feature allows the operator to visually overlay the digital twin over the physical twin;

- simulated movements of the physical twin in the real world are possible using the digital twin model in augmented reality; and

- clear visualisation of real-time process data can be used to test the physical twin’s performance.

Installing and commissioning a robotics system onsite involves the following stages:

Stage 1. Planning

- Design the robot work cell area.

- Identify safety procedures to be followed.

- Determine the required specifications for installation and operation.

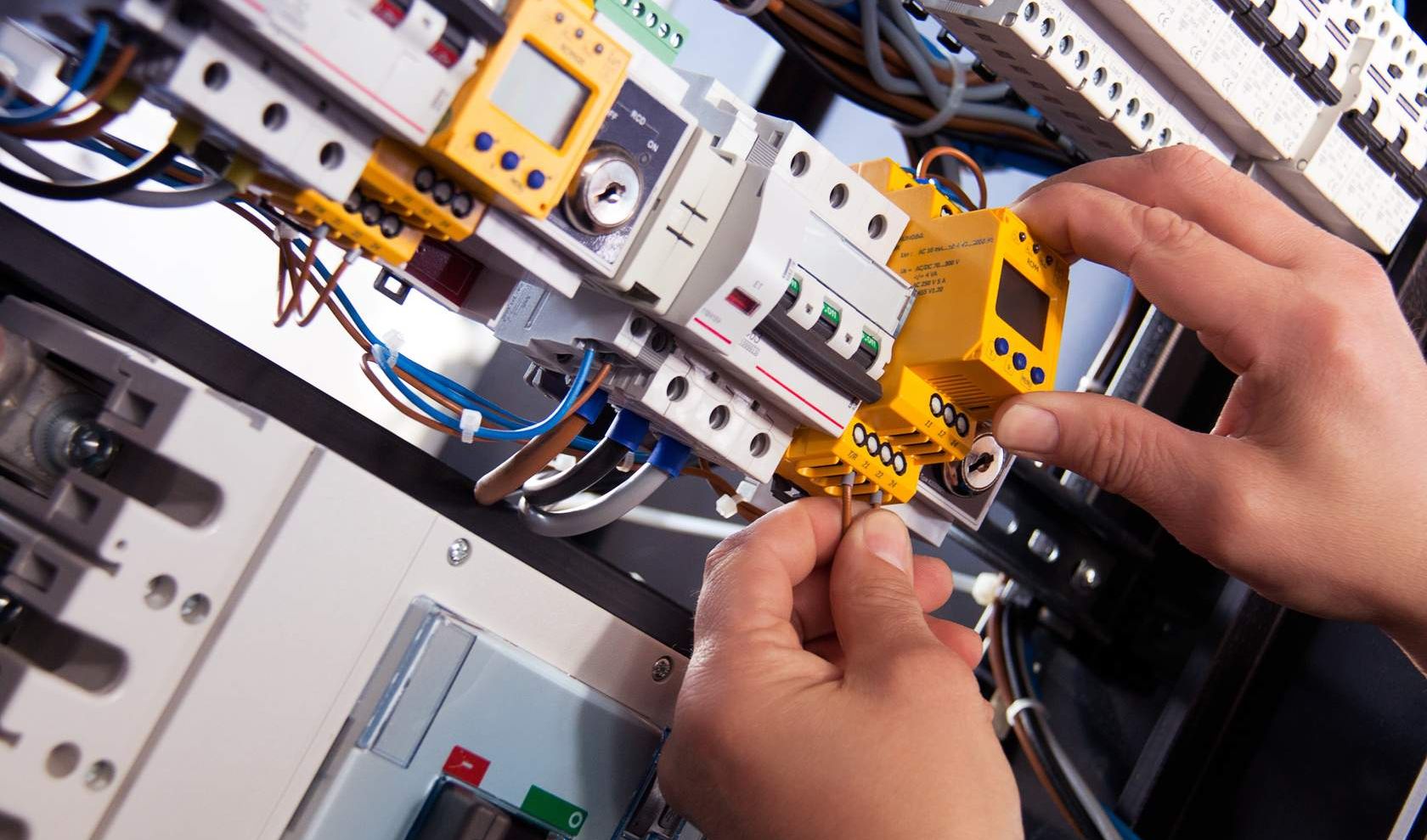

Stage 2. Installation

- Adjust the robotic system specifications according to those planned.

- Determine the safety requirements of the robot in the on-site operating environment, such as the floor pad and work area cage required.

- Integrate interface sensors and peripherals with the on-site production processes and ancillary automation.

Stage 3. Operation and Interfacing

- Optimise the programming operation and settings for the site.

- Check sensor and peripheral interfacing are functioning effectively.

Stage 4. Testing

- Test and adjust sensors and peripherals to ensure functional integration with the robotics system.

- Fully test the robotics system performance and fine-tune to ensure the newly installed system meets on-site specifications.

- Complete and report on commissioning activities.

The uptake of industrial robotics systems has greatly increased as technological developments have rapidly advanced and become adapted to expand current system capabilities. Industry 4.0 technologies have revolutionised production processes, and with Industry 5.0 technologies said to be on the horizon, the use of artificial intelligence (AI) to augment existing systems and further developments in materials and electronics, this trend is expected to continue.

Learn about industries utilising robotic systems:

- Manufacturing

- Construction

- Medical and pharmaceutical

- Packaging and distribution

- Transport

- Farming

- Fabrication

Manufacturing Applications

In the manufacturing industry over the past few decades, industrial robotics systems have generally made production lines more effective, adaptable and exact. Robots can be used as an alternative for manual labour tasks and, when equipped with appropriate sensors, can perform routine inspection tasks.

Learn about manufacturing applications:

- Sheet metal fabrication

- Motor vehicle assembly

- Food factory production lines

- Inspection of product batches

- Handling heavy parts or tools

- Repetitive movements for automated assembly

- Processing tasks, such as welding, spray painting, routing, grinding and polishing

There are many examples of manufacturing applications at the Swinburne-CSIRO National Industry 4.0 Testlab for Composite Additive Manufacturing in Clayton.

Explore the Testlab below using a virtual walkthrough.

Insert video here.

More details about the Testlab can be found here:

https://www.swinburne.edu.au/research/platforms-initiatives/industry-4-0-testlab

Industrial robotics systems technology offers advantages for the construction industry. Robotics applications are being used to automate building processes and increase productivity, with the capacity to complete tasks faster with more precise detail and at less cost than more traditional methods.

Select the heading below to learn about construction industry applications.

- Automated manufacturing – allows more efficient component production, material handling and packing.

- Automated processes - welding, dispensing, painting, cutting and finishing jobs can be done faster.

- Architectural plans – efficiently drawn and customised to client specifications, can be completed accurately in less time.

- 3D printed items - tools and components can be created quickly and cheaply, with the possibility of deployment on-site, as in customised air ducting.

- Demolition tasks – breaking down walls, crushing concrete and site clean-up can be completed by robots.

- Brick laying – construction workers can feed bricks into a brick laying machine that lays the bricks according to instructions from CAD software to greatly speed up the brick laying process.

Watch the video below to learn about how Swinburne uses robotic systems in simulating construction techniques at the Smart Structures Laboratory.

Insert video here.

Medical and Pharmaceutical Applications

A diverse range of robots have been developed for a variety of medical applications and this trend is expected to continue as new technologies become available.

Pharmaceutical applications for the efficient production and packaging of medicines and health care aids have also taken advantage of continuing developments in technology. Robotics can also play a vital role in pharmaceutical research and development.

Select the heading below to learn about pharmaceutical industry applications.

- Surgical assistants - robotics can be used in minimally invasive surgeries, such as orthopaedic, neurologic and laparoscopic procedures. A robotic arm can be manipulated to perform procedures using operating controls and screens with advanced 3DHD technology and gives surgeons the spatial references needed for highly complex surgeries using enhanced stereo visualisation.

- Rehabilitation - assistive and therapeutic robots can assist patients with serious medical conditions such as stroke or who need rehabilitation therapy for physical trauma injuries sustained from an accident.

- Remote specialist consults – can be made by GPs in remote areas using technology to help treat patients who would otherwise need to travel long distances. Video links can also be set up for assistance with complex surgeries.

- Sanitising and disinfecting robots – now important with an increase in antibiotic resistant bacteria and outbreaks of deadly infections, these robots can efficiently and effectively clean and disinfect surfaces in medical facilities.

- Pharmaceutical R&D - robotics can assist in research and development by speeding up the drug discovery process and supporting the speedy development of new vaccines.

- Drug production – robotics is important in the manufacture of pharmaceutical drugs, as pharmaceutical production processes demand high speed and accuracy. Robotics is also key to accurate and reliable packaging and distribution processes

- Pharmaceutical devices – devices such as syringes, inhalers, IV bags and diabetes testing kits can be made accurately and efficiently with the assistance of robotics

Watch the video below to learn about a robot system for Photobiomodulation of Chronic Pain.

Insert activity here.

Even now, some manufacturing robotics systems utilise a hybrid system of factory robots collaborating with human workers. Future robotics systems could be enhanced with artificial intelligence and potentially lead to more widespread adoption of advanced manufacturing processes. As the technology gets smarter, more efficient, intelligent and cheaper, robots will become more commonly utilised to perform more complicated operations.

As robotics systems become cost-effective and automated robotic tasks are simplified, many companies that currently make use of robotic tools are likely to expand the use of robots in their production systems. Emerging technologies have the potential to simplify robot programming, and advances in voice-recognition technology could make it possible to give robots verbal directives. It may also be possible for robots to operate with a higher level of flexibility with developments in artificial intelligence, sensors and human-robot interface technologies.

The future is expected to hold great potential for fully automated Smart Factories that use combinations of next-generation automation and production, artificial intelligence, robotics and machine learning.

Watch the following video to learn about Swinburne's Factory of the Future presented in a fun AR animation below.

Insert activity here.

Summary

This module looked at the many types of robotic systems available to industry, small businesses and even the public. The advantages and disadvantages of robotics systems used in industry were explored, as well as optimising a robotics system using Digital Twin and commissioning a robotics system on-site.

The main categories of industry that currently employ industrial robotics systems were covered, including the manufacturing, construction, medical and pharmaceutical industries. Take the knowledge check below to test your understanding of this module.

Knowledge Check

Insert activity here.

Below are some links to find out more about Robotics.

Watch the following video to learn about Robotics and Mechatronics Engineering at Swinburne.

Insert video here.

Links:

- Study Robotics and Mechatronics Engineering at Swinburne:

https://www.swinburne.edu.au/study/course/bachelor-of-engineering-honours/robotics-and-mechatronics/ - Swinburne's Intelligent Robotics program:

https://www.swinburne.edu.au/research/institutes/manufacturing-futures/intelligent-robotics/ - Rehabilitation research by Dr Chris McCarthy at Swinburne:

https://www.swinburne.edu.au/news/2016/04/robots-can-help-young-patients-engage-in-rehab/ - Record breaking Rubik's Cube-solving robot developed by students at Swinburne:

https://commons.swinburne.edu.au/items/b8da1d36-9552-4188-b2ff-5a10d32574b5/1/ - Robot-assisted laparoscopic surgery - an ergonomic investigation, Swinburne:

https://commons.swinburne.edu.au/items/46b55a52-6d05-40f6-869b-75af0a937c89/1/ - CSIRO - Robotics and autonomous systems:

https://data61.csiro.au/en/Our-Research/Focus-Areas/Robotics-and-Autonomous-Systems