Advanced manufacturing incorporates a range of innovative digital technologies, processes and practices that industry can use to improve the productivity and competitiveness of manufacturing operations.

Industry 4.0 digital technologies applied in advanced manufacturing include:

- Robotics and automation

- Sensor technology and data analytics

- Artificial intelligence (AI) and machine learning.

Watch the following video to learn about CSIRO's Manufacturing for Australia.

Advanced manufacturing uses systems of innovative technologies to automate manufacturing processes fully or almost fully to increase productivity, efficiency and product quality. Information management, computation, software control, sensing and network communication are tightly integrated to automate production processes in an advanced manufacturing system.

Some innovative technologies used in advanced manufacturing:

- Additive manufacturing

- Composite materials

- Robotics and automation

- Welding and laser machining

- Nanotechnology.

Watch the following video to learn about the Siemens launch of MindSphere at Swinburne University, a system that integrates technologies across manufacturing processes.

Advanced manufacturing systems are particularly suited to manufacturing industries requiring complex technological manufacturing solutions. Click the + below to view a list of advanced manufacturing applications that have been adopted by various industries.

Select the heading below to learn about advanced manufacturing applications.

- Aerospace

- Automotive

- Aviation parts

- Processed foods

- Steel buildings

- Medical devices

- Pharmaceuticals

- Robotics

- Rapid prototyping.

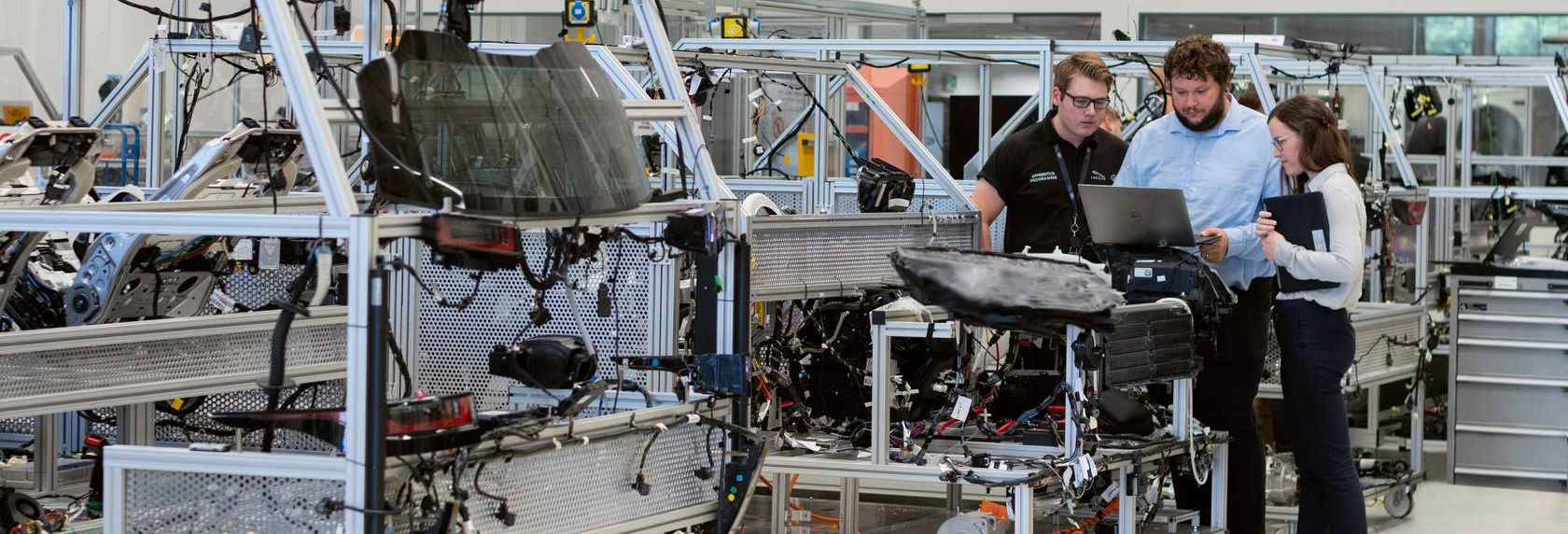

The automotive industry uses car prototypes to trial styling and user interface ideas, as well as manufacturing techniques, advanced materials, engineering concepts and much more.

Industrial robotics in the food manufacturing industry are increasingly being used to automate manufacturing methods, despite slow initial uptake. Food manufacturing processes have been more difficult to automate due to the need for more precise robotic manipulative control.

Processing food at high volume has required developments in robotics to accommodate handling food of variable size and texture, as well as being able to handle delicate foods that could be damaged during manufacture, packaging and distribution. Vacuum grippers combined with better robotic visualisation software have made it possible to adapt robots more readily for the food manufacturing industry.

Industrial robotics and automation systems are also being used for pick-and-pack processes, as well as food distribution networks.

Watch the following video to view an example of an advanced pick-and-pack process using AI control systems in the food industry.

CAD and CAM refer to the two types of software used for designing products and manufacturing prototypes, finished products and customised products.

When we show up to the present moment with all of our senses, we invite the world to fill us with joy. The pains of the past are behind us. The future has yet to unfold. But the now is full of beauty simply waiting for our attention.

Learn about CAD and CAM.

Computer-Aided Design

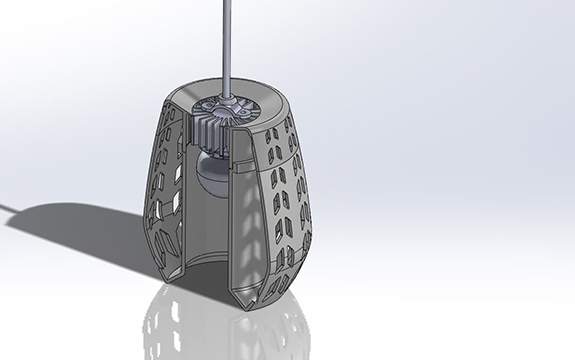

Computer-aided design (CAD) involves the use of computer software to assist in creating engineering design drawings. Designs can then be analysed, modified and optimised before proceeding to manufacturing. Both 2D and 3D model designs can be produced using CAD software.

CAD software can improve design quality and allow for rapid and accurate design adjustments. Standardised design documentation for manufacturing purposes and patent applications can also be readily created. CAD software files are used for print, machining and other operations required for manufacturing a wide variety of parts and products.

Computer-Aided Manufacturing

Computer-aided manufacturing (CAM) involves the use of software to control machine tools used in the manufacturing process. Examples of machine tools typically used in CAM systems include turning, 5-axis turning, laser/plasma cutting, waterjet and electrical discharge machining (EDM).

Watch the following video that demonstrates the use of CAD and CAM in the manufacturing process.

Additive manufacturing refers to the use of 3D printing to build parts or products from layers of material laid down horizontally, according to specifications determined in a prototype 3D design. Industries with the highest rate of 3D printing technology adoption in 2020 were biotechnology, transportation and automotive manufacturing.

Lower costs and higher precision using additive manufacturing have been particularly useful in biotechnology applications, such as the manufacture of prosthetic hands. 3D bioprinting using stem cells has also been utilised to create replacement heart valves. The costs involved in producing high volumes of metal parts in advanced manufacturing systems are extremely high compared to costs for more traditional manufacturing processes, such as casting and moulding. Replacing metal only materials with composite materials, such as combining aluminium, nylon and carbon fibre, could eventually bring costs down for some products and improve finished material characteristics.

Artificial Intelligence (AI) technology has the potential to advance industrial, medical and materials design. AI and machine learning accelerate the design process, utilising pattern recognition to speed up data analysis and detect defective units during assembly. Products are also more readily optimised or customised as needed during manufacture.

Watch the following video about Anatomics, an advanced manufacturing company based in Melbourne, highlighting the use of additive 3D printing with titanium for medical prosthetics.

The Industry 4.0 Testlab in Composite Additive Manufacturing is a new facility located at the CSIRO Clayton site in partnership with Swinburne. Construction is due to be completed in October 2022. This facility is expected to put Swinburne and CSIRO at the forefront of manufacturing digitalisation.

Swinburne University of Technology, Industry 4.0 Testlab:

https://www.swinburne.edu.au/research/platforms-initiatives/industry-4-0-testlab

CSIRO, describes the Testlab collaboration with Swinburne:

https://www.csiro.au/en/work-with-us/services/research-and-development/Prototyping/Testlab

Advanced Manufacturing techniques and engineering technologies are being used to manufacture parts for the aerospace industry. The space industry has seen substantial benefits from the application of Industry 4.0 technologies. Aerospace manufacturing facilities are using a collaboration platform approach to manufacturing large complex undertakings, integrated with a cyber-physical system production model.

Cyber-physical systems manage the production of all parts and components for large manufacturing projects, such as new composite materials, customised parts and specialised aircraft. The materials, tools, machines and people involved across the project are coordinated to facilitate agile development, faster market delivery times and increased productivity.

The Australian Government has a number of national policies and initiatives with the goal of growing the Australian economy and improving the country’s industry capabilities. One of these initiatives is to support a globally recognised Australian space sector. This sector will have the capability, capacity and expertise to locally design, develop, manufacture and deploy specialised products, equipment, systems and services for export to international markets and to support national and international space missions. View the following links for more details:

- Space National Manufacturing Priority road map:

https://www.industry.gov.au/data-and-publications/space-national-manufacturing-priority-road-map/road-map-at-a-glance - Rocketing Aussie space manufacturing into the future:

https://www.minister.industry.gov.au/ministers/taylor/media-releases/rocketing-aussie-space-manufacturing-future

Australian Space Manufacturing Network

Swinburne University of Technology is the Victorian lead university in an Australian consortium of space manufacturers and industry partners that have been awarded $52 million in Federal Government co-funding as part of the Modern Manufacturing Initiative – Collaboration scheme.

As the lead Victorian university in the $157 million Australian Space Manufacturing Network, Swinburne will play an important role in connecting Victorian industry partners to the advanced manufacturing national supply chain. The project will help secure Australia’s share of the global space economy, which is expected to grow to $1 trillion by 2040.

View the following link for more details: https://www.swinburne.edu.au/news/2022/03/52-million-boost-to-supercharged-australian-space-manufacturing-network/

Matthew Shaw is researching at Swinburne on how to overcome the harsh conditions in space to extract building material from Moon rocks. Engineering PhD student and ‘extractive metallurgist’ Matthew Shaw won the Asia Pacifc 2021 Three Minute Thesis (3MT) competition.

Watch the following video submission from Matthew Shaw's (3MT 2021 Competition).

Insert activity here.

The full article on Matthew Shaw's thesis can be read here:

https://www.swinburne.edu.au/news/2021/08/Swinburnes-three-minute-thesis-winner-explores-space-contruction/

Summary

This module explored the advantages of advanced manufacturing systems and how a range of innovative digital technologies, processes and practices can be incorporated to automate manufacturing processes fully or almost fully to increase productivity, efficiency and product quality. The integration of several types of Industry 4.0 technologies to create complex advanced manufacturing systems was covered, with some applications highlighted in more detail.

The future of advanced manufacturing is important to growing a country’s economy and knowledge of emerging technological developments is vital in the modern world. Take the knowledge check below to test your understanding of this module.

Knowledge Check

Insert activity here.

The Aerostructures Innovation Research (AIR) Hub, is a research and industry collaboration. Swinburne is developing the next generation of aerostructures for use in civil aviation, eVTOLs, UAS, AAM and space.

Watch the following video to learn more.

Insert video here.

Below are some links to find out more about Advanced Manufacturing.

Links:

- The Aerostructures Innovation Research (AIR) Hub, Swinburne:

https://www.swinburne.edu.au/research/platforms-initiatives/air-hub/ - Manufacturing Futures Research Institute, Swinburne

https://www.swinburne.edu.au/research/institutes/manufacturing-futures/ - ManufacturingTech, CSIRO

https://research.csiro.au/robotics/our-work/solutions/manufacturing/ - Advanced Manufacturing in the State of Victoria

https://djpr.vic.gov.au/about-us/overview/strategies-and-initiatives/advancing-victorian-manufacturing