During Course 4 you will gain knowledge about the characteristics and applications of electrical cords and cables. This includes physical attributes such as construction, insulation, size and colour. Also included is cable selection based on external factors such as moisture, temperature and mechanical damage and internal factors like current carrying capacity and voltage drop. Sample calculations are given for selecting cables. Work through these carefully, making sure you understand where all the figures have come from.

Moving on from cable identification and selection, you will learn how to install and connect them to appliances. You will meet different classes of appliances, common cable support systems and most importantly - inspection and testing techniques. It is also helpful to know about moisture and fire barrier ratings for electric cable penetrations since you will be installing wiring systems in a variety of building materials.

Throughout the course you will be referring to AS/NZS 3000 and other relevant regulations. Some of the exercises require you to search the Wiring Rules for correct information. It is essential to select and install electrical cables according to the proper guidelines so make sure you complete these exercises – this is great practice for when you are working in the industry.

The final section of Course 4 looks at basic lighting principles and luminaire installations. Examples are given of how to plan a simple lighting layout and you will be expected to complete a plan of your own.

The course will involve a lot more practical work than previously. Take note of the cables, tools and installations in the workshop. Practice the techniques your tutor demonstrates such as stripping wires, terminating cords and cables using crimp lugs, installing a plug top and making up and testing cord extension sets.

Have fun!!!

| Day One | Day Two | Day Three | Day Four | |

|---|---|---|---|---|

| Course Content | Electrical cables, cords and cables, circular and flat cables. | Describe construction and configuration of common cables. | Describe flexible cord insulation colours. | Cable insulation types. |

| Self-directed Learning | Comparing flat and circular cables. | Minimum bending radius. | Thermoplastic and thermosetting materials. | Complete your research on cable insulation. |

In order for you to gain the most value from your qualification and to prepare you for your assessment and the industry, make sure you complete all of the online and SDL tasks.

What we're covering:

- electrical cables

- cords

- circular and flat cables

Legislation

- Before we begin it is important to be familiar with and to comply with the relevant legislation for this section. The selection and installation of wiring systems must be performed according to the:

- Electricity (Safety) Regulations 2010.

- Health and Safety at Work Act 2015.

- AS/NZS 3000:2018, Electrical installations (known as the Australian/New Zealand Wiring Rules), including Amendment 1.

Which section of the Wiring Rules outlines the requirements for the selection and installation of wiring systems?

- AS/NZS 3008.1.2:2017 Electrical installations – Selection of cables – Cables for alternating voltages up to and including 0.6/1 kV (at 50 Hz) – Typical NZ conditions (nominal ambient air and soil temperatures are 30°C and 15°C, respectively).

Cords and cables

Cords and cables both transmit electrical power.

AS/NZS 3000 1.4.20 defines a flexible cable as – “A cable; the conductors, insulation and covering of which afford flexibility.”

AS/NZS 3000 1.4.36 defines a flexible cord is defined as a flexible cable in which:

- The individual wire strands are smaller than 0.31mm diameter.

- No conductor exceeds 4mm2 cross-sectional area. (Once the CSA exceeds 4mm2 it is referred to as a flexible cable.)

- The sheathing contains no more than 5 cores.

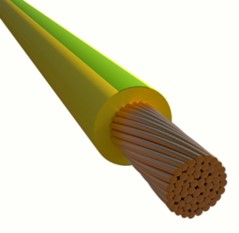

A flexible cord consists of very small individual strands of copper wire, making up a flexible conductor core which is then insulated. Each core in the cord is the same size.

- Up to 5 cores are combined and a sheath of insulation is put around the outside.

- The thickness of the sheath determines the ‘duty’ type of the cord, i.e., light duty, ordinary duty or heavy duty.

- The most common types of flexible cord used for portable electrical appliances, range in size from 0.75 mm2 to 1.5 mm2 with two or three sheathed cores.

The wire ‘size’ is the cross-sectional area of the wire, which is the area of the circular cross-section of the wire, in mm². If a flexible cord has a total cross-sectional area (CSA) of 0.75 mm2, it would be referred to as 0.75 mm2 flex.

For circular cross sectional area conductors, use π r2 to calculate cross sectional area.

Cords may also be described by the number of strands and diameter of each strand in each core. A common type of 0.75 mm2 flexible cord could be referred to as 24/0.20 (24 strands, each 0.2mm in diameter).

Try out the maths! The cross-section area of bunched wires can be calculated as:

A = n d2 π /4

where: n = number of wires and d = single wire diameter (mm)

Note – Cables above 1 mm2 must have stranded conductors according to NZACP 51:2004.

Exercise 1

Check your understanding by answering the questions in the worksheet about cables before proceeding. Email your answers to your tutor.

Circular cables and flat cables

The cable system is expected to last the life of the equipment, so it is important to choose cable that maximises durability and longevity, while meeting other requirements. Flat and round cables have significant design differences that make them suited to different applications.

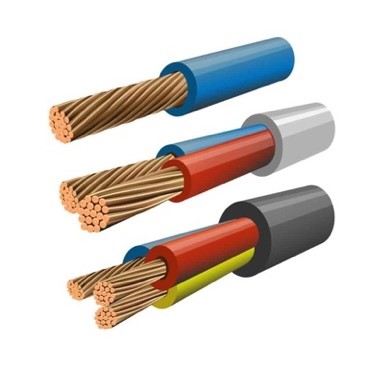

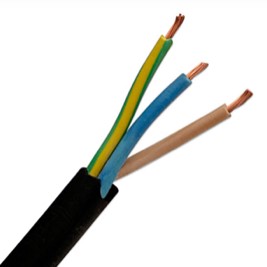

Circular Cables

Round or circular cables contain one or more conductors, covered with insulation and packed with protective material giving the cable a rounded, cylindrical shape.

Although less flexible than flat cables, round cables can bend along any axis, making them suitable for applications that require extensive bending and twisting in long cable runs, especially raceways or conduits.

Round cables are also more suited to applications requiring protection against environmental factors such as:

- Rail transportation – harsh weather and constant motion.

- Material handling – heavy loads and vibrations.

- Waste processing operations – wet environment with heavy-duty moving parts.

- Power distribution systems in high-rise buildings such as office buildings, hotels, hospitals, shopping malls, etc.

- Lighting systems for highways, bridges, and tunnels.

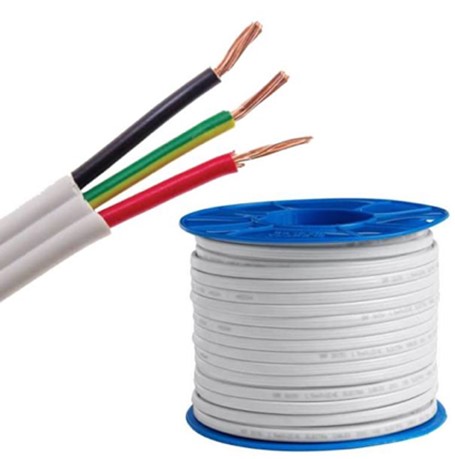

Flat Cables

As the name suggests, these cables have a flatter design. Conductors are individually encapsulated, carefully arranged in a straight line at precise intervals and surrounded by insulation. Unlike round cables, flat cables do not usually have layers of fillers and shielding, making them relatively compact and lightweight, making them less prone to wiring errors and cheaper to manufacture.

Flat cable wire bends easily in only two directions, making them best suited for rolling flex, since this movement is in one linear axis.

The heat dissipation of flat cables is superior to round cables because of their higher surface-area-to-volume ratio. Consequently, flat cables handle higher temperature rise and current levels per conductor cross-section.

Flat cables are suited to applications requiring flexibility or with tighter space requirements. They save on installation space and cost, and their bending radius is smaller than that of round cables with the same number of core wires.

Their applications include:

- Robotics applications involving highly complex designs in very tiny spaces.

- Telecommunications - for navigating cramped areas and saving space.

- Overhead cranes with space limitations and the necessity of continual flexing.

- Lifting equipment, cable tracks, trolleys, transmission machinery, elevators, telescopic machinery, and other mobile electrical power transmission lines and control, lighting, communication channels in special places, and they can also be used in enclosed indoor environments.

Self-directed Learning

Complete the table in this worksheet comparing flat and circular cables. (The first feature has been done for you.)

What we're covering:

- construction and configuration

- TPS cables

An electrical cable is used for the transmission and distribution of electrical energy. Circular cables consist of the following parts:

- Conductor(s): channel the flow of electricity and are made from either plain or tinned copper, or solid or stranded aluminium. Solid conductors consist of a single piece of metal wire, while stranded conductors are composed of several thinner wires twisted into a bundle. The bundled strands can be configured into a variety of geometric arrangements to meet specific design requirements for any device or application.

- Insulation: covers the conductor to prevent current leakage. The two main types of insulators are thermoplastics (e.g., polyvinyl chloride, PVC), and thermosetting plastics (butyl rubber, ethylene propylene).

- Auxiliary elements: protect the cable and extend its lifespan. Includes metal shields (screens) to isolate signals that pass through the interior of the cable from possible external interference; mechanical armour to protect the cable against damage and in some cases provide earthing; a fill layer surrounding the conductors to maintain the circular cross-section. These will vary depending on the situation the cable will be used for. (More on this later.)

- Outer sheath: provides external mechanical protection against damage from moisture, corrosion, dirt, sun, temperature, fire, external aggression etc.

Exercise 2

Complete the following table by matching these three common stranded wire arrangements of conductors, to their correct description and diagram.

*Note - concentrically laid cables can be bundled in several ways, decreasing their overall size. For a compressed concentric layout, the conductor is assembled and pulled through a die to bring the strands closer together, whereas a compact concentric layout shapes the strands into trapezoids before being bundled together to remove as much empty space as possible.

A size comparison is shown here:

Manufacturer's information

Cable manufacturers provide information about their cables such as operating voltages, temperature ratings and conductor type and size. Further cable specifications, such as those below, can be found in the manufacturer’s technical data publications:

- Overall cable dimensions.

- Resistance to direct sunlight, UV, chemicals, water, and fire

- Weight of cable per unit of length

- Mechanical properties of insulating materials.

- Chemicals released when combusted

- Application

- Approvals

- Installation conditions.

Different manufacturer’s specification tables vary in detail, so it is important that you use the appropriate tables for the cable you are using. Two examples can be found here of specifications for Flat TPS cable. Read these, focusing on the information provided in each case.

Exercise 3

Find 3 similarities and 3 differences for the two TPS cables and list these in the table provided in this worksheet.

Self-directed Learning

- Cable manufacturers will often include the Minimum Bending Radius for cables in the specifications. (Refer to the Prismian cable example.) Research this term.

- Look up the term Minimum Bending Radius and explain on a piece of paper why it is important in cable selection. You should bring your findings to class and discuss with your tutor.

What we're covering:

- cord colours

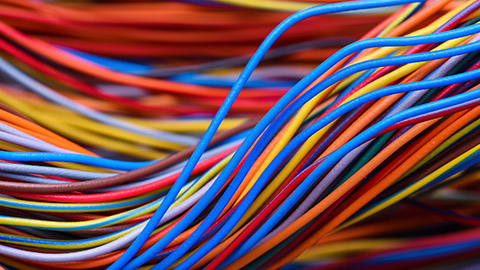

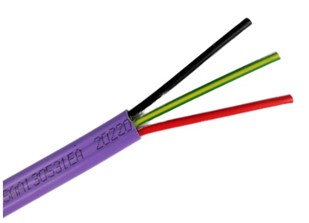

You must follow the correct wiring colour codes during installations. Refer to Section 3.8 of the AS/NZS 3000:2018 which specifies the correct conductor colours to be used for installation wiring.

For electrical safety, the wiring colour codes for AC and DC wires, as well as single phase and three phase systems, are critical. Compliance not only saves you time by ensuring easy maintenance and troubleshooting; it protects those who are working on, or coming in contact with, the installation.

You are probably aware that every country has its own electrical code for cable and wire installation and electricity distribution. The US and Canada follow the NEC “National Electrical Codes” and most of Europe, including the UK, follow the IEC “International Electrotechnical Commission” codes. Extra care must be taken when connecting imported equipment that does not use AS/NZS conductor colours!

In New Zealand we follow the Australia & New Zealand Wiring Colour Codes for single phase and three phase power circuits. The live wire is brown, the neutral is blue, and the earth is green and yellow. Because wire colour codes have changed throughout time, this may not be the case for every electrical system – you may come across earlier systems that have different colours.

These updated conductor installation colours for flexible cords, flexible cables and equipment wiring are now in keeping with typical European (IEC) practices.

The comparison of conductor insulation colours of multiphase cables manufactured to current AS/NZS Standards, as well as equipment manufactured to typical European practices, is shown below:

Note

When flexible cords or cables are used for installation wiring purposes (not extension or appliance cords), black and light blue are not to be used as active conductors.

Exercise 4

Recap – match the wire to its correct colour and role.

Exercise 5

Refer to AS/NZS 3000:2018 Section 3.8 to answer the questions on this worksheet.

Self-directed Learning

Cable insulation materials may be categorised as either Thermoplastic or Thermosetting. Research the important characteristics of each material and how these affect their insulating properties.

- Thermoplastic materials are…

- The advantage(s) of using thermoplastic insulation is…

- Two examples of thermoplastic insulators are…

- Thermoset materials are…

- The advantage(s) of using thermoset insulation is…

- Two examples of thermoset insulators are…

What we're covering:

- TPS cables - flat and circular

The NZECP 51:2004 Section 3 Table 2 provides guidelines for selecting and installing cables. Namely - Tough plastic sheathed (TPS) cable must be used for both the mains cable and installation wiring, while polyvinyl chloride (PVC) insulated conduit wire must be used for main earth or main equipotential wiring in NZ.

Tough Plastic Sheathed Cable

TPS cable consists of an outer sheath of PVC insulation (usually white for flat TPS and black for circular TPS) and one or more inner coloured thermoplastic sheaths enclosing a copper core or cores - either single or multistrand. It is double insulated since are two layers of insulation material protecting the conductors.

Flat TPS is used for fixed wiring where there is less chance of mechanical damage e.g., lighting, power outlets, appliances, and heating, ventilation and air conditioning (HVAC) units. It is available in several conductor configurations: single, twin, twin and earth, three and earth, and four and earth (the latter two are used for three-phase supply). ‘2 + E’ is the quick way to write twin and earth cable wire.

For instance, the typical wiring requirements of a range/oven are:

- minimum 2 + 6mm2 TPS cable

- protection by a 32-40A MCB in the distribution board.

Circular TPS cable is suitable for fixed installation in industrial installations. It has a hard PVC sheath making it more robust than flat TPS and easier to run.

Flat cables have greater surface-to-volume ratio than their round cable counterparts, consequently having higher efficiency in dissipating heat. This allows a higher current level for a given temperature rise and conductor cross-section.

Standard V-75 or V-90 TPS, (with maximum operating temperatures of 75°C and 90°C respectively), should not be used below 0°C as the insulation becomes brittle and will shatter. These cables must also be protected from external influences such as UV radiation, chemicals, or oils.

Contact with some building materials such as polystyrene, polyurethane, and bituminised building papers may also damage PVC insulation. To avoid this problem either use a cable with a migration-resistant plasticiser as shown here or prevent the cable contacting the material altogether.

Conduit wire refers to single core insulated cables without a sheath. It comes in a range of sizes and is often used for wiring in enclosures such as internal switchboard wiring.

Conduit wire is often installed with extra protection, such as conduit*, since the conductor is only protected by a single layer of polyvinylchloride (PVC) insulation.

*An electrical conduit is a tube in which electrical wires are housed for added protection. When wire is to be installed in conduit, there may be restrictions due to size, temperature, explosion considerations and other factors.

Exercise 6

Research the following types of cable insulation. In each case provide a brief description of the material; its insulating properties; and its application. You can write your ideas on this worksheet.

Self-directed Learning

- Complete your research on types of cable insulation.

- When you are next in the workshop identify some of the different cables present, taking note of their appearance and composition.