Week 6

| Day One | Day Two | Day Three | Day Four | |

|---|---|---|---|---|

| Course Content | Recommissioning electrical equipment. Key safety checks, functional checks and restoring power. | Scenario - Outline steps to decommission, then recommission a conveyor belt. | Capstone Revision – tutor to provide previous exams and manage online discussion and questions. | Capstone Revision – tutor to provide previous exams and manage online discussion and questions. |

| Self-directed Learning | Videos recommissioning electrical fittings & systems. | Complete questions and study for Capstone Exam | Capstone Revision | Capstone Revision |

In order for you to gain the most value from your qualification and to prepare you for your assessment and the industry, make sure you complete all of the SDL tasks.

What we're covering:

- Recommissioning electrical equipment.

- Key safety checks, functional checks and restoring power.

Recommissioning electrical fittings and systems means restoring, testing, and confirming that electrical equipment, devices, and systems are in good working order. Safety is paramount during the recommissioning process due to the risks of electrocution, fire, property damage, legal compliance, and worker well-being.

Key safety checks

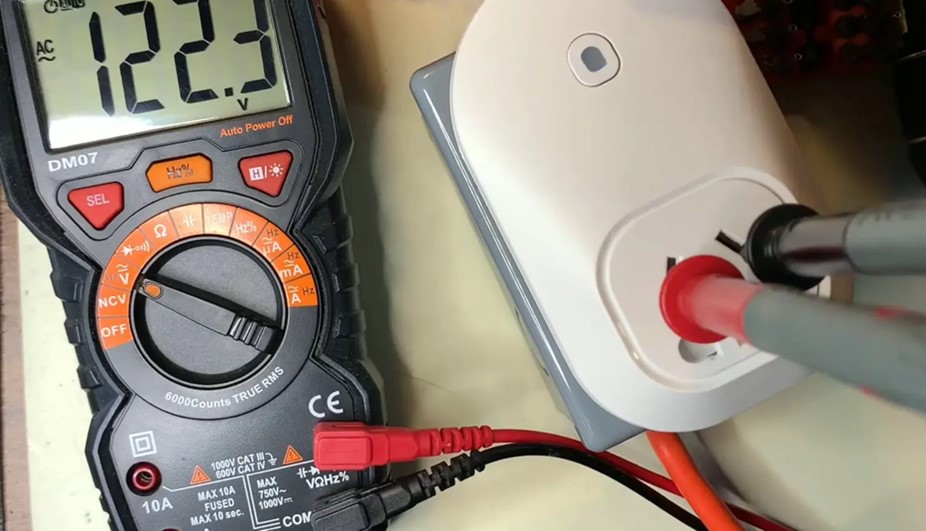

The key safety tests to perform before recommissioning fittings and systems include:

- Visual/Mechanical Inspection: Conduct a thorough visual inspection of the entire electrical system, including the overall mechanical state of the equipment, the proper connection of earth continuity conductors and neutral conductors to their respective bars, the completion of earth bonding for extraneous metal parts in line with AS/NZS 3000 guidelines, identification of broken components and conductor supports, and checking for loose terminations of conductors.

Additionally, the examination involves identifying stray conductor strands, burnt or damaged conductor insulation, assessing the effectiveness of flexible cord or cable anchorage, ensuring proper labelling of switches and protective devices, evaluating the condition and rating of internal fuses, overload devices, overheating devices, internal switches, and indicator lamps, and confirming the correct fitting of protective screens and guards. - Earth Continuity Test: This test ensures that the earth (ground) connection is intact and provides a low-resistance path for fault currents. It involves checking the continuity between the equipment's metallic parts and the earth connection.

To conduct the test, the exposed metal parts of the electrical equipment are checked against either the earth pin of its plug or the earth bar. The primary goal is to demonstrate an unbroken and low-resistance route to earth from any exposed metal or earth termination points. This examination is carried out with an ohmmeter set to the low ohm scale to capture very low resistance values. The connection between exposed metalwork and the earth pin of a three-pin plug should not exceed 1 ohm in resistance. Similarly, fixed wired earth continuity conductors must have a low enough resistance to trigger the protective device in the appropriate timeframe, ensuring the safety of the system. - Insulation Resistance Test: This test evaluates the soundness of the insulation within the electrical system. It involves applying a high voltage between the conductors and the ground to measure the resistance. A high resistance indicates good insulation.

For the system to pass, the insulation resistance must be equal to or greater than 1 megohm. However, before conducting these tests, it's essential to ensure satisfactory earthing. It's crucial to exercise caution when dealing with electrical systems containing semi-conductor components, as many of these components can't withstand the higher voltage of an insulation resistance tester and could break down irreparably. When testing such systems, certain precautions need to be taken, such as disconnecting semi-conductor components or testing between specific pairs and the electrical appliance framework. - Polarity and Connections Check: During the recommissioning process, ensuring correct polarity and connections is necessary to prevent potential hazards and incorrect setups.

This testing involves preventing combinations like incorrect phase, neutral, and earthing conductors, connections that could electrify exposed conductive parts of the system, and incorrect connection of switches or protective devices leading to energised components when switches are off. It also covers scenarios like unpredictable operation of multi-phase equipment and semiconductor-controlled devices, current-carrying protective earthing conductors, and any short circuits. If the equipment is powered by a flexible cord, the test also includes verifying the correct polarity of cord and plug pins

Exercise 32

Functional testing and restoring power

After finishing all the tests and confirming that the plant, equipment, or appliance is safe, the next step is to check if it works correctly.

- As each worker is done and leaves, they remove their locks and tags. This goes on until all locks are off, and then the plant can be turned back on.

- During the functional test, ensure switches, circuit breakers, and protective devices are doing their job properly. This might mean trying out some fault situations to see if the safety mechanisms react as they should.

- Double-check that circuit breakers or fuses are the right size to protect the wiring and equipment from overcurrent situations.

- Ensure that all electrical components are properly labelled and identified. This includes circuit breakers, switches, outlets, and control panels. Clear labelling helps prevent confusion and aids in emergency situations.

- If possible, energize the system in stages, checking for any abnormalities or unexpected responses before fully commissioning it.

- Review and update documentation, including schematics, diagrams, and maintenance records. Accurate documentation aids in troubleshooting and future maintenance.

- The final step is to secure certification for the plant or appliances. Appliances should be certified as safe following AS/NZS 5762 guidelines. This entails meeting the electrical test standards of AS/NZS 3760 and other requirements specified in AS/NZS 5762. For hardwired plant, it must be tested in alignment with AS/NZS 3000, and when required, a Certificate of Compliance and/or an Electrical Safety Certificate should be issued.

Exercise 33

Self-directed Learning

Watch the following videos which cover aspects for recommissioning electrical fittings and systems.

- How To Isolate 230v and Prove Test Prove

- How To Verify New Installation and Test MEN Switchboard

- How To Polarity Test (Complete)

Spend time doing Capstone Exam Revision.

What we're covering:

- Scenario - Outline steps to decommission, then recommission a conveyor belt.

In this scenario you are an electrical technician working in a busy industrial factory that operates around the clock. Today, you have been assigned the task of decommissioning a critical conveyor belt system that transports unfinished components between different processing stations.

The conveyor belt has been experiencing intermittent issues that have affected its performance, causing delays and production losses. To address these concerns, the decision has been made to temporarily decommission the conveyor belt for thorough inspection, maintenance, and potential repairs.

Exercise 34

For each heading below explain the steps you would take, then answer the questions following.

Questions

Self-directed Learning

Capstone Exam Revision

What we're covering:

- Capstone assessment revision

The Capstone assessment is a requirement for all learners undertaking study in Electrical Trade qualifications. It is a paper-based exam that covers knowledge of legislation, and electrical theory and its application. The types of questions in the assessment include:

- multi-choice answer

- short answer

- calculations

Your tutor will cover the assessment conditions and time allowed to complete the assessment in class with you.

Use this time to review your learning from modules 1 through to 7 in preparation for the exam.

What we're covering:

- Capstone assessment revision