Week 1

Welcome to the final course of your Electrical Pre-Trade journey. Course Seven begins by focusing on the tools of the trade. You'll learn how to pick the right tools and gear up safely with Personal Protective Equipment (PPE) for various tasks. We'll cover the hand and power tools commonly used in electrical work, along with their maintenance and potential hazards. Emphasis will also be placed on the right PPE and safety measures when working with power tools.

Moving forward, you'll learn about fault finding in live circuits – a crucial skill for any electrician. You will learn to diagnose electrical faults, recognizing their signs, and understanding what causes them. Plus, you'll get a clear picture of the importance of solid cable connections and terminations. You'll find out about the right tools to measure continuity, resistance, insulation resistance, voltage, current, and RCD performance.

Working in damp environments requires special considerations. We'll study the requirements for damp zones outlined in AS/NZS 3000. You'll get familiar with the ins and outs of electrical protection and IP ratings, making informed decisions about fitting and equipment suitability in damp conditions, ensuring you understand how to create safe spaces where water and electricity coexist.

The course wraps up by guiding you through decommissioning and commissioning processes, along with safe appliance connections. You'll know exactly what testing is necessary before circuits are energised or appliances are put to use.

As you near the finish line of this journey, you will sit the capstone assessment. This is where all your learning comes together to showcase your newfound skills and knowledge. So, get ready to roll up your sleeves and dive into the practical aspects of being an electrician. This final course will equip you with the hands-on skills and know-how you need to step confidently into the world of electrical work.

| Day One | Day Two | Day Three | Day Four | |

|---|---|---|---|---|

| Course Content | Introduction. Hand tools – wire strippers, insulated screwdrivers. | Hand tools – insulated pliers, cable cutters, spanners, safety knife. | Hand tools – hacksaws, hex keys, claw hammer, chisels, torch, crimps, etc. | Power tools – drills (impact, hammer, joist & stud, Hole Hawg, rotary hammer), drill bits. |

| Self-directed Learning | Insulated tools investigation – A4 poster | Insulated tools investigation – A4 poster | Measuring skills quiz. | Power drill quiz and numeracy challenge. |

In order for you to gain the most value from your qualification and to prepare you for your assessment and the industry, make sure you complete all of the SDL tasks.

What we're covering:

- Hand tools – wire strippers, insulated screwdrivers

When you're on the job, your tool kit becomes your best friend. It's what helps you apply your skills and make sure everything is safe and reliable. Without the right tools, electrical work just can't be done properly. Tools may be categorised as:

The following is a list of must-have tools for your toolbox. These tools will help you do your job effectively, whether you're installing new systems, fixing problems, or doing regular maintenance.

Hand tools

A hand tool is any tool that is powered by hand without motor. On a piece of paper, list all the hand tools an electrician might use on a daily basis.

Wire strippers

Electricians use wire strippers to cut through the protective sheath of cables to access the conductive core. The stripping process ensures that only the necessary amount of pressure is applied to prevent damage to the copper wires.

Proper wire strippers speed up the job, make it easier to work with wires, and result in neater connections between wires, and terminals or connectors.

Types of Wire Strippers:

- Adjustable Strippers - Versatile tools that can handle stripping, crimping, and wire-snipping tasks.

- Triple Action Wire Strippers - Designed for thicker cables with tough insulation, utilizing a unique spiral cutting motion.

- Wire Stripper Pliers - Suitable for thicker, multicore cables, featuring V-shaped stripping jaws.

- Sheath Strippers - Utilize a rotary action to produce a neat ring cut while stripping.

- Pistol Wire Strippers - Have a self-adjusting blade and use a compound stripping action with a firm grip.

- Automatic Wire Strippers - Use a mechanism to rapidly remove insulation and cut wire with a single application of pressure.

- Manual Wire Strippers - Standard hand-operated models usually with a spring-loaded handle and safety lock.

Wire strippers are also referred to as cable strippers or cable wire strippers. Some wire strippers are capable of handling twin and earth cables, which enhances their versatility.

Exercise 1

Below are some questions relating to wire strippers. Email your answers to your tutor.

- What is the purpose of using wire strippers in electrical work?

- Describe the function of 'Triple Action Wire Strippers'.

- You need a thicker multicore cable for an electrical project. Which type of wire stripper would you chose and why?

- In what situations would 'Automatic Wire Strippers' be particularly advantageous?

Insulated screwdrivers

Screwdrivers are a fundamental and indispensable tool for electricians due to their versatility and precision. Electricians use screwdrivers to access electrical containers, install and remove electrical components, make wiring connections, adjust devices, and perform repair and maintenance work. They are crucial for mounting fixtures and devices, accessing electrical panels, and ensuring proper grounding and bonding.

The operation of screwdrivers relies on the application of torque, which is rotational force, exerted when the screwdriver's head is inserted into the slot on the screw.

Electrician's screwdrivers feature carefully designed insulated handles, ensuring protective electrical resistance. These insulated handles are crucial to safeguard electricians against potential electrical hazards while working with live electrical components. The VDE approval indicates compliance with safety standards for electrical applications.

Safety is crucial, necessitating that all screwdrivers are insulated up to 1000V to protect against electrical shock and arcing.

Screwdrivers come in various sizes and shapes, offering compatibility with the wide range of screw designs encountered in electrical work. Driver tips are the key point of differentiation.

Amongst the most prominent are:

- Slotted Screwdrivers - have a single, flat blade that fits into straight-line slots on screws. They are commonly used in older electrical equipment and various general applications.

- Phillips screwdrivers - have a cross-shaped tip with four arms, designed to prevent over-tightening. They are widely used in electrical work, electronic devices, and other applications.

- Pozidriv screwdrivers - have a similar cross-shaped tip like Phillips, but with additional notches for improved torque transmission. They are commonly found in modern electrical appliances, industrial equipment, and certain construction materials.

Exercise 2

Self-directed Learning

This SDL task will carry over to Lesson 2.

Your task is to investigate insulated tools and their significance, especially in electrical work. Follow the steps below to understand what insulated tools are, why they're essential, and how they enhance safety.

Present your findings as an A4 poster and post on the class forum.

Introduction to Insulated Tools

Begin by searching for a simple definition of insulated tools. Understand the basic concept of how these tools are designed to keep workers safe during electrical tasks.

Safety and Prevention

Explore the importance of using insulated tools for safety. Learn how they prevent electric shocks and accidents by acting as a barrier between you and the electricity.

Types of Insulated Tools

Identify a few common types of insulated tools used by professionals. Focus on tools that electricians and other professionals use when working around electricity.

Benefits of Insulated Tools

Discover the advantages of using insulated tools. Look for benefits such as protection against electric shocks and the safeguarding of equipment.

Task Using Insulated Tools

Research how to correctly use insulated tools. Find any guidelines or tips that help you ensure your safety and the tool's effectiveness.

Real Life Examples

Look for any real-life stories or examples where insulated tools have made a difference. These stories will give you practical insights into the impact of using these tools.

Conclusion

Reflect on what you've learned and think about how this knowledge can be applied to future tasks and situations involving electrical work.

What we're covering:

- Hand tools – insulated pliers, cable cutters, spanners, safety knife.

This lesson on hand tools continues from the previous lesson.

Insulated pliers

Pliers have been used for a long time due to their ability to accomplish tasks that require torque more effectively than bare hands alone. Modern pliers are typically made from steel, providing a robust grip and ensuring durability in challenging work environments.

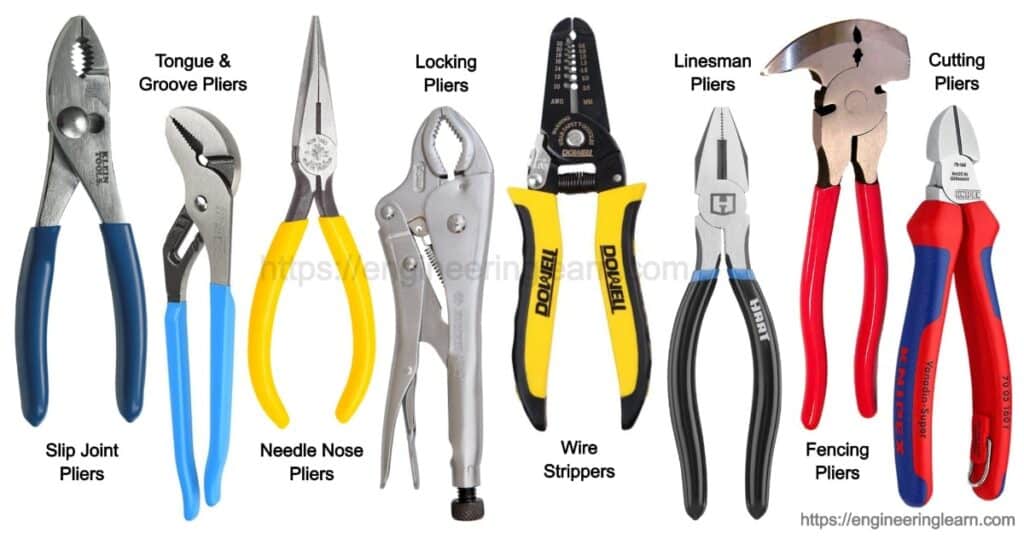

Different types of pliers are available - each designed for specialised tasks. Some types of pliers used in the electrical workplace include:

- Combination Pliers - Multifunctional tools for cutting wires, stripping insulation, and gripping, replacing the need for multiple tools.

- Long Nose or Needle Nose Pliers - Essential for delicate electrical tasks, gripping small objects, and accessing tight spaces.

- Slip Joint Pliers - Adjustable jaw span, ideal for nuts, bolts, and fasteners for a secure grip. (Slip joint pliers are also referred to as Pump, Tongue-and-Groove, Channel Lock, or Adjustable Pliers.)

- Side Cutting Pliers - Designed for easy and precise wire cutting in tight areas and electrical boxes.

- Locking Pliers - Securely lock onto objects for a strong grip, useful for metalwork.

- Terminal Crimping Pliers - Create secure and reliable crimp connections for electrical terminals and connectors.

Insulated pliers are essential for performing a wide range of fiddly electrical tasks, especially when dealing with wires. The insulation provides protection against electrical shocks, ensuring the safety of the electricians. Buy high-quality insulated pliers from reputable brands to ensure durability and reliability during electrical work.

Exercise 3

Cable cutters

Cable cutters, also known as wire cutters, are heavy-duty pliers designed specifically for cutting thick cables and wires cleanly and efficiently. Their sharp blades provide clean and precise cuts through various types of cables and wires. Consider the cutting capacity of the cable cutter, which ranges from 0.4mm to 600mm, ensuring it meets the requirements of the job.

Cable cutters used in electrical applications are typically insulated to prevent electrical shocks. (Fully insulated cable cutters are essential when working with high-voltage wiring.) It is important not to confuse the plastic or rubber coating on the levers of a non-insulated cable cutter for being electrical insulation.

Cable cutters don’t just cut cable, they also bend, hold, twist, or strip small gauge wires and are made to be very precise. They provide a handy way to strip off insulation for crimping and similar operations quickly.

Spanners

Spanners are among the most useful and versatile tools in an electrical toolkit. Besides handling nuts and bolts, they can be used as clamps, grips, or even levers when needed. Their multi-functional nature makes them indispensable for various tasks encountered in electrical work.

Proper selection and use of spanners are crucial for safe and effective electrical work. Different sizes of bolts and nuts require various spanner designs to ensure a close fit between the head which applies torque and the fixture in question. Size is equally important in order to achieve a tight grip.

Common spanner models:

- Adjustable spanner - Features a moveable jaw that can be adjusted to fit different sized bolts or nuts. Often referred to as a monkey wrench, it offers versatility in handling various fasteners. A must-have tool for dealing with different sizes of nuts and bolts during electrical installations and repairs.

- Open Ended Spanner - Consists of a double C-shaped clamp in different sizes at either end. Ideal for situations where space is limited, allowing easy access to fasteners in confined spaces. Useful for tightening or loosening nuts and bolts found in electrical panels and equipment.

Tips:

- Ensure you have spanners in different sizes to handle various fasteners encountered in electrical installations.

- Use the spanner at the correct angle and avoid excessive force to prevent damage to the fasteners or the tool itself.

- Regularly clean and maintain spanners to prolong their lifespan and maintain their effectiveness.

Exercise 4

Answer the following questions and email your tutor with your responses.

- What is the purpose of using an adjustable spanner?

- How does an open-ended spanner differ from an adjustable spanner?

- Imagine you needed to work on a nut located in a tight place within an electrical panel. Which type of spanner would you choose and why?

- Why is it important to regularly clean and maintain your spanners?

Safety Knife

As an electrician, wire cutting is a common task, making a sharp utility knife an essential addition to your toolbox. Safety knives with smaller blades make it easier to cut wires securely. Safety knives are known by various names: Stanley knives, utility knives, pen knives, or box cutters.

The key feature is that the knife blade is shielded for safety when not in use, minimising accidents and injuries. Some models have spring-loaded sliders that automatically retract the blade after use.

Safety knives come in different shapes and sizes for various situations. Professional safety knives for electricians have handles made from aluminium, plastic, or steel. The blade material can be stainless steel, carbon steel, or tool steel for maximum cutting power. The blades in safety knives are often replaceable when broken or dulled, and some utility knives feature snap-off blades that offer a fresh cutting edge when needed.

Safety is crucial when using a safety knife. The small and movable surface of wires increases the risk of blade slipping.

Exercise 5

Make a list of precautions you should take when using a safety knife.

Self-directed Learning

Complete working on your investigation of insulated tools started in the previous lesson.

What we're covering:

- Hand tools – hacksaws, hex keys, claw hammer, chisels, torch, crimps, etc.

This lesson continues the learning started in the previous two lesson.

Hacksaws

A hacksaw is a type of hand tool designed for cutting through various materials, including plastic, steel, and other metals. It features fine-toothed saws, enabling clean and precise cuts in metal. Electricians often rely on hacksaws to cut metal conduits and pipes during installation and repairs, and they also prove useful for trimming electrical boxes and brackets when needed.

The hacksaw features a thin, flexible blade held at tension in an adjustable frame connected to a pistol grip handle, ensuring a comfortable and firm grip during cutting tasks. The blade's tension can be easily adjusted to suit various cutting requirements. The blades are replaceable when they become dull or broken, providing convenience and efficiency in the tool's maintenance.

Hacksaws are produced in a variety of shapes and sizes to support a range of applications and industries. In New Zealand, hacksaws are available in both metric and imperial sizes. The main types of hacksaws include:

- Senior hacksaws or full-sized hacksaw - large, versatile tools that are straightforward to operate and excel at cutting tougher materials.

- Junior hacksaws - a smaller saw used when space is limited, or more precise cutting is required. They feature softer, half-sized blades and are not suitable for cutting harder substances. Junior hacksaws are compact, easily portable hand tools.

Exercise 6

When using a hack saw for cutting tasks as an electrician, what safety precautions should you take to ensure your well-being and prevent potential hazards? (Describe a minimum of five.)

Email your answers to your tutor.

Hex keys

Hex keys, also known as Allen keys or Allen wrenches, get their name from the hexagonal fasteners they adjust. They come in various materials like steel, nickel, bronze, or copper alloys.

Types of Hex Keys include:

- Straight Hex Keys - Used as extensions to screwdrivers, they apply torque to hexagonal fastenings.

- L-Shaped Keys - Have identical heads at both ends, offering different leverage. The shorter end provides more leverage, while the longer end allows access to confined spaces.

- Folding Hex Keys - Convenient and easily stored due to their folding design.

- T-Handle Hex Keys - Feature ergonomic handles for a firmer grip and improved control.

Hex keys are essential when working with hexagonal fasteners and fixings in various electrical devices and equipment. Some handy tips are:

- Always use the correct size of hex key to avoid damaging fasteners and to ensure a secure fit during adjustments.

- Keep hex keys in a well-organised toolbox to prevent misplacing or losing them.

- When using hex keys, make sure to apply steady and even pressure to avoid stripping or rounding the fastener edges.

- Regularly inspect hex keys for signs of wear and replace them if they become damaged or worn out.

- Familiarise yourself with the different types of hex keys and their specific applications to work efficiently and safely in electrical installations and repairs.

Claw Hammers

Claw hammers are versatile tools used by electricians and other tradespeople. One side of the hammer features a standard head for driving nails and inserting fixtures. The other side of the hammer has a dual steel claw designed to provide a robust grip, making it easy to remove nails and similar fixtures.

Claw hammers are useful to gain access to sealed spaces, such as fuse boxes hidden behind paneling or other fixtures.

Some handy tips to consider are:

- When using a claw hammer, ensure proper technique and precision to avoid accidents and damage to the materials.

- Maintain the hammer's claws in good condition by regularly checking for wear and sharpening or replacing them when needed.

- A comfortable and ergonomic handle is crucial to reduce strain and fatigue during prolonged use.

- Keep the hammer clean and dry to prevent rust and corrosion, which can affect its performance.

- Always wear appropriate personal protective equipment, such as safety glasses and gloves, when using a claw hammer to prevent injuries.

- While it's not necessary to invest in the most expensive make or model of claw hammer, it is important to choose a high-quality hammer that can perform the job effectively and safely. Choose the one that best suits your needs and preferences as an electrical worker.

Chisels

Chisels are powerful and versatile tools used for breaking through various materials like wood, stone, brick, concrete, and others. Despite their ancient origins, chisels remain essential and effective in modern times for various applications. Modern chisels are typically made from various steel alloys, providing durability and strength.

Electricians often use chisels to create channels in walls for running electrical cables, conduits, and other wiring, making them a valuable tool during installation procedures. Popular sizes of chisels to keep in your tool kit as an electrical apprentice include 5mm, 10mm, 16mm, 18mm, 20mm, and 50mm.

- When using chisels, ensure you have a firm grip and use appropriate striking tools, such as a mallet or hammer, for effective and safe cutting.

- Always wear proper personal protective equipment, like safety glasses and gloves, when using chisels to protect against potential injuries.

- Regularly inspect chisels for signs of wear and maintain their sharpness to ensure efficient cutting performance.

- Store chisels properly in a designated tool holder or toolbox to prevent damage and to keep them easily accessible.

- Familiarise yourself with the different types of chisels available and their specific uses to effectively apply them in electrical installations and repairs.

Torches

Torches are essential items that every electrical worker should have in their tool kit for various situations. Many different torch designs are available, but smaller torches powered by LEDs are typically favored by professionals due to their lightweight and easy portability while providing sufficient illumination.

Torches play a vital role for electricians, allowing them to work in darkened areas, such as buildings where the lighting has failed or when the power is switched off for safety reasons.

Head torches, which can be attached to helmets or hats, are particularly useful when both hands are required for precise work in dark or confined spaces.

Magnetic torches, which can be attached to metal surfaces, provide added convenience and versatility during electrical work.

Handy tips to consider are:

- Ensure torch has sufficient battery power before starting any task to avoid disruptions and potential hazards.

- Always carry spare batteries or a charging source for your torch to avoid unexpected power outages during critical work.

- Regularly check and maintain torches to ensure they function optimally when needed.

- Invest in high-quality torches to ensure durability and reliability in demanding electrical environments.

- Use the torch responsibly and be considerate of others in shared workspaces to avoid disturbing co-workers or causing accidents.

- Properly store torches in your tool kit or designated compartments to prevent damage and ensure they are readily accessible when required.

Crimps

Crimps are small metal connectors used in electrical and electronic applications to join or terminate wires and cables. Crimps are designed to create a secure and reliable electrical connection by being crimped or compressed onto the wires.

Crimps come in various shapes and sizes, depending on the specific application, including butt splices, ring terminals, spade terminals, and more. The appropriate crimp should be selected based on the task requirements.

Properly crimped connections not only provide reliable electrical conductivity but also contribute to the safety and longevity of electrical systems.

Crimping tools, also known as crimpers or crimping pliers, are specialised tools used to apply even and controlled pressure to crimps. Electricians should use crimping tools that match the type and size of the crimps they are working with. Using the correct tool ensures precise and effective crimping, preventing potential issues like loose connections or damage to the wires.

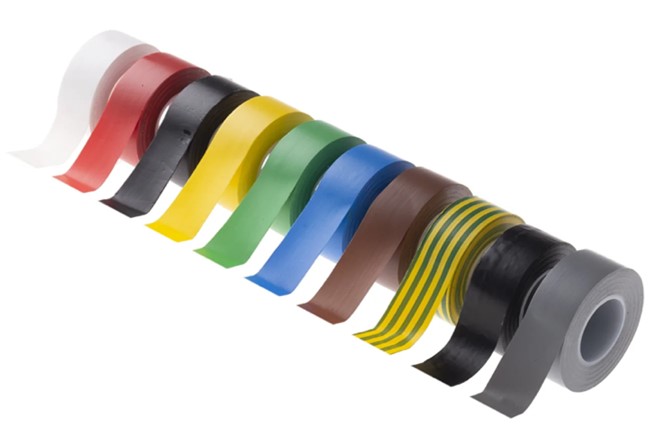

Electrical tape

Electrical tape, also known as insulation tape, is a self-adhesive and pressure-sensitive tape used to insulate wires and other conductive materials. Its primary purpose is to protect the sensitive conducting core within electrical wiring from external elements such as abrasion, heat, liquids, and environmental factors. It helps keep wires organised and secure, reducing the risk of electrical hazards and improving the overall safety of the system.

Electrical tape is made from various materials, including PVC, vinyl, copper foil, and glass cloth. Different varieties offer varying characteristics such as colours, widths, thicknesses, temperature tolerance, adhesion strength, and insulating capabilities.

A high-quality electrical tape should be water and heat-resistant, self-adhesive, and flame-retardant. These features enhance the tape's performance and longevity in various environments. Store your electrical tape in a dry and cool environment to maintain its adhesive properties and prevent deterioration.

While black is the most commonly used colour for general insulation, having a variety of colours in your toolkit is beneficial for differentiating wires and organizing complex wiring systems. Recall the colour-coding system in New Zealand:

- Green/Yellow combination indicates the protective earth or ground wire.

- Green tape alone may be used to signify the protective earth or ground wire, though the green/yellow combination is more common.

- Blue tape is often used to identify neutral conductors in LV applications.

- Red tape is used to mark low-voltage AC (alternating current) conductors.

- Black tape is generally used for general insulation purposes and to indicate the low-voltage neutral point in a circuit.

- Brown tape is used for marking live or phase conductors in single-phase systems.

Torpedo (Spirit) Level

A torpedo (spirit) level is an essential tool when placing conduits, electrical boxes, switches, and other components. It ensures accurate alignment and levelness of these elements, which is crucial for proper installation and a neat, finished result.

Besides levelling tasks, torpedo levels can also be used for determining slopes and angles, making them versatile tools in various electrical applications.

Choose a torpedo level that is easy to hold and use. Comfortable handling is essential when working in tight spaces or overhead positions, allowing you to achieve accurate readings without strain.

Many electricians prefer torpedo levels with magnetic sides as they offer added practicality. The magnetic feature allows you to easily attach the level to metallic surfaces, freeing up your hands for adjustments and ensuring a hands-free levelling experience. Invest in a high-quality torpedo level that can withstand the demands of daily electrical work. Durable materials and construction ensure the tool's longevity and reliable performance.

Regularly inspect and clean your torpedo level to keep it accurate and free from debris. Store it securely in your tool kit to prevent damage and ensure easy accessibility when needed.

Fish Tape

Fish tape, also known as draw wire or ‘electrician’s snake’, is a flexible and flat tool used for pulling wires or cables through conduits, pipes, or walls. Electricians often use fish tape to route and guide electrical wires during installations, especially when working in confined spaces or existing structures.

Fish tapes are typically made of steel or fiberglass and can be coiled or uncoiled as needed for specific tasks. They are usually housed in a retractable coil and can be fed through installed conduit piping.

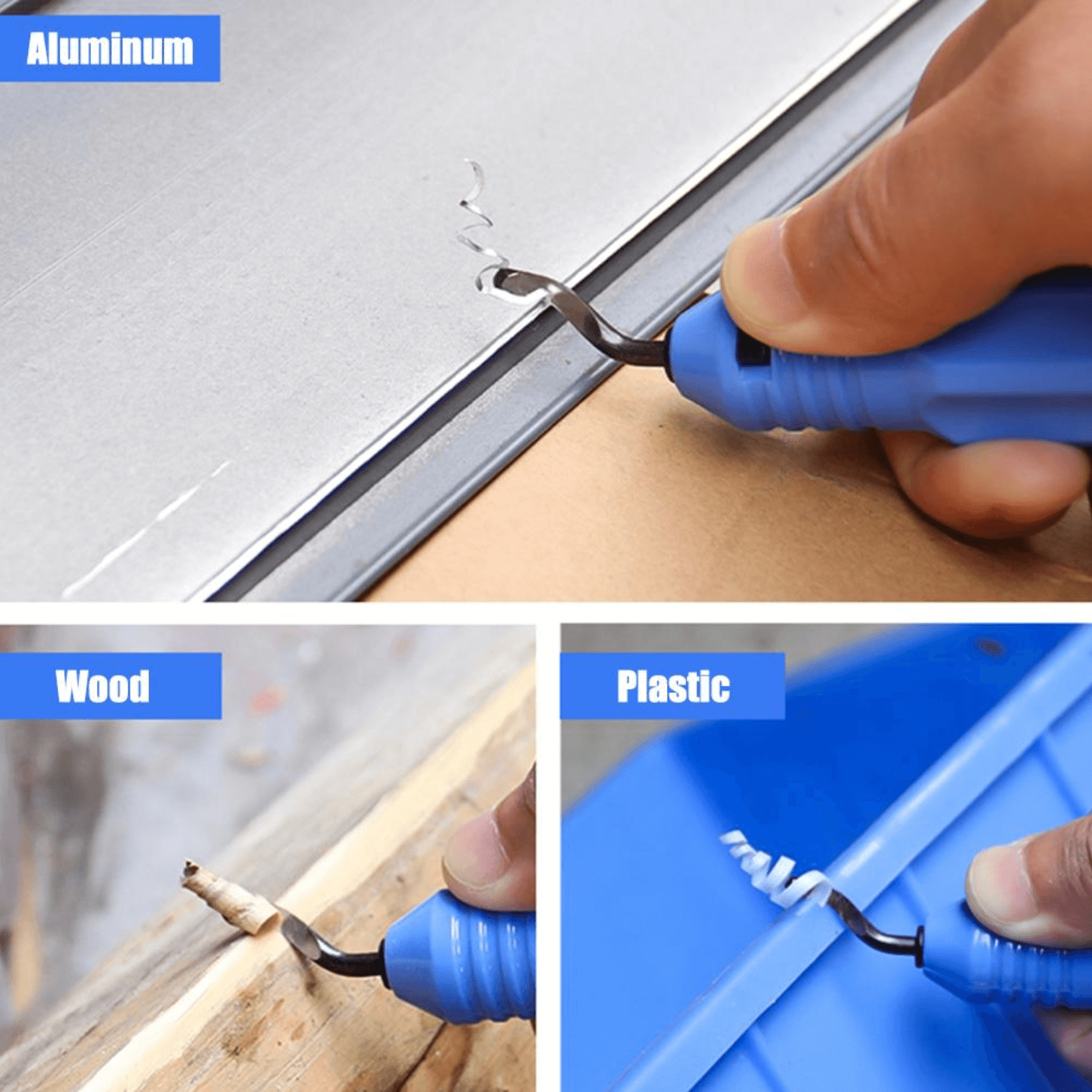

Deburring Tool

Deburring tools are used to remove sharp edges or burrs from the cut ends of pipes, tubes, or other materials after they have been cut. Burrs can be formed during cutting processes and need to be removed to ensure smooth and safe connections.

Deburring tools come in various shapes and sizes, and they are essential for creating clean and precise openings for fittings and connections.

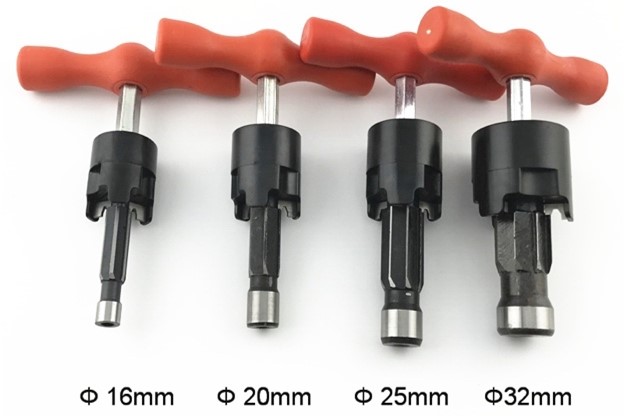

Pipe Reamers

Pipe reamers are tools used to enlarge and shape the end of a pipe or tube to make it suitable for fitting into connectors or other pipe ends. They are often used to remove any irregularities or roughness from the pipe ends, ensuring a proper and secure fit with other pipe components.

Pipe reamers can be hand-operated or powered, and they come in various sizes to match different pipe diameters.

Duct Rods

Rods, or duct rods, are stiff and flexible rods used for cable and wire pulling in underground ducts or conduits. They are commonly made of fiberglass or other sturdy materials. Electricians and telecom technicians use rods to navigate through long and tight cable paths, making it easier to route cables and wires accurately in buried or hidden areas.

Tape Measure

A tape measure is another important item in your toolkit. Electrical installations and repairs require precise measurements for cutting, positioning, and aligning various components. A tape measure ensures accuracy in measurements, leading to efficient and professional-quality work.

Choose a heavy-duty tape measure that can withstand the rigors of daily use in demanding electrical environments. Consider a tape measure with a magnetic tip, as it facilitates one-handed use when measuring metal components or working in tight spaces. A belt clip on the back allows for easy and quick access, keeping the tape measure within reach at all times.

Familiarise yourself with different measuring techniques, such as reading fractions and converting between metric and imperial measurements, to become proficient in using the tape measure effectively.

Watch this video to check your measuring skills.

Self-directed Learning

Check your measuring skills - download this worksheet and complete the tasks. Email your answers to your tutor.

What we're covering:

- Power tools – drills (impact, hammer, joist & stud, Hole Hawg, rotary hammer), drill bits.

Power tools

Watch the following videos which discuss the essential power tools for electricians.

(Be aware some these power tool videos may be sponsored by manufacturers, so focus on learning the tool functionalities and techniques without being influenced too much by brand promotions.)

- Top 7 Power Tools EVERY Electrician Should Have

- 7 Power Tools Every Electrician Needs

- 10 Power Tools ELECTRICIANS SHOULD HAVE

You will need the right power tools to perform your job with accuracy and efficiency. From installing electrical equipment on different surfaces, ranging from soft materials like wood to the toughest ones like concrete, metal, and masonry, to cutting wires and cables, you require a versatile set of corded and cordless tools to get the job done safely and effectively.

Power Drills

A power drill, also known as a standard drill or electric drill, is a versatile handheld tool used for drilling holes in various materials, such as wood, metal, plastic, and masonry. It operates by rotating a drill bit to create holes, and the speed can be adjusted based on the material being drilled.

Power drills are suitable for general drilling tasks and driving screws or fasteners, making them a versatile choice for a wide range of projects. They also used to create holes for running cables, mounting electrical boxes, and attaching fixtures.

Power drills can be corded, requiring a power outlet, or cordless, powered by rechargeable batteries. They come in various sizes and power ratings to suit different tasks.

A cordless drill is a type of power drill that operates on rechargeable batteries, offering greater portability and flexibility compared to corded drills. Cordless drills are widely used by electrical workers for tasks in areas without easy access to power outlets, providing freedom of movement during installations and repairs. Cordless drills may be referred to as battery drills. Stocking up your toolbox with spare batteries and a drill bit set with different sizes is highly recommended.

While drills are versatile tools, a single drill may not be able to handle all the duties you want it to. Different types of drills serve specific purposes and excel in various applications. Here's a summary of what each type of drill is best suited for:

Impact Drill

An impact drill, also known as an impact driver, is a high-torque tool designed to fasten screws into wood, metal, and other materials during installations and repairs. It delivers a lot of rotational force, particularly at low speeds, making it excellent for heavy-duty tasks. They are not typically used for drilling holes.

Impact drills are available in both corded and cordless models, with the cordless versions offering greater mobility. Additionally, impact drills are smaller and more compact than traditional drills, which adds to their portability and ease of use. They also tend to be lighter in weight, reducing user fatigue during extended use.

Hammer Drill

A hammer drill is a powerful tool that combines standard rotary drilling with a forward and backward hammering action, allowing it to drill into stone, concrete, or other masonry more effectively.

Electrical workers use hammer drills for drilling holes into concrete walls, brickwork, and other tough surfaces when installing electrical fixtures. Hammer drills are available in both corded and cordless models.

Combination drill/driver kits

Combination drill/driver kits often come with both a standard drill and an impact driver, which offers versatility for drilling and fastening tasks. With the power drill, you can drill holes in various materials like wood, metal, and plastics, while the impact driver is excellent for driving screws and fasteners with high torque.

The kit is an ideal choice starting out as it covers a wide range of common tasks.

Even with a combination kit, there may still be tasks that require other specialised drills. Having a power drill and an impact driver as part of a combination kit is a good starting point, and then adding a hammer drill or rotary hammer for masonry work and a joist and stud drill for tight spaces can enhance the versatility of the toolset.

Joist and Stud Drill /Right-Angle Drill

A joist and stud drill, also known as a right-angle drill, features a 90-degree angled chuck, allowing it to reach tight spaces and corners that standard drills cannot access easily. It is primarily designed for drilling holes in confined areas, such as between studs, joists, or other obstacles. Electricians use joist and stud drills to drill holes in tight spaces when running electrical cables or conduits through walls or ceilings.

Hole Hawg

A Hole Hawg is a heavy-duty and high-torque drill designed for drilling large holes in wood and other materials. It typically has a two-handed design for added control and stability. Electrical workers commonly use Hole Hawgs for drilling larger holes for conduit installations and cable pass-throughs. These are great when you’ve got 4 or more studs stacked together and you need to drill a hole through all of them to feed a wire through.

Rotary Hammer Drill

A rotary hammer is a heavy-duty tool designed for drilling into hard materials like concrete, stone, and masonry. It uses a piston mechanism to deliver hammer blows in addition to rotation. Electrical workers use rotary hammers for demanding tasks that require drilling large and deep holes in concrete during installations and structural work.

Drivers and Drills

A driver and a drill are handheld power tools with distinct purposes. A driver is designed for driving screws, offering adjustable torque settings and features like LED lights. It uses screwdriver bits in a hexagonal or square chuck. On the other hand, a drill is meant for drilling holes, equipped with adjustable speed settings and a keyless chuck for various drill bits. While drills can drive screws, they lack the torque control of drivers. In essence, a driver is for screws, providing torque control, while a drill is for drilling holes, offering variable speed control.

Drill Bits

You might be surprised how often you need to drill a hole. Ensure you aways have a decent set of twist bits on hand.

Drill bits are tools used to create holes in various materials. They are typically made from high-speed tool steel, which is hard but brittle. To effectively cut into a work surface, the drill bit material needs to be harder than the material being drilled.

There are different types of drill bits to suit various applications and materials. In the electrotechnology industry, some commonly used drill bits include:

Twist Drill

This is the most common type of drill bit. It has spiral-shaped flutes that act as cutting edges and help carry away shavings while providing a path for lubricant to the cutting edge.

The drill also has specific cutting angles, clearance angles, and rake angles.

Auger Bit

Used for drilling into both hard and soft wood, the auger bit features a spiral shape and is effective in creating clean holes.

Spade Bits (Speed Bores)

An alternative to auger bits for wood, spade bits have a flat, paddle-like shape and can cut into hard or soft wood with ease.

Masonry Drill Bits

These bits have tungsten carbide points, which enable them to cut through concrete without losing their shape.

The body of the bit is heat-treated to prevent compression and allow the power drill's hammer action to efficiently transfer energy to the concrete.

Step Drill Bits

Step drill bits, also known as unibits or cone drill bits, are a specialised type of drill bit used for drilling holes in various materials, particularly sheet metals. These bits have a unique design with multiple stepped, conical cutting edges which allows the bit to drill progressively larger holes without the need to change bits or switch to different sizes.

Step drill bits are especially useful when drilling holes in thin materials or when precise hole sizes are required. One significant advantage of this bit is its ability to create smooth, burr-free holes.

Forstner Bits

Forstner bits are often used by electricians for drilling flat-bottomed holes, especially in wood. They are ideal for creating clean, precise holes and are commonly used for installing electrical outlets and switches in wooden surfaces.

Drill bits with a diameter of less than 12.8mm, typically have a parallel shank that allows them to be held in a three-jaw Jacobs chuck on the drilling machine, enabling them to be spun at the appropriate speed and fed into the work surface.

Drill Speeds

Drill speeds are determined by the cutting speed, which refers to the speed at the outside edge of the tool, also known as surface speed. It is measured in meters per minute (m/min). If two tools of different sizes are running at the same revolutions per minute (rpm), the larger tool will have a higher surface speed.

The cutting speed depends on two main factors: the type of material being cut and the type of cutting tool being used. Additionally, the hardness of the work material plays a significant role in determining the recommended cutting speed. Using too high a cutting speed can generate excessive heat and potentially damage the drill bit.

As a general rule, when working with harder materials, it is advisable to use a slower cutting speed. Conversely, when dealing with softer materials, a faster cutting speed can be used to achieve optimal results. Finding the right balance between cutting speed, material hardness, and the type of cutting tool is crucial for efficient and precise drilling operations.

Exercise 7

Self-directed Learning

Review all the information about drills. Complete the quiz and have a go at this question:

Calculate the cutting speed for a drill bit with a diameter of 8mm and a rotational speed of 1200 revolutions per minute (rpm).

The cutting speed formula is:

Cutting Speed (m/min) = π × Diameter (mm) × Rotational Speed (rpm) / 1000.

Ask your tutor to check your answer next time you are in class.