Week 2

| Day One | Day Two | Day Three | Day Four | |

|---|---|---|---|---|

| Course Content | Power tools – electric saws (reciprocating, circular, jigsaw, bandsaw), cordless screwdrivers | Power tools – angle grinders, wall chasers, bench grinders, rotary tool, heat gun. | Meters and testers - multifunction, voltage t, IR, multi-meter, clamp-on ammeter, phase rotation, circuit finders, line locators. AS/NZS 3017:2022 AS/NZS 3760:2022 | Personal Protective Equipment Potential hazards associated with power tool and appropriate PPE. |

| Self-directed Learning | Spending $1500 to create your ultimate toolkit task. | Spending $1500 to create your ultimate toolkit task. | Meters and testers quiz. Spending $1500 to create your ultimate toolkit task. | Matching Power Tool Scenarios, Hazards, and Correct PPE |

In order for you to gain the most value from your qualification and to prepare you for your assessment and the industry, make sure you complete all of the SDL tasks.

What we're covering:

- Power tools – electric saws (reciprocating, circular, jigsaw, bandsaw), cordless screwdrivers

This content continues the learning on power tools that started in the previous session.

Electric Saws

Based on what job you are doing, there are several types of electric saw available, each with specific qualities to help you carry out your tasks efficiently.

Reciprocating Saw

A reciprocating saw, also known as a Sawzall, is a powerful handheld tool with a back-and-forth cutting motion. It is suitable for cutting through various materials, including wood, metal, plastics, and drywall.

Electrical workers use reciprocating saws for demolition work, cutting conduit, removing old fixtures, and making rough cuts when running wires.

Reciprocating saws come in both corded and cordless variants. Cordless models offer more flexibility in tight spaces.

Circular Saw

A circular saw is a versatile handheld power tool equipped with a rotating blade, specifically designed for making straight cuts in materials such as wood, plywood, and MDF. Electric workers find circular saws extremely useful for cutting lumber, plywood, and other materials during construction and installations. These saws are available in both corded and cordless versions, with cordless models being particularly convenient for jobs without access to power outlets.

For those in the construction side of the trade, a circular saw is an indispensable tool. It may not be commonly used by service electricians, but anyone working in a wood-framed environment will greatly benefit from having one. This tool is frequently employed for ripping down studs, crafting scabs, or creating braces for light fixtures. While a Sawzall can serve this purpose as well, when multiple cuts need to be made quickly and efficiently, a circular saw proves to be the superior choice.

Jigsaw

A jigsaw is a versatile power tool equipped with a reciprocating blade that moves up and down, making it ideal for creating curved and intricate cuts in various materials.

Electric workers find jigsaws useful for cutting holes in drywall, making notches for conduits, and fitting electrical boxes into walls.

Jigsaws are available in both corded and cordless models, with the cordless versions offering more manoeuvrability and convenience in situations where access to power outlets may be limited.

Band-saw

Band saws are useful tools due to their efficiency in cutting metal conduit and strut. When electricians frequently deal with cutting metal materials, having a band saw proves more practical than relying solely on a Sawzall for all cutting tasks.

Band saws offer cleaner cuts compared to Sawzall, resulting in neater and more precise work. Another advantage of band saws is the longevity of their blades, which tend to last much longer than Sawzall blades.

Exercise 8

Read the two scenarios following, then answer the accompanying questions. Post them on the class forum and read and comment on what your classmates write.

Scenario 1

You are an electrical worker tasked with installing conduit in a construction site. You need to cut through metal conduit using an electric saw.

- Identify the type of electric saw you would use for cutting metal conduit.

- List three specific safety precautions you should take before using the electric saw.

- Describe how you should position yourself and the conduit while using the saw to ensure safety.

- Explain why it's important to choose the appropriate blade for cutting metal conduit.

Scenario 2

You are working on a residential electrical installation project. You need to create precise holes in drywall to install electrical boxes.

- Which type of electric saw would you choose for this task? Explain your choice.

- List two safety precautions you should take before using the selected electric saw in this scenario.

- Describe how you would ensure accurate and controlled cuts in the drywall.

- Why is it important to wear safety goggles when using an electric saw?

Cordless Screwdrivers

Electric screwdrivers, commonly known as cordless screwdrivers or battery-powered screwdrivers, are designed for driving screws and small fasteners with ease. Electrical workers rely on them for repetitive screw-driving tasks, such as securing electrical components and covers.

These compact and lightweight tools come in various sizes and torque settings, making them suitable for different screw sizes and applications. They can be either corded or cordless, providing flexibility based on the user's needs and preferences.

A high-quality electric screwdriver should be lightweight, anti-shock, and ergonomic, ensuring minimal strain and enhanced productivity during extended use. Safety features are essential to prevent accidents and injuries while handling the tools.

To accommodate different types of screws and materials, electric screwdrivers come with flexible speed ranges. Additionally, they are equipped with LED lights, enabling users to work efficiently in dark and dimly lit areas. For cordless models, fast charging systems are incorporated to minimise downtime and maintain optimal productivity.

Exercise 9

Self-directed Learning

Congratulations! You've just won a $1500 voucher to spend on tools that will kickstart your journey as an electrical worker. Imagine you're going on a shopping spree to create the ultimate toolkit. With this voucher in hand, carefully select the tools you would purchase to best suit your needs as you start out in the electrical field.

Your task is to create a list of tools you would buy with the $1500 voucher. Keep in mind the type of electrical work you plan to pursue (residential, commercial, industrial), the tasks you'll encounter, and the tools that will enhance your efficiency and safety.

For each tool note the:

- Tool Category - List the type/category of the tool.

- Tool Name - Specify the name of the tool.

- Reason for Selection - Explain why you've chosen this tool and how it will be valuable in your work.

- Estimated Cost - Provide an estimated cost for each tool.

- Total Cost - Calculate the total cost of all the selected tools.

Repeat the same format for each tool you'd like to include in your toolkit. Once you've completed your shopping list, you'll have a clear picture of how to maximize your $1500 voucher to create a comprehensive toolkit tailored to your specific needs as you embark on your electrical career.

You have three days to complete your shopping list and upload it to the class forum for discussion with the group. You may consider using a table or spreadsheet to streamline the presentation.

What we're covering:

- Power tools – angle grinders, wall chasers, bench grinders, rotary tool, heat gun.

The content in this session continues from the previous two lessons on Power Tools.

Angle Grinders

An angle grinder is used for cutting and grinding metal, masonry, and other materials. Electrical workers use angle grinders for cutting conduit, metal plates, hardy board, and removing rust or paint from metal surfaces. Angle grinders are available in different sizes and power options. They can be corded or cordless, with corded models providing more power for heavy-duty tasks.

Wall Chasers

Wall chasers are essential power tools used by electricians for installing wires in walls. They are designed with twin blades that create narrow channels in the walls to accommodate cables and conduits.

These tools save significant time and effort as they allow clean and accurate cutting of grooves and channels in walls. Wall chasers are powered by electric motors that drive electric discs, similar to those found in angle grinders. For a dust-free working environment, wall chasers with a vacuum cleaner connection are highly desirable as they effectively collect the generated dust during operation.

Qualities to Look for in Wall Chasers:

- Lightweight and Ergonomic Design: The best wall chasers should be light in weight to minimise operator fatigue during extended use. An ergonomic D-shape handle further enhances user control, especially during heavy-duty operations.

- Special Guards for Chip Ejection: To ensure secure work, wall chasers should come equipped with special guards that prevent chip ejection while working. This feature contributes to the safety of the operator and surrounding areas.

- Advanced Channel Width and Cutting Depth Adjustments: Wall chasers should offer advanced adjustments for channel width and cutting depth. This versatility allows them to perform various operations effectively and efficiently.

Bench Grinders

Bench grinders are versatile power tools commonly used for various tasks related to metalwork and sharpening tools. They consist of a motor-driven grinding wheel mounted on a sturdy workbench, providing stability and precision during use.

For electricians, bench grinders serve multiple purposes and offer several benefits:

- Tool Sharpening: Electricians use a wide array of hand tools, such as screwdrivers, pliers, and wire strippers. Bench grinders are ideal for sharpening these tools, restoring their cutting edges and functionality.

- Deburring and Cleaning: A bench grinder with a wire wheel attachment can quickly remove burrs or rough edges on metal components, ensuring smooth and safe installations.

- Metal Shaping: Bench grinders equipped with grinding wheels of different grits can be used to shape and modify metal surfaces as required.

- Removing Rust and Paint: Bench grinders, especially with a wire wheel or a sanding disc attachment, are excellent for removing rust and old paint from metal surfaces.

- Cutting and Polishing: Some bench grinders come with cutting or polishing attachments, allowing electricians to cut metal rods or polish finished metalwork for a professional appearance.

- Precision Work: The stable platform of a bench grinder enables precise control during grinding, making it suitable for delicate tasks that require accuracy, such as shaping small metal parts or sharpening fine tools.

It is crucial to observe safety practices and use the bench grinder with care to prevent accidents and injuries. Always wear appropriate personal protective equipment, such as safety goggles and gloves, to safeguard against sparks and debris. Ensure the workpiece is securely clamped to prevent accidents and maintain control during grinding. Avoid excessive pressure on the grinding wheel to prevent overheating and premature wear.

Rotary Tool (Dremel)

A rotary tool, commonly known as a Dremel, is a handheld tool with various attachments, such as grinding wheels and cutting discs, for precision work. Electrical workers use rotary tools for tasks like grinding, polishing, and cutting small items or making precise modifications to electrical components. Rotary tools come in corded and cordless variants, with cordless models offering better mobility.

Heat Guns

A heat gun is a handheld tool that emits a stream of hot air. It is used for various applications, including stripping paint, soldering, and shrinking heat shrink tubing.

Electrical workers use heat guns for tasks like soldering wires, removing heat-shrink tubing, and bending plastic conduits. Heat guns can be corded or cordless, with adjustable temperature settings.

Exercise 10

Consolidate your knowledge of power tools by completing the table in the downloadable worksheet here.

Self-directed Learning

Continue ‘spending’ your $1500 voucher and creating your table or spreadsheet.

What we're covering:

- Meters and testers - multifunction, voltage tester, IR, multi-meter, clamp-on ammeter, phase rotation, circuit finders, line locators.

- AS/NZS 3017:2022 AS/NZS 3760:2022

The scope of electrical work you engage in, as well as the testing requirements, will determine the specific type of test equipment you will need in your tool kit.

Remember that after checking an electrical installation visually, tests should be carried out in accordance with AS/NZS 3000:2018, Clause 8.3.3. These tests make sure the installation meets the standard requirements and is safe for its intended use.

You must adhere to the Electricity (Safety) Regulations, ESR 63 and ESR 90, which mandate testing for all prescribed electrical work on installations and appliances and in order to perform these tests effectively, you must possess suitable and compliant test equipment.

AS/NZS 3017:2022 is a guide for inspecting and testing low voltage electrical setups. It ensures they comply with safety rules to prevent fires and protect people and animals from electric shocks. This guide applies to installations connected to an MEN system. Use AS/NZS 3017:2022 to meet the Periodic Verification needs of both the Electricity (Safety) Regulations 2010 and AS/NZS 3019:2007. It contains helpful checklists for visual inspection and testing, which electricians should keep handy. By using these checklists along with AS/NZS 3000:2018, you can ensure electrical setups are safe and meet the standards.

Selecting the right test equipment:

- Assess Your Testing Needs: Consider the specific tests you will need to conduct. Understanding your requirements will help you make informed decisions when choosing the appropriate equipment. (See the table below.)

- Conduct Research: Before making any purchases, conduct thorough research. Seek advice from experienced electrical practitioners and explore various suppliers of testing equipment. Evaluate whether a particular meter is fit for your intended purpose, ensuring it offers accuracy, appropriate overvoltage category rating (cat rating), suitable resolution, test values, and the required ranges.

- Comprehend Specifications: Review the specifications of potential test equipment. If you don't understand some of the technical jargon, seek guidance from someone knowledgeable in the field. Understanding these specifications is crucial to selecting the right tools.

- Choose Reputable Brands: Select reputable and reliable brands known for producing robust, good-quality equipment. Additionally, look for products that come with after-sales warranties, providing you with added assurance.

The following table, created by the Electrical Workers Registration Board summarises the types of test instrument required for various measurements:

| Testing Instrument measuring | ||

|---|---|---|

| Voltage AC and DC | Dedicated voltage tester. | Should be capable of reading all working voltages, both AC&DC. |

| Resistance | 500V DC Insulation resistance (IR) tester or incorporated in multifunction tester. | For testing a 400V 3 phase or 230V single phase installation a 500V DC test voltage is required as a minimum. |

| Resistance | Multi-meter or incorporated in multifunction tester. | Multi-meter should be rated Cat III. |

| Current | Clamp-on Ammeter. | Cat III clamp-on ammeter capable of reading all load requirements. |

| Leakage Current | Leakage current clamp-on Ammeter. | Cat III high resolution clamp-on ammeter capable of milliamps. |

| Fault Loop-Impedance | Incorporated in multifunction tester. | Cat III or IV. |

| RCD Testing | Incorporated in multifunction tester. | Capable of 30mA and 10mA RCD tests. |

| Phase Rotation | Phase rotation tester. | Contactless meter offers more safety. |

Multifunction Tester

Multifunction testers are widely available from major electrical test equipment manufacturers. You can easily find information about different brands and models by searching online or asking electrical wholesalers for guidance.

The main advantage of multifunction testers is that they combine multiple testing functions in one device. This makes it efficient for electrical workers to perform all the necessary tests required to meet AS/NZ Standards and regulations. It simplifies the testing process and is useful for various electrical tasks.

While multifunction testers can do many tests, it's also helpful to consider having separate specialised tools for specific tasks. This can improve precision and efficiency, especially for complex projects. Having separate instruments can act as a backup in case one fails, ensuring work continues without interruptions. Additionally, using separate meters for different jobs can boost productivity, enabling multiple tasks to be done simultaneously. This is particularly useful for bigger projects or when multiple teams are working together.

Some of the key functions performed by multifunction testers include:

- Insulation Resistance Testing: This test measures the resistance between conductive parts and the earth, ensuring the effectiveness of insulation in electrical circuits and identifying potential leakage paths or insulation breakdowns.

- Earth Loop Impedance Testing: Earth loop impedance testing evaluates the impedance or resistance of the earth connection in the event of a fault, ensuring that fault currents can be safely discharged, minimising the risk of electric shock.

- RCD (Residual Current Device) Testing: RCDs are critical safety devices that protect against electric shocks by rapidly disconnecting the power supply during a fault. Multifunction testers can verify the proper functioning and safety limits of these devices.

- Polarity Testing: Polarity testing checks the correct connections of live, neutral, and earth conductors in an electrical system. Proper polarity ensures that electrical appliances and equipment function as intended, reducing the risk of electrical faults.

- Continuity and Resistance Measurement: Multifunction testers can measure continuity and resistance in electrical circuits, helping to detect loose connections, faulty wiring, or damaged components.

- Voltage and Current Measurement: These testers can also measure voltage and current in both AC and DC circuits, providing valuable information about the electrical system's performance.

- Phase Sequence Testing: In three-phase electrical systems, a multifunction tester can determine the correct sequence of phases, ensuring that motors and machinery run in the intended direction.

- Data Logging and Reporting: Many multifunction testers come equipped with data logging capabilities, allowing electricians to store test results for analysis and documentation. Detailed reports can be generated for compliance and regulatory purposes.

- Frequency and Capacitance Measurement: Some advanced multifunction testers offer additional functions, such as measuring frequency and capacitance, providing more comprehensive insights into electrical systems.

Dedicated Voltage Tester

A voltage tester is a handheld device used to quickly check if a circuit or appliance is energised, before working on it. The simplest and safest type of voltage tester is the non-contact voltage tester, powered by batteries, which can detect electricity by being close to an outlet slot or wire.

It is essential to use a voltage tester to detect AC voltages on sockets, switches, outlets, and circuit breakers before commencing an electrical project.

The voltage tester's indicator, often a light-emitting diode (LED), illuminates if voltage is present, indicating the need to shut down the current before starting work. This is a vital safety measure required by health and safety legislation.

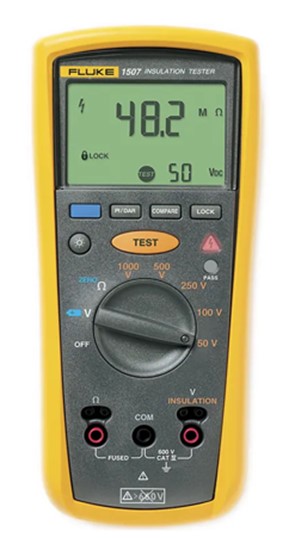

Insulation Resistance (IR) Tester

An Insulation Resistance (IR) Tester is a specialised test instrument used to evaluate the integrity of insulation in electrical systems. The primary purpose of this tester is to detect insulation leakage between live conductors and between live conductors and earth. It helps electricians and electrical professionals identify potential faults, weaknesses, or breakdowns in the insulation of electrical circuits and appliances. It works by applying a test voltage to the circuit being examined and measuring the resistance of the insulation.

Regularly conducting insulation resistance tests is essential for maintaining the reliability and safety of electrical installations. Electricians often use the IR tester during maintenance, troubleshooting, and safety inspections to ensure that insulation is performing as expected. When using the IR tester, proper safety precautions must be followed, including de-energizing the circuit before performing the test.

According to AS/NZS 3000:2018 8.3.6.1, the IR tester must maintain the terminal voltage within +20% and -10% of the nominal open circuit voltage while measuring a resistance of 1 MΩ on the 500V range or 10 MΩ on the 1000V range.

Multi-Meter

A multimeter is a versatile digital tool combining multiple functions into a single device. It can read a wide range of electrical parameters, including:

- Voltage: Multimeters can measure both AC (alternating current) and DC (direct current) voltage. They are used to determine the potential difference between two points in an electrical circuit.

- Current: Multimeters can measure both AC and DC currents flowing in a conductor. They allow electricians to determine the amount of current passing through a circuit.

- Resistance: Multimeters can measure the resistance of an electrical component or circuit. Resistance refers to the opposition of current flow in a conductor.

- Continuity Testing: Multimeters can check for continuity, which determines if a circuit is complete and capable of conducting electricity. It is often used to identify open circuits or faulty connections.

- Diode Testing: Some multimeters have a diode testing function, which helps check the health of diodes in electronic circuits.

- Capacitance: Advanced multimeters can measure capacitance, which determines the ability of a component to store an electrical charge.

- Frequency: Certain multimeters can measure the frequency of an AC signal, which is the number of cycles per second.

- Temperature: Some multimeters come with temperature measurement capabilities, often using a thermocouple probe.

- Duty Cycle: Duty cycle measurement allows you to assess the percentage of time a digital signal is high (on) compared to the total period.

- Non-Contact Voltage Detection: Some multimeters have a non-contact voltage detection feature, which allows them to detect the presence of AC voltage without making direct contact.

Clamp-On Ammeter

Clamp-on ammeters are non-invasive electrical testing instruments used to measure AC and DC currents without disconnecting wires. They are similar to a standard tester or multimeter with the addition of a clamp/jaw that reads amperage on large diameter conductors. They offer a wide range of current measurement capabilities, and many models come with additional functions like voltage, resistance, frequency, and capacitance measurements. They are widely used in various industries for electrical maintenance, troubleshooting, and inspections. Proper safety precautions and regular calibration are essential for accurate and reliable readings.

Phase Rotation Meter

Phase rotation meters, also known as phase sequence testers, are specialised electrical testing instruments used to identify the correct sequence of phases in a three-phase system. This is essential for ensuring the proper operation of motors, machinery, and other three-phase equipment.

Phase rotation meters often use non-contact testing methods, making them safe and easy to use. They can determine phase sequence without the need for physical contact with live conductors.

Many phase rotation meters feature LED indicators that display the correct phase sequence. These indicators may use arrows or numbers to show the proper sequence of phases. Some phase rotation meters also have audio indicators, such as buzzers or beeps, that provide an additional way to detect the phase sequence.

Phase rotation meters are suitable for both low-voltage and high-voltage applications, making them versatile tools for various electrical systems.

In addition to identifying phase sequence, phase rotation meters can also be used to test the rotation direction of three-phase motors, ensuring they are connected correctly.

Most phase rotation meters are portable and handheld, allowing electricians and technicians to easily carry them to different job sites.

Circuit Finders

Circuit finders, also known as circuit tracers or circuit breakers finders, are used to locate the path of live electrical circuits in walls, ceilings, or floors. They are particularly useful for finding circuit breakers, tracing wiring paths, and locating electrical faults in complex wiring systems.

Circuit finders work based on the principle of electromagnetic field detection. When an electrical current flows through a conductor, it generates a magnetic field around it. The circuit finder's transmitter unit is connected to the electrical circuit or breaker panel. It injects a signal into the circuit, which creates a magnetic field along the path of the live wires. The handheld receiver unit is then used to detect the magnetic field and trace the path of the live wires, allowing electricians to identify the course of hidden electrical lines.

Line Locators

Line locators, also called line tracers or underground cable locators, are used to locate underground or buried electrical cables, pipes, or other conductive materials before excavation or construction work, preventing accidental damage to buried utilities. They work based on the principle of electromagnetic induction. When an alternating current is applied to an electrical cable, it generates an electromagnetic field around the cable.

The line locator's transmitter unit applies an alternating current to the cable, creating an electromagnetic field that radiates outward. The handheld receiver unit is then used to detect the electromagnetic field and pinpoint the location of the underground cable, allowing electricians to trace its path without digging.

A Final Word about Test Equipment Selection…

When choosing an electrical test instrument, it is essential to prioritize safety and ensure the meter is suitable for the intended use. Here are some key steps to follow:

- Understand Measurement Categories: Begin by identifying the measurement categories (Cat II, Cat III, Cat IV) suitable for your specific tasks. This ensures that the test instrument is appropriate for the electrical environment it will be used in.

- Verify Electrical Safety Standards: Look for the correct electrical safety standard applicable to the test instrument you need. Ensure it complies with the relevant safety regulations to guarantee safe operation.

- Seek Independent Type Testing: Check if the test instrument has undergone independent type testing to the safety standard mentioned. This provides assurance that the meter meets safety requirements and has been rigorously tested.

- Check Warning Labels and Markings: Inspect the test instrument for warning labels or markings that indicate its safe use, potential hazards, and operating instructions. Adhere to these instructions to prevent accidents or damage.

- Review Specifications: Examine the meter's specifications to assess its performance capabilities objectively. Pay close attention to accuracy, resolution, range, and precision, considering all these factors together to make an informed decision.

- Ensure your test instruments undergo annual testing and recalibration by an approved supplier to maintain their accuracy at an acceptable level. It's crucial that your test instrument carries a calibration certificate; otherwise, recorded results may become invalid.

- To keep your meter operational and safe, periodically verify its accuracy. For common (non-specialist) meters used in regular installation work, routine accuracy checks of calibration are straightforward and quick. It's highly recommended to perform these checks regularly and document the results. However, if you find that the meter is out of calibration, you should send it to an accredited laboratory for correction. These routine checks are not a substitute for accredited calibration.

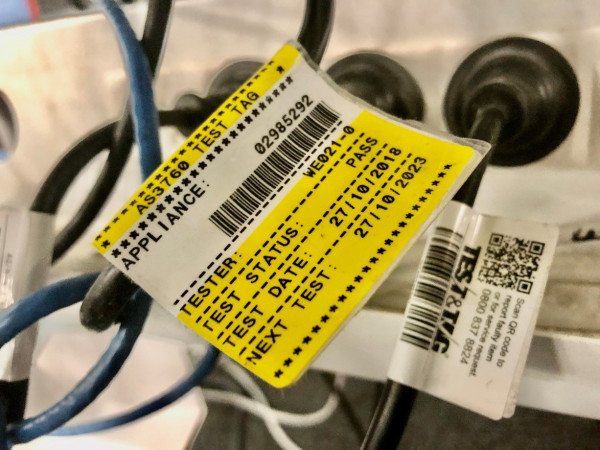

AS/NZS 3760:2022 – Ensuring electrical safety through in-service inspection and training

Introduction

AS/NZS 3760:2022 plays a vital role in promoting electrical safety and compliance with regulations in Australia and New Zealand. This standard serves as the foundation for testing and tagging electrical equipment, with a strong emphasis on ensuring user safety.

Scope and Applicability

AS/NZS 3760:2022 is applicable throughout the lifecycle of electrical equipment. It addresses situations when equipment is put into service for the first time, in use, available for second-hand sale or hire, or has undergone servicing or repair. This latest version focuses on inspection and testing guidelines for Class I and Class II appliances, functional earthing, insulation, leakage current, RCD tripping times, cord sets, and earth continuity resistance.

Safety Focus

The primary objective of AS/NZS 3760:2022 is to guarantee the safety of electrical equipment used in diverse settings, including workplaces, homes, and public spaces. The standard outlines a systematic approach to inspecting and testing electrical equipment, aiming to identify defects, damage, or wear that could lead to unsafe conditions. By concentrating on safety concerns, AS/NZS 3760 ensures that equipment remains electrically sound and properly connected, minimising the risks of electric shock and fire hazards.

Inspection and Testing Procedures

AS/NZS 3760:2022 outlines comprehensive testing procedures, including visual inspections, insulation resistance tests, earth continuity tests, and polarity tests. These measures serve to assess the equipment's condition and its ability to prevent hazards effectively. The standard's emphasis on visual inspections, which can detect over 90% of defects, accounts for environmental hazards and the equipment's wear during testing.

Frequency of Inspections

The recommended inspection and testing frequencies within AS/NZS 3760:2022 are contingent upon equipment type, intended use, and environmental conditions. Regular inspections and testing are crucial in identifying and rectifying potential issues before they escalate into more serious safety risks.

Record Keeping and Compliance

AS/NZS 3760:2022 necessitates the maintenance of records detailing testing outcomes, including the tester's name, testing date, results, and the next scheduled testing date. This record-keeping system ensures accountability and traceability, contributing to overall compliance with safety regulations.

Role in Workplace Safety

AS/NZS 3760:2022 assumes a pivotal role in workplace safety by overseeing the Test and Tag industry regarding portable appliance electrical safety. It sets recommendations for testing various types of electrical equipment commonly found in workplaces, emphasizing test and tag frequencies, inspection and testing specifications, and record-keeping guidelines.

Self-directed Learning

What we're covering:

- Personal Protective Equipment Potential hazards associated with power tool and appropriate PPE.

Power tools are widely used to perform tasks efficiently and effectively. However, using power tools involves inherent risks, especially when working with electricity. Identifying appropriate Personal Protective Equipment (PPE) and electrical safeguards is crucial to ensure the safety of operators and those nearby.

Understanding power tool hazards

Before identifying PPE and electrical safeguards, it is important to recognize the potential hazards associated with power tool use:

- Electrical shock: Power tools connected to electrical sources can pose a risk of electric shock, leading to severe injuries or fatalities.

- Mechanical hazards: Moving parts of power tools, such as rotating blades, drills, or abrasive wheels, can cause cuts, abrasions, or amputations.

- Noise exposure: Many power tools generate high noise levels, leading to hearing damage or loss if not adequately protected.

- Vibration hazards: Prolonged use of power tools can result in hand-arm vibration syndrome (HAVS) or whole-body vibration-related health issues.

- Flying Debris: Some power tools, like drills and grinders, can produce flying debris that may cause eye injuries or lacerations.

- Kickback: Tools with rotating components, such as saws and grinders, can experience kickback if the blade binds or pinches, leading to loss of control.

- Dust and Fume Exposure: Cutting and grinding generate dust and fumes that can be harmful when inhaled, potentially causing respiratory issues.

- Burn Hazards: Heat guns can cause burns if users touch the hot nozzle or direct heat at their skin.

- Fire Hazards: Certain power tools, like heat guns and grinders, can generate sparks and ignite fires, especially when used near flammable materials.

- Over-tightening: Cordless screwdrivers pose a risk of over-tightening screws, leading to damaged workpieces and potential accidents.

- Hand Strain: Prolonged use of power tools can cause hand and arm strain, leading to fatigue and musculoskeletal injuries.

Exercise 11

Consider the hazards associated with the power tools covered earlier in this course. Complete the table in this worksheet, providing at least two hazards for each and a brief explanation. The first one has been done for you.

Identifying appropriate PPE for power tool use

Personal Protective Equipment (PPE) is the first line of defense against potential power tool hazards. It includes various protective gear and equipment designed to reduce the risk of injuries. Wherever possible equipment should be non-conductive materials and rated at or above the voltage being worked on.

Electrical PPE may include safety glasses, face shields, hoods, hard hats, hearing protection, electrical hazard rated safety shoes, insulating rubber gloves with leather protectors, insulated sleeves, and arc rated clothing, depending on the tasks.

Prior to wearing PPE, you should:

- Perform a PPE hazard assessment and determine the PPE needed to provide protection.

- Obtain training on the proper use of PPE for working on or near exposed energised parts.

- Inspect and test PPE to ensure the equipment is not damaged or defective.

- Ensure your PPE is clean and free of liquid stains, oils or greases, or debris.

Be sure to:

- Use PPE according to manufacturers’ requirements.

- Perform tasks wearing required PPE.

- Use ALL required PPE.

Eye and Face Protection

Nonconductive safety glasses or goggles with side shields should be worn to shield the eyes from flying debris or particles, dust, splashing substances, harmful gases, vapors, aerosols, and high intensity radiation from welding operations. Consider anti-fog coatings on safety goggles to prevent fogging, ensuring clear vision even in humid or cold conditions. This feature is particularly advantageous when working in confined spaces or areas with temperature.

Face shields or visors with the appropriate arc flash rating may be necessary for some electrical work. Safety glasses or goggles should be worn underneath face shields.

AS/NZS 1336:2014 Eye and face protection - Guidelines

Provides recommended practices and guidance for the selection, care and use of eye and face protectors worn in occupational environments to protect eyes and faces against hazards, such as flying particles and fragments, and exposure to optical radiation occurring in industrial processes, such as welding.

Head Protection

Nonconductive hardhats should be worn whenever there is a danger of head injury from electric shock or burns due to contact with live parts, being struck by flying or falling objects, or by striking one’s head against a fixed object.

AS/NZS 1801:1997 Head Protection Occupational protective helmets

This standard outlines the specifications for three types of protective helmets based on their intended use. It covers the construction of the helmet shell and finish, along with the testing methods. Furthermore, it includes specific additional performance criteria for occupational protective helmets used in high-temperature workplaces and for bushfire fighters' helmets, which are based on industrial helmets.

Hearing Protection

When using noisy power tools, ear plugs, earmuffs or helmets with integrated hearing protection must be worn to prevent hearing damage. When selecting hearing protection, electricians should consider the Noise Reduction Rating (NRR) indicated on the product. The higher the NRR value, the better the protection from loud noises. It's essential to ensure the chosen hearing protection provides sufficient noise reduction for the specific power tools and workplace environment.

AS/NZS 1270:2002 Acoustics - Hearing protectors

This standard outlines the criteria for the design, material, and effectiveness of standard hearing protectors. It also offers guidelines for specialist hearing protectors and procedures to physically and acoustically test these devices.

Hand Protection

Choose gloves based on the specific job requirements and potential hazards involved, balancing the need for cut resistance with other safety considerations, such as dexterity and protection against electrical hazards.

While non-conductive gloves are essential for electrical work involving live circuits, they might not be the most suitable option when using power tools. For power tool usage, prioritise gloves that offer protection against cuts, abrasions, and vibrations. Cut-resistant gloves are particularly important as they can safeguard against potential injuries from sharp edges, jagged sheet metal, and other hazardous objects encountered while working with power tools.

AS/NZS 2161.2:2020 Occupational protective gloves, Part 2: General requirements and test methods

This standard explains the general requirements and test methods for occupational protective gloves. It adopts the international standard ISO 21420:2020 but with some changes specific to Australia and New Zealand. The standard covers various aspects of protective gloves, including their design, construction, safety, comfort, and effectiveness. It ensures that gloves are safe to use, do not cause harm, and provide the intended protection for the hands.

Respiratory Protection

Respiratory Personal Protective Equipment (PPE) is essential for workers who use power tools in environments where airborne hazards, such as dust, fumes, and particles, are present. These hazards can arise from cutting, grinding, sanding, or other processes involving power tools.

The respiratory PPE is designed to protect the user's respiratory system from inhaling harmful substances that may cause respiratory issues or long-term health problems.

Types include disposable dust masks, half-face respirators, full-face respirators, and powered air-purifying respirators (PAPRs). Choose based on hazard type, filter efficiency, fit, comfort, and maintenance.

There are two standards covering personal respiratory protection and risk management. These standards form a basis for the selection, use and maintenance of RPE in Australian and NZ workplaces. When respirator use is required in the workplace, respirators shall conform to the requirements of AS/NZS 1716.

AS/NZS 1715:2009 Selection, use and maintenance of respiratory protective equipment. This standard offers information to employers and users on different types of RPE, how to select the right type for the job and how to correctly maintain it.

AS/NZS 1716:2012 Respiratory protective devices offer information to manufacturers, suppliers, employers and users by setting out performance requirements for different types of RPE.

Foot Protection

Foot protection is essential for electricians and other workers using power tools. Your feet are vulnerable to various workplace hazards, including falling objects, sharp materials, electrical shocks, or potential crushing incidents. Proper PPE ensures safety and prevents injuries in the workplace.

Types of Foot Protection include:

- Steel-Toed Boots: Have a reinforced steel cap in the toe area for protection against heavy objects and compression hazards.

- Composite-Toed Boots: Feature non-metallic toe caps and are lighter, suitable for electricians working in potentially energised environments.

- Electrical Hazard (EH) Rated Boots: Provide insulation against electric shocks with insulated soles and heels.

- Metatarsal Guards: Added protection for the metatarsal bones to safeguard against impacts and falling objects.

Properly fitted safety boots provide stability and reduce the risk of slips and falls while using power tools. They protect feet from impacts, falling objects, and sharp materials encountered while using power tools. Wearing appropriate foot protection also ensures compliance with workplace safety regulations.

AS/NZS 2210.3:2009 Occupational protective footwear - Specification for safety footwear specifies basic and additional (optional) requirements for safety footwear.

General Body Protection Gear

General body protection gear will also safeguard against potential hazards when using power tools. Consider protective clothing such as: Overalls or long-sleeved shirts to shield the skin from sparks, hot materials, and chemical splashes during power tool usage and other electrical tasks.

Flame-resistant, non-conductive, natural fibre clothing when working with power tools near flammable materials or in high-heat environments to prevent burns.

Choose high-visibility vests to enhance visibility and safety, especially in low-light conditions or when working near moving vehicles.

Kneepads

Kneepads provide cushioning and support to protect the knees from impact and potential injuries caused by kneeling or crawling on hard surfaces.

They also help prevent long-term knee problems, such as joint pain and inflammation, arising from repetitive kneeling and bending.

Fall Protection

When working with power tools at heights or on elevated surfaces, you must ensure you have the appropriate fall protection equipment in place. This includes wearing harnesses and using other safety gear such as belts, pole straps, supports, tennis elbow braces etc.

AS/NZS 1891.1:2020 Personal Equipment for Work at Height, Part 1: Manufacturing requirements for full body combination and lower body harnesses specifies requirements for the materials, design, manufacture, testing and marking of full-body, combination, and lower-body harnesses designed for working at height.

Self-directed Learning

Matching Power Tool Scenarios, Hazards, and Correct PPE